EVE Energy Unveils Large Cylindrical Battery and Battery

9 hours ago· EVE Energy showcased its large cylindrical cells and pioneering Battery Passport at IAA 2025, highlighting innovations in safety, fast-charging, and full lifecycle sustainability to

Get Price

The Future of Energy Storage in Vietnam: A Fuzzy Multi-Criteria

This study addresses the need to assess and identify viable metal-ion battery alternatives to Li-ion batteries, focusing on the rapidly industrializing context of Vietnam. It

Get Price

What are the energy storage battery processes? | NenPower

At its core, energy storage requires a sophisticated understanding of both chemical and physical principles that govern battery function. Batteries operate through electrochemical

Get Price

Roll-to-Roll Battery Manufacturing: Revolutionizing

R2R manufacturing holds the promise of revolutionizing battery production, enabling scalable, cost-effective, and innovative solutions for

Get Price

Advanced battery electrode processing technologies show

Numerous market analyses have shown that over the next five years, demand for lithium-ion batteries for everything from personal electric devices to grid-scale energy storage

Get Price

Advanced electrode processing for lithium-ion battery

In this Review, we discuss advanced electrode processing routes (dry processing, radiation curing processing, advanced wet processing and 3D-printing processing) that could

Get Price

Energy Storage Manufacturing | Advanced

NREL research is investigating flexibility, recyclability, and manufacturing of materials and devices for energy storage, such as lithium-ion

Get Price

Recycling strengthens US energy & national security,

Construction on Li-Cycle''s Rochester Hub project, located in Rochester, New York, as of October 2023. Image: Li-Cycle Speaking with

Get Price

Electrode manufacturing for lithium-ion batteries—Analysis of

As modern energy storage needs become more demanding, the manufacturing of lithium-ion batteries (LIBs) represents a sizable area of growth of the technology. Specifically,

Get Price

Ultrahigh loading dry-process for solvent-free lithium-ion battery

Scalable dry electrode process is essential for the sustainable manufacturing of the lithium based batteries. Here, the authors propose a dry press-coating technique to fabricate a

Get Price

Roll-to-Roll Battery Manufacturing: Revolutionizing

Discover how roll-to-roll (R2R) manufacturing is transforming battery production. Learn about its efficiency, scalability, and advantages for

Get Price

Artificial intelligence in rechargeable battery: Advancements and

Advanced rechargeable battery technologies are the primary source of energy storage, which hold significant promise for tackling energy challenges. However, the progress

Get Price

U.S. Department of Energy Selects 11 Projects to

WASHINGTON, D.C. — The U.S. Department of Energy (DOE) today announced an investment of $25 million across 11 projects to advance

Get Price

Energy Storage Batteries manufacturing

This article explores the latest advancements, key energy storage batteries manufacturing processes, and future trends in energy storage batteries, ensuring businesses and consumers

Get Price

Taking battery manufacturing to the next level

A comprehensive review of the state of the art for battery electrode processing informs researchers, battery manufacturers and other industry stakeholders on key technical

Get Price

"north korea energy storage harness processing%2 | C&I Energy Storage

Imported Energy Storage Vehicle Processing: The 2025 Guide You Can''t Afford to Miss Ever wondered how the sleek energy storage vehicles from overseas make their way into your local

Get Price

Energy Storage Manufacturing | Advanced Manufacturing Research | NREL

NREL research is investigating flexibility, recyclability, and manufacturing of materials and devices for energy storage, such as lithium-ion batteries as well as renewable

Get Price

Profits from energy storage battery processing

Energy storage battery cells generate profits through 1. increasing demand for renewable energy solutions, 2. advancements in technology enhancing efficiency, and 3. the emergence of

Get Price

Battery Materials Processing Grants | Department of

Designed to provide grants for battery materials processing to ensure that the United States has a viable battery materials processing industry.

Get Price

Energy Storage Batteries Manufacture

The energy storage battery industry is evolving rapidly, driven by technological advancements and sustainability demands. Voltsmile remains at the forefront, delivering innovative, high

Get Price

Energy Storage & Conversion Manufacturing

To establish public-private partnerships that address manufacturing challenges for advanced battery materials and devices, with a focus on de-risking, scaling, and accelerating adoption of

Get Price

Roll-to-Roll Battery Manufacturing: Revolutionizing Energy Storage

Discover how roll-to-roll (R2R) manufacturing is transforming battery production. Learn about its efficiency, scalability, and advantages for flexible, lithium-ion, and solid-state

Get Price

Advances in Material Processing for Battery and Energy

ing and processing functions across the rapidly developing battery and energy storage industries. The information in this Folio reveals specific roadmaps to new discoveries, consistently higher

Get Price

Lithium-Ion Battery Manufacturing: Industrial View on

Lithium-ion batteries (LIBs) attract considerable interest as an energy storage solution in various applications, including e-mobility,

Get Price

Optimizing Partial Power Processing for Second-Use Battery

The price competitiveness of 2-BESS relative to other storage technologies including battery energy storage system (BESS) with new batteries relies on lowering the added costs from

Get Price

6 FAQs about [Energy storage battery processing]

What is lithium-ion battery manufacturing?

As modern energy storage needs become more demanding, the manufacturing of lithium-ion batteries (LIBs) represents a sizable area of growth of the technology. Specifically, wet processing of electrodes has matured such that it is a commonly employed industrial technique.

Can dry processing help with solid-state battery manufacturing?

Dry processing might also help with solid-state battery manufacturing as it eliminates incompatibilities between dispersion solvents, electrolytes and binders 142.

Can dry processing be used for lithium ion batteries?

In fact, for several years, multiple leading companies have been investigating the use of dry processing for battery cells. More information: Runming Tao et al, Advanced electrode processing for lithium-ion battery manufacturing, Nature Reviews Clean Technology (2025). DOI: 10.1038/s44359-024-00018-w Provided by Argonne National Laboratory

Why is scalable battery manufacturing important?

As the demand for renewable energy solutions and portable electronic devices grows, the need for efficient and scalable battery manufacturing processes has never been more critical.

Are lithium-ion batteries the future of energy storage?

Provided by Argonne National Laboratory Numerous market analyses have shown that over the next five years, demand for lithium-ion batteries for everything from personal electric devices to grid-scale energy storage is expected to grow dramatically.

What is a battery electrode manufacturing procedure?

The electrode manufacturing procedure is as follows: battery constituents, which include (but are not necessarily limited to) the active material, conductive additive, and binder, are homogenized in a solvent. These components contribute to the capacity and energy, electronic conductivity, and mechanical integrity of the electrode.

More related information

-

Finland outdoor energy storage battery processing

Finland outdoor energy storage battery processing

-

Dominic battery energy storage box processing

Dominic battery energy storage box processing

-

Turkmenistan industrial energy storage battery processing

Turkmenistan industrial energy storage battery processing

-

Maldives battery energy storage box processing company

Maldives battery energy storage box processing company

-

Battery energy storage box processing

Battery energy storage box processing

-

Lead-acid battery transformation for home energy storage

Lead-acid battery transformation for home energy storage

-

The best brand of energy storage battery

The best brand of energy storage battery

-

Hungarian photovoltaic energy storage cabinet battery factory product base station

Hungarian photovoltaic energy storage cabinet battery factory product base station

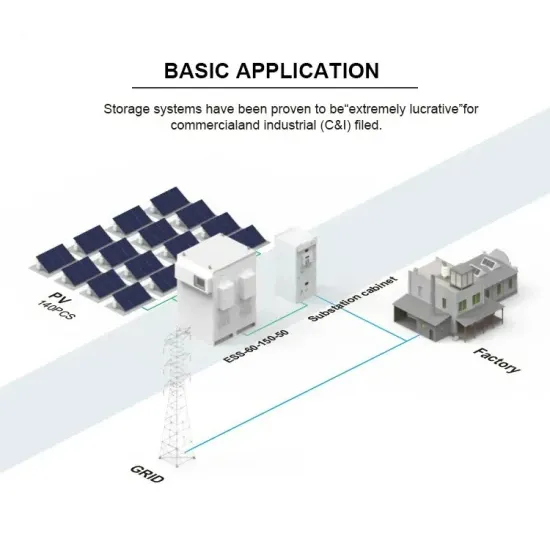

Commercial & Industrial Solar Storage Market Growth

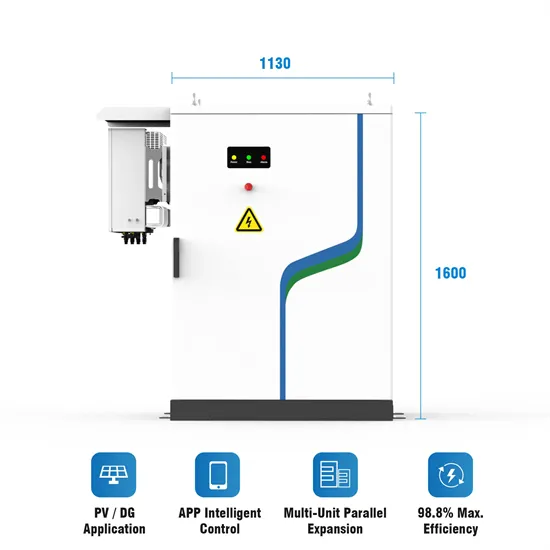

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.