Manual of Flat Plate Solar Collector

It is imperative that each collector be secured from falling out of the packaging, and that they be secured from scratching each other, as this may damage the collectors and lessen their

Get Price

Grid Liquid Flat Plate Solar Collectors

Collector container sides are fabricated from aluminum extrusions with an integral mounting channel. The bottom is an aluminum sheet which fits into a slot in the frame and is pop-riveted

Get Price

Materials to Use When Placing a Shipping Container

Discover the best materials for supporting a shipping container on your property. Learn which base suits your needs.

Get Price

A brief review on solar flat plate collector by incorporating the

Solar energy can also be harnessed as thermal energy using solar thermal collectors and can be used for a variety of purposes such as solar drying, cooking, distillation,

Get Price

Collector types and placement

A plausible configuration would be an entire roof slope covered with a low cost sheet-metal solar air collector. During summer an air-to-water heat exchanger should easily

Get Price

Solar Collectors Modeling and Controller Design for

Solar collectors are crucial components of a Solar Thermal Power plant (STP) which are required to be within a certain feasible range in order to

Get Price

OPTIMAL POSITION OF SOLAR COLLECTORS: A REVIEW

The solar collector has to take the optimal position that will guarantee the highest generation of heat. This paper gives a review of research with the objective of presenting, classifying and

Get Price

Collector types and placement

Evacuated tube collectors, with their extremely good insulation, can operate at higher temperatures with only very small heat losses. Because the losses are so small,

Get Price

Numerical Study of the Three-dimensional Flow in a Flat

Flat-plate collectors are the most common solar collector for solar water-heating systems in homes and solar space heating. A typical flat-plate collector is an insulated metal box with a

Get Price

In-Depth Guide to Flat Plate Solar Collectors

By integrating nanomaterials in the construction of solar collectors, researchers aim to improve light absorption and reduce the weight of the collectors. The

Get Price

Flat Plate Solar Collectors: A Comprehensive Guide to Design

This comprehensive guide will delve into the design, installation, and efficiency of **flat plate solar collectors**, providing you with the knowledge to make informed decisions.

Get Price

Flat plate solar collector networks: Design and retrofit considering

This study presents the thermohydraulic principles for retrofitting existing flat plate solar collector networks with the aim of increasing energy capture using the installed capacity.

Get Price

Flat‐Plate Collectors

In the solar collector, energy transfer is from a distant source of radiant energy to a fluid. This chapter describes flat plate collectors and explains the flat plate energy balance equation. It

Get Price

A review on analysis and development of solar flat plate collector

Based on their design, solar collectors can be classified as concentrating and non-concentrating type. Non-concentrating type can be further divided in flat plate collector and

Get Price

Flat Plate and Concentrating Collectors Explained

Explore the essentials of solar energy with our guide on flat plate and concentrating collectors, key to efficient renewable power in India.

Get Price

Analysis of a Flat-plate Solar Collector

For well-insulated collectors or concentrating collectors the stagnation temperature can reach very high levels causing fluid boiling and, in the case of concentrating collectors, the absorber

Get Price

Flat Plate Collectors Problems | PDF

The document provides 5 problems involving calculations related to flat-plate solar collectors. The first problem involves calculating the overall heat loss coefficient for a 3x6m collector using

Get Price

Shipping Container Delivery Options – Flatbed Trucks

The most common delivery method for shipping containers is using a simple flatbed semi-truck. Flatbed trucks are typically the most

Get Price

Installation Guide for Flat Plate Solar Collectors

The correct installation of flat solar thermal collectors is a decisive factor in ensuring their performance and longevity. While the product itself is designed to operate for

Get Price

Solar collector

A solar collector is a device that collects and/or concentrates solar radiation from the Sun. These devices are primarily used for active solar heating and allow

Get Price

In-Depth Guide to Flat Plate Solar Collectors

By integrating nanomaterials in the construction of solar collectors, researchers aim to improve light absorption and reduce the weight of the collectors. The result can lead to easier

Get Price

Solar Collector Spacing Calculator

Solar collector spacing calculator, this online tool provides the you with the minimum distance to next solar collector and solar water heater system array to avoid inter-row shading.

Get Price

Frequently Asked Questions for Shipping Container Site Set-Up

Answers to your frequently asked questions about modified shipping container site set-up and preparations, including plumbing and electrical questions.

Get Price

How to ensure the safety of a Flat Plate Collector?

In conclusion, ensuring the safety of a Flat Plate Collector requires a combination of proper installation, regular maintenance, and the use of safety devices. By following these

Get Price

6 FAQs about [Problem of flat-bed solar collector container placement]

Do flat plate solar collector fields affect hot water production?

However, annual hot water production using flat plates is higher. Eismann numerically analyzed the effect of pipe dimensions and arrangement on flow distribution, temperature, and pressure drops in different configurations of flat plate solar collector fields.

Do flat plate solar collectors absorb more energy?

Kizildag et al developed prototypes of flat plate solar collectors that absorb between 2.5 and 1.4 times more solar energy than standard collectors during winter and spring. This technology is based on the use of transparent insulating materials that improve efficiency.

Can flat plate solar collector networks improve efficiency?

This study analyses aspects of the design of flat plate solar collector networks, including network configuration and the effect of fouling, with the goal of improving efficiency in solar energy capture and reducing operating costs.

Why do flat plate solar collectors and collector fields scale?

The high hardness of water, elevated temperatures, and low flow velocity are factors that promote scaling formation. However, proper control of these variables can mitigate the drawbacks caused by this type of fouling. Several studies have addressed the design and optimization of flat plate solar collectors and collector fields.

How does a solar flat plate collector work?

The warmed fluid carries the heat either directly to the hot water or space conditioning equipment or to a storage subsystem from which can be drawn for use at night and on cloudy days. A precise and detailed analysis of a solar flat plate collector is quite complicated because of the many factors involved.

How to describe the thermal performance of a flat plate solar collector?

A way to describe the thermal performance of a Flat Plate Solar collector has been shown. The most important measure is the collector efficiency. A more precise and detailed analysis should include the fact, that the overall heat loss coefficient (UL) and other factors as the heat removal factor (FR) are not constant values.

More related information

-

Solar Home Container

Solar Home Container

-

How much electricity does a photovoltaic solar energy storage container use

How much electricity does a photovoltaic solar energy storage container use

-

Container House with Solar Panels China

Container House with Solar Panels China

-

Solar Pressurized Container Price in China

Solar Pressurized Container Price in China

-

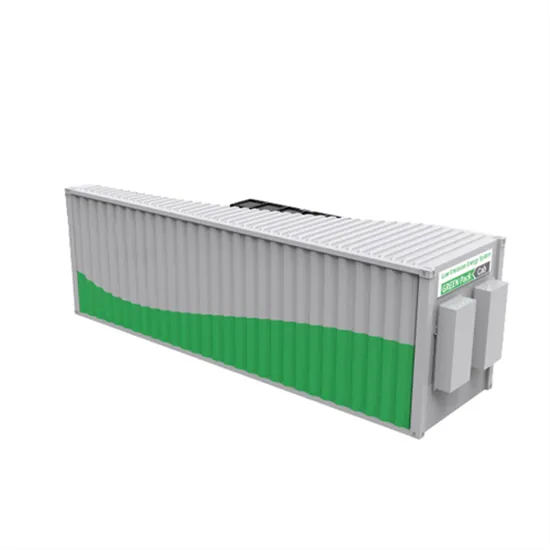

China Photovoltaic Solar Energy Storage Container Communication Power Supply

China Photovoltaic Solar Energy Storage Container Communication Power Supply

-

Chad Photovoltaic Solar Container House Sales

Chad Photovoltaic Solar Container House Sales

-

Energy storage container solar energy research and development of new alkali polishing technology

Energy storage container solar energy research and development of new alkali polishing technology

-

Togo Photovoltaic Solar Container House

Togo Photovoltaic Solar Container House

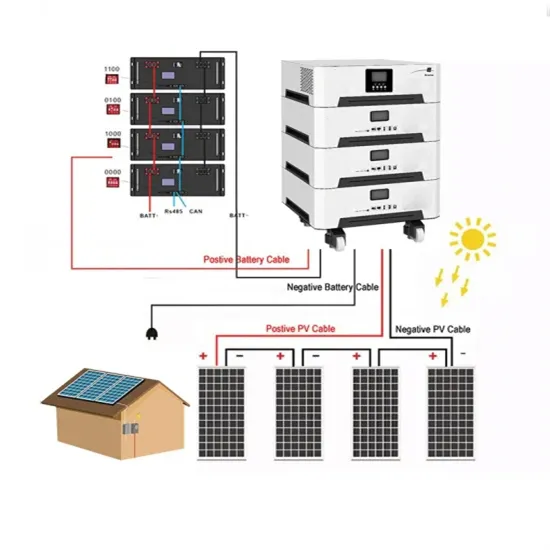

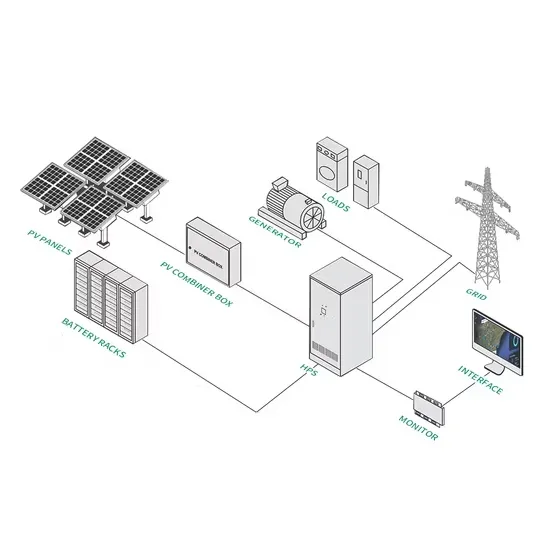

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.