Designing Highly Reversible and Stable Zn Anodes for Next

The global imperative for sustainable energy has catalyzed the pursuit of next-generation energy storage technologies that are intrinsically safe, economically viable, and

Get Price

Liquid metal anode enables zinc-based flow batteries with

Here, we developed a liquid metal (LM) electrode that evolves the deposition/dissolution reaction of Zn into an alloying/dealloying process within the LM, thereby

Get Price

Aqueous Zinc-Based Batteries: Active Materials,

Aqueous zinc-based batteries (AZBs) are emerging as a compelling candidate for large-scale energy storage systems due to their cost

Get Price

Review of zinc dendrite formation in zinc bromine redox flow battery

The zinc bromine redox flow battery (ZBFB) is a promising battery technology because of its potentially lower cost, higher efficiency, and relatively long life-time. However,

Get Price

Zinc–bromine battery

A zinc-bromine battery is a rechargeable battery system that uses the reaction between zinc metal and bromine to produce electric current, with an electrolyte composed of an aqueous solution

Get Price

Advanced Materials for Zinc-Based Flow Battery: Development

Herein, the focus is on the scientific understandings of the fundamental design of these advanced materials and their chemistries in relation to the battery performance.

Get Price

Recent advances in aqueous manganese-based flow batteries

Coupling with zinc [52, 53], sulfur [54], or iron [55, 56] in alkaline media makes it a promising candidate for applications in alkaline-based redox flow batteries due to its high

Get Price

Dynamics of zinc dendritic growth in aqueous zinc-based flow batteries

Consequently, the understanding of the morphological instability and the growth dynamics of electrodeposited dendrites on the zinc metal anodes is vital for regulating

Get Price

Improved electro-kinetics of new electrolyte composition for

Research Article Improved electro-kinetics of new electrolyte composition for realizing high-performance zinc-bromine redox flow battery Yogapriya Vetriselvam a 1 #,

Get Price

A Neutral Zinc–Iron Flow Battery with Long Lifespan and High

Herein, sodium citrate (Cit) was introduced to coordinate with Zn 2+, which effectively alleviated the crossover and precipitation issues. Meanwhile, the redox species

Get Price

Compressed composite carbon felt as a negative electrode for a zinc

However, zinc-based flow batteries involve zinc deposition/dissolution, structure and configuration of the electrode significantly determine stability and performance of the battery.

Get Price

Alkaline zinc-based flow battery: chemical stability,

This paper reports on details of chemical stability of the zinc metal exposed to a series of solutions, as well as the relationship between the morphological evolution of zinc electrodes

Get Price

Perspectives on zinc-based flow batteries

In this perspective, we first review the development of battery components, cell stacks, and demonstration systems for zinc-based flow battery technologies from the

Get Price

Adaptive Zincophilic-Hydrophobic Interfaces via Additive

While aqueous Zn battery additives have been extensively explored, systematic selection criteria for high-areal-capacity Zn-FBs remain absent. Here, we establish

Get Price

Exploring the Performance and Mass-Transfer

Zinc-based hybrid-flow batteries are considered as a promising alternative to conventional electrochemical energy-storage systems for

Get Price

Designing interphases for practical aqueous zinc flow

We investigated artificial interphases created using a simple electrospray methodology as a strategy for addressing each of these challenges.

Get Price

Review of zinc-based hybrid flow batteries: From fundamentals to

Despite various flow battery chemistries, only the all-vanadium, zinc-bromine, zinc-cerium, zinc-nickel and zinc-iron (zinc-ferricyanide) systems have successfully been scaled-up

Get Price

Cost-effective iron-based aqueous redox flow batteries for large

The iron-based aqueous hybrid flow battery (IBA-HFB) typically adopts active species which can be electrodeposited as a solid layer during the operation [60, 132].

Get Price

A Safe, High-Performance, Rechargeable, Recyclable Zinc

The three-dimensional zinc sponge structure eliminates dendrite growth and has a high surface area, resulting in a battery with a high energy density comparable to lithium-based batteries,

Get Price

Designing interphases for practical aqueous zinc flow batteries

We investigated artificial interphases created using a simple electrospray methodology as a strategy for addressing each of these challenges.

Get Price

Membrane with horizontally rigid zeolite nanosheet arrays against zinc

Zinc-based flow batteries are recognized as one of the most promising stationary energy storage systems due to their advantages of high energy density and low cost.

Get Price

Balancing current density and electrolyte flow for improved zinc

However, the irregular deposition of zinc on electrodes hinders the widespread utilization of rechargeable ZABs due to limited durability and stability. This study investigates

Get Price

A Neutral Zinc–Iron Flow Battery with Long Lifespan

Herein, sodium citrate (Cit) was introduced to coordinate with Zn 2+, which effectively alleviated the crossover and precipitation issues.

Get Price

Recent advances in material chemistry for zinc

His research focuses on high-performance cathodes for zinc-based redox flow batteries, sodium-ion batteries and Density Functional Theory

Get Price

Liquid metal anode enables zinc

Zinc- based flow batteries (Zn- FBs) are promising candidates for large- scale energy storage because of their intrin-sic safety and high energy density. Unlike that

Get Price

Liquid metal anode enables zinc-based flow batteries

Here, we developed a liquid metal (LM) electrode that evolves the deposition/dissolution reaction of Zn into an alloying/dealloying process within

Get Price

Impact of electrolyte composition on the performance of the zinc

Abstract The zinc–cerium redox flow battery has the highest open circuit cell voltage (Ecell = 2.4 V) of all the common redox flow battery (RFB) systems being investigated. In this

Get Price

Aqueous Zinc-Based Batteries: Active Materials, Device Design,

Aqueous zinc-based batteries (AZBs) are emerging as a compelling candidate for large-scale energy storage systems due to their cost-effectiveness, environmental friendliness,

Get Price

6 FAQs about [Zinc-based flow battery composition]

What is a zinc-based flow battery?

Since the 1970s, various zinc-based flow batteries have been proposed and developed by coupling with different positive electrode reactions . Together with the all-vanadium system, zinc-based systems are one of the few flow battery chemistries to be scaled-up and commercialized, for various applications.

What is a zinc based battery?

And the zinc-based batteries have the same electrolyte system and zinc anode as zinc–air batteries, which provides technical support for the design of hybrid batteries. Transition metal compounds serve as the cathode materials in Zn-M batteries and function as the active components of bifunctional catalysts in ZABs.

What are the advantages of zinc-based flow batteries?

Benefiting from the uniform zinc plating and materials optimization, the areal capacity of zinc-based flow batteries has been remarkably improved, e.g., 435 mAh cm-2 for a single alkaline zinc-iron flow battery, 240 mAh cm -2 for an alkaline zinc-iron flow battery cell stack , 240 mAh cm -2 for a single zinc-iodine flow battery .

Are zinc-based flow batteries suitable for large-scale energy storage systems?

Zinc-based flow batteries (Zn-FBs) have emerged as promising candidates for large-scale energy storage (ES) systems due to their inherent safety and high energy density. However, dendrite formation and water-induced parasitic reactions at the Zn anode critically compromise long-term operational stability.

What are zinc-bromine flow batteries?

Among the above-mentioned zinc-based flow batteries, the zinc-bromine flow batteries are one of the few batteries in which the anolyte and catholyte are completely consistent. This avoids the cross-contamination of the electrolyte and makes the regeneration of electrolytes simple.

Should zinc-cerium flow batteries be developed?

The early development of zinc-cerium flow battery has been reviewed by Walsh et al. . Future work on this system should focus on low-cost, chemically stable electrodes and electrolytes to dissolve more cerium species at low acid concentrations.

More related information

-

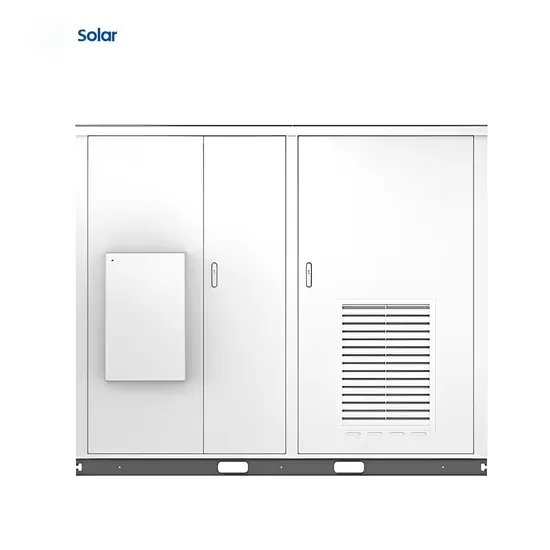

Zinc-based flow battery energy storage

Zinc-based flow battery energy storage

-

Colloidal Flow Battery

Colloidal Flow Battery

-

Solar Base Station Flow Battery Construction Plan

Solar Base Station Flow Battery Construction Plan

-

Organic flow battery manufacturers

Organic flow battery manufacturers

-

215 degree energy storage cabinet battery composition

215 degree energy storage cabinet battery composition

-

Nickel-chromium flow battery

Nickel-chromium flow battery

-

Location of flow battery solar base stations in The Gambia

Location of flow battery solar base stations in The Gambia

-

Saint Kitts and Nevis Flow Battery

Saint Kitts and Nevis Flow Battery

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.