Process flow diagram for square lithium-ion battery manufacturing.

A risk analysis method for potential failure modes in the lithium-ion battery assembly process based on optimized FMEA and DHHFLTS Article Full-text available Aug 2025

Get Price

DOE ESHB Chapter 3: Lithium-Ion Batteries

Lithium-ion (Li-ion) batteries represent the leading electrochemical energy storage technology. At the end of 2018, the United States had 862 MW/1236 MWh of grid-scale battery storage, with

Get Price

Square lithium battery assembly method

Lithium metal battery pouch cells (LMBPCs) are fabricated based on the proposed design strategies, containing a lithium metal anode, LNMC cathode, and tailored polypropylene

Get Price

Lithium Battery Pack Assembly: A Comprehensive Guide

Quality control is a cornerstone of the lithium battery pack assembly process. At every stage, inline testing and inspection stations

Get Price

Battery Pack Assembly Machine | Battery Pack Manufacturers | Battery

Tmax is the most professional battery pack manufacturers,we offer high quality battery pack assembly machine and battery assembly machine for battery research and manufacturing.

Get Price

Chargex US Lithium Battery Automation and Assembly Plant:

Executive Summary Chargex is excited to announce the development of a cutting-edge lithium battery automation and assembly plant in the United States. This facility marks a pivotal step

Get Price

Introduction to the manufacturing process of square

The significance of the back-end process is to activate it, and after testing, sorting, and assembly, a lithium battery product with safe use and

Get Price

Battery Pack Assembly: Techniques and Materials Used

This article delves into the techniques and materials used in battery pack assembly, emphasizing their importance in the broader EV and

Get Price

Top Lithium-ion Battery Manufacturers in Spain 2025

Spain is emerging as a key player in Europe''s lithium-ion battery industry, driven by the growing demand for electric vehicles (EVs), renewable energy storage, and industrial applications.

Get Price

Battery structure

The degree of automation in the production process of soft pack power batteries is relatively low. Square battery structure The main components of a typical

Get Price

Lifepo4 Square Lithium-Ion Battery Assembly Phosphate Solar

Product Description The main equipment of cylindrical battery pack assembly line include battery formation and grading system, battery insulation paper sticking machine, battery sorter, CCD

Get Price

BSLBATT lithium iron phosphate square module and battery pack

We adhere to long-term, continuously refine our technology, standardize our products, and systematize our production, driving rapid development in multiple fields with renewable energy solutions

Get Price

This solid-state battery factory in Europe was opened

It is reported that the construction of the plant began in the summer of 2023, covering an area of 4,500 square meters, the plant has a

Get Price

Spain begins to build its first battery factory for electric

Spain begins constructing its first lithium battery cell factory, and lithium extraction will commence in 2022. This step will minimize reliance on the Asian market

Get Price

Spain begins to build its first battery factory for electric cars

Spain begins constructing its first lithium battery cell factory, and lithium extraction will commence in 2022. This step will minimize reliance on the Asian market and gradually lower the cost of

Get Price

Spanish lithium square cell battery pack

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser

Get Price

Battery Module: Manufacturing, Assembly and Test Process Flow.

In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell Finishing. Article Link In

Get Price

Prismatic battery – a brief introduction and guide

This article provides a comprehensive guide on prismatic battery, including their definition, production process, characteristics, usage scenarios, and

Get Price

Automatic Assembly Systems

Overview We provide automatic assembly equipment for a wide variety of fields, from small batteries for consumer use, including laminated, cylindrical, square

Get Price

A Spanish company revolutionizes the lithium battery market

Thus, NCPOWER batteries offer superior performance to other types of batteries, balancing speeds 22 times faster than other lithium batteries, 50% recharges in just 30 minutes and real

Get Price

Semi-Auto Prismatic Battery Pack Assembly Line

Tmax is a professional Semi-Auto Prismatic Battery Pack Assembly Line Square Lithium ion Battery Pack Assembly Plant,Prismatic Battery Pack Assembly

Get Price

Energy Storage Battery Production Line Liquid-Cooled Square Lithium

The company is deeply engaged in the research, development and manufacturing of assembly lines and aging lines in the fields of new energy, medical devices, and commercial displays. It

Get Price

Introduction to the manufacturing process of square lithium

The significance of the back-end process is to activate it, and after testing, sorting, and assembly, a lithium battery product with safe use and stable performance is formed.

Get Price

This solid-state battery factory in Europe was opened and the first

It is reported that the construction of the plant began in the summer of 2023, covering an area of 4,500 square meters, the plant has a process process that meets current

Get Price

Lithium-Ion Battery Assembly Process & Key Stages

Explore a step-by-step guide on lithium battery pack assembly and cell making equipment. Learn the full process with expert insights.

Get Price

What are the advantages and disadvantages of square lithium

In large-scale applications, there is a problem where the system lifespan is much lower than the individual lifespan. The performance advantages and disadvantages of square

Get Price

Lithium-Ion Battery Assembly Process & Key Stages Explained

Explore a step-by-step guide on lithium battery pack assembly and cell making equipment. Learn the full process with expert insights.

Get Price

BSLBATT lithium iron phosphate square module and battery pack

We adhere to long-term, continuously refine our technology, standardize our products, and systematize our production, driving rapid development in multiple fields with

Get Price

6 FAQs about [Spanish square lithium battery assembly]

When will Spain start constructing a lithium battery factory?

Spain begins constructing its first lithium battery cell factory, and lithium extraction will commence in 2022. This step will minimize reliance on the Asian market and gradually lower the cost of automobiles equipped with lithium batteries.

What is lithium ion battery assembly process?

During charging, lithium ions migrate to the negative electrode; during discharge, they return to the positive side, producing electrical energy. The lithium-ion battery assembly process can be categorized into three key stages: 1. Front-End: Electrode Manufacturing

What are the three stages of lithium-ion battery assembly?

The lithium-ion battery assembly process can be categorized into three key stages: 1. Front-End: Electrode Manufacturing This initial phase focuses on producing high-performance electrodes, a critical step in the battery cell-making machine workflow.

When will phi4tech start a lithium battery plant in Badajoz?

Meanwhile, the Phi4Tech firm has planned a lithium battery cell plant in the Badajoz logistics platform, for which it intends to get the necessary license in the first quarter of 2022. If the project moves through as planned, construction will begin in June 2022, with the first cells leaving in 2023.

Which countries use lithium-ion batteries?

Regarding lithium-ion batteries, which are used by electric cars and most hybrids and plug-in hybrids, even though Spain is a prominent participant in Europe's automotive sector, European manufacturers have an alarming reliance on Asia.

What are the components of a lithium ion battery?

Before diving into the production process, it’s crucial to understand the core components of a lithium-ion battery: Positive Electrode: Made from materials such as lithium cobalt oxide (LCO), lithium nickel manganese cobalt oxide (NMC), or lithium iron phosphate (LFP). Negative Electrode: Typically composed of graphite.

More related information

-

Large-cell lithium battery pack assembly

Large-cell lithium battery pack assembly

-

Huawei square lithium battery

Huawei square lithium battery

-

Price of square lithium battery in Ghana

Price of square lithium battery in Ghana

-

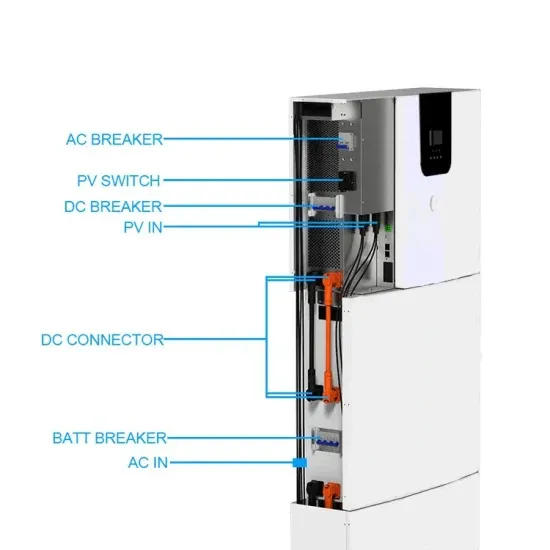

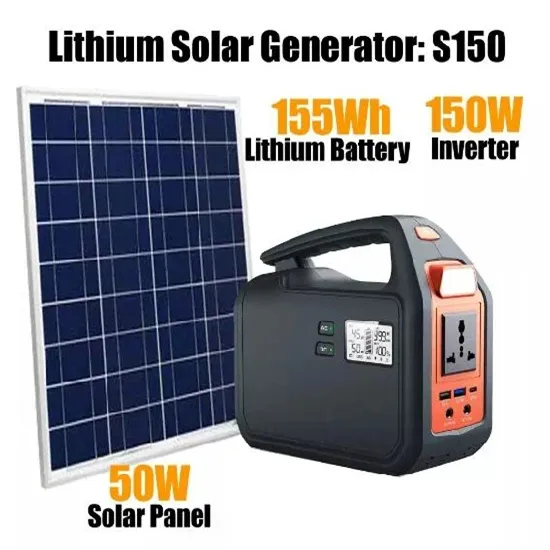

All-in-one lithium battery assembly outdoor power supply

All-in-one lithium battery assembly outdoor power supply

-

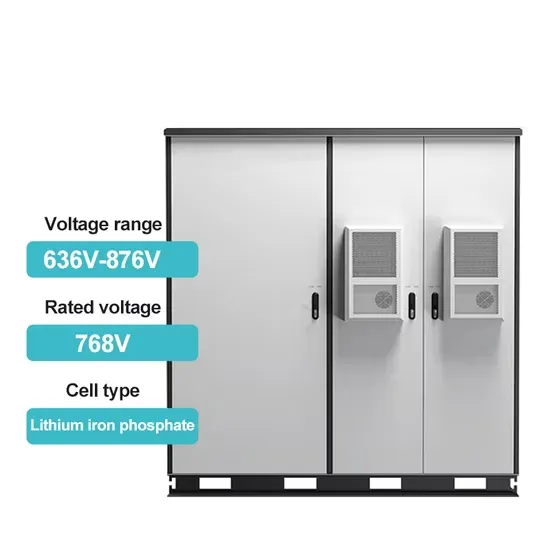

Belize high voltage energy storage lithium battery assembly

Belize high voltage energy storage lithium battery assembly

-

Square lithium battery 7 4v

Square lithium battery 7 4v

-

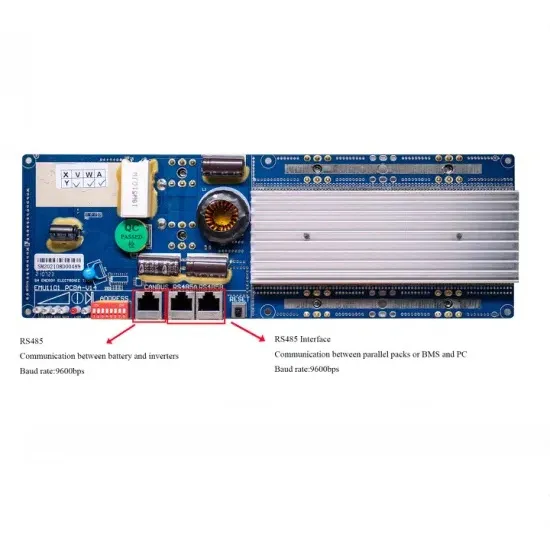

Bms large capacity square lithium battery

Bms large capacity square lithium battery

-

Pack lithium battery automatic assembly price

Pack lithium battery automatic assembly price

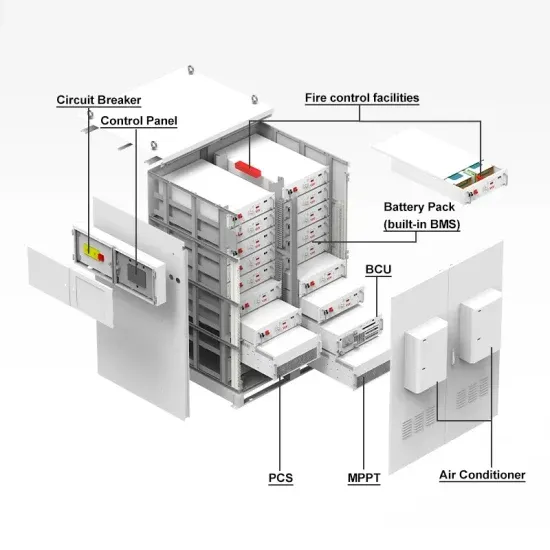

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.