Low Frequency Vs. High Frequency Inverters

Aims uses low-frequency inverters, while most Growatt inverters are high-frequency, with some exceptions. If you''re unsure whether an inverter is low or

Get Price

Comparing High Frequency UPS and Low Frequency UPS | Mingch

Uses a low-frequency inverter with a built-in transformer for better power isolation and voltage stability. Heavier and bulkier than high-frequency UPS due to including a large

Get Price

Basic Principles and Formula Analysis of Frequency

The inverter system consists of rectification, filtering, and inversion units to optimize energy conversion, reduce energy consumption, and minimize

Get Price

The difference between industrial frequency inverter and high

Because the high-frequency inverter adopts a small-sized and light-weight high-frequency magnetic core material, the power density of the circuit is greatly increased, so that

Get Price

High Frequency Inverter vs Low Frequency Inverter:

Discover the disparities between high frequency inverter vs low frequency inverter in this concise article, aiding your decision-making process.

Get Price

High frequency inverter vs low frequency inverter

This article compares high frequency inverter vs low frequency inverter from the aspects of working frequency, components, efficiency, size and weight, etc., and compares

Get Price

High frequency vs low frequency pure sine wave

While for high-frequency inverter, their electronic parts such as the MOSFETs are directly subject to load power fluctuations. With fewer PCBs,

Get Price

Power Frequency Inverter vs High-Frequency Inverter

These inverters are mostly found in applications with high volume or weight needs, such as aerospace, mobile power supplies, electric vehicles, or other fields. Power Frequency

Get Price

High Frequency Inverter vs Low Frequency Inverter: How to choose

Discover the disparities between high frequency inverter vs low frequency inverter in this concise article, aiding your decision-making process.

Get Price

MIT Open Access Articles A High Frequency Inverter for

This paper presents a high-frequency inverter system that can directly drive widely-varying load impedances with high efficiency and fast dynamic response. Based on the architecture

Get Price

Design and Analysis of High Frequency Inverter for Induction

To facilitate high-frequency (HF) induction heating, a power electronic inverter has been specifically designed.

Get Price

What is the difference between a low frequency inverter and a

The primary distinctions between low-frequency inverters and high-frequency inverters lie in their operating frequencies, design structures, and performance characteristics

Get Price

Low Frequency VS High Frequency Inverter

Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for your solar system.

Get Price

Is it better to choose industrial frequency or high frequency inverter

High conversion efficiency: The high-frequency inverter has a high operating frequency, which reduces the switching loss in the circuit, thereby improving the overall

Get Price

The difference between industrial frequency inverter and high frequency

Because the high-frequency inverter adopts a small-sized and light-weight high-frequency magnetic core material, the power density of the circuit is greatly increased, so that

Get Price

Power Frequency Inverter vs High-Frequency Inverter

High-frequency inverters are typically more efficient at converting power while maintaining a constant load for lighter loads, which is significant when you depend on battery

Get Price

Understanding the Difference Between Frequency

Choosing between a frequency inverter and a high-frequency inverter depends on your specific needs—whether you''re looking for power

Get Price

What is the difference between a low frequency inverter and a high

Efficiency and Losses Low-Frequency Inverter: Due to the use of larger transformers, efficiency may not be as high as that of high-frequency inverters, especially

Get Price

Research on High-Frequency Isolated NPC Three

To tackle these challenges, this paper presents a three-stage topology for high-frequency isolated frequency conversion and speed

Get Price

High frequency inverter vs low frequency inverter

This article compares high frequency inverter vs low frequency inverter from the aspects of working frequency, components, efficiency, size

Get Price

High Vs Low Frequency Inverters/UPS Comparison

Let us compare High Vs Low-Frequency Inverters/UPS Comparison. Two kinds of commonly used Inverters/UPS; High Frequency and Low

Get Price

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

High-frequency inverters represent a more modern approach, engineered to overcome the size and weight limitations of their line-frequency counterparts. The topology is

Get Price

Frequency inverters

The tasks and function of a frequency inverter are varied depending on the model, for example the " frequency inverter 400v " or " frequency inverter 230v ", and

Get Price

Understanding the Difference Between Frequency Inverters and High

Choosing between a frequency inverter and a high-frequency inverter depends on your specific needs—whether you''re looking for power efficiency, space saving, or suitability for...

Get Price

The differences and similarities between high-frequency inverters

Efficiency: Since high-frequency inverters use high-frequency switches for inversion, their switching losses are relatively small, so they have higher conversion efficiency.

Get Price

Is it better to choose industrial frequency or high frequency

High conversion efficiency: The high-frequency inverter has a high operating frequency, which reduces the switching loss in the circuit, thereby improving the overall

Get Price

Surge vs. Efficiency: Choosing Between Low and High

High-frequency inverters represent a more modern approach, engineered to overcome the size and weight limitations of their line-frequency counterparts. The topology is

Get Price

The current status and development of DC/AC inverter technology

The traditional DC/AC inverter technology of the low-frequency link inverter process has been gradually replaced by the high-frequency band inverter process.

Get Price

Learn About High vs. Low Frequency Inverters: Which

An inverter is a key component that converts DC power into AC power for household appliances and is commonly used in solar energy

Get Price

What is the difference between a low frequency inverter and a high

The primary distinctions between low-frequency inverters and high-frequency inverters lie in their operating frequencies, design structures, and performance characteristics

Get Price

High frequency vs low frequency pure sine wave inverter

While for high-frequency inverter, their electronic parts such as the MOSFETs are directly subject to load power fluctuations. With fewer PCBs, low-frequency inverters are

Get Price

Design and Control of a High-Frequency, High-Efficiency Single

On the other hand, multiple-stage inverters accept a wide range of input voltage variations, but suffer from high cost, complicated structure and low efficiency.

Get Price

6 FAQs about [Conversion efficiency of industrial frequency inverter and high frequency inverter]

What is the difference between high frequency and industrial frequency inverter?

The same power inverter industrial frequency inverter is far heavier than the high-frequency inverter, high frequency inverter is small in size, light in weight, high in efficiency, low no-load load, but can’t be connected to a full inductive load, and overload capacity is poor.

Why are high frequency inverters more efficient?

In contrast, high-frequency inverters can use smaller-sized and lighter-weight components due to their use of higher frequencies, resulting in smaller overall size and weight. Efficiency: Since the high frequency inverter uses high-frequency switches for inversion, its switching loss is relatively small, so it has higher conversion efficiency.

How do high frequency power inverters convert DC to AC?

High frequency power inverters typically convert the DC to AC by driving the transistors at a much higher frequency from 50 Kilo Hz to a few million Hz. Low frequency inverter circuit diagram

What are frequency converters & inverters?

Frequency converters are used in hybrid technologies to combine conventional energy sources and stored energy for higher-level energy management. Inverters are also known by many other names: Variable speed drives, three-phase drives, variable speed drives, inverters, power converters and power converters.

Should you choose a low frequency or high frequency inverter?

For applications that require high power quality and are sensitive to the electromagnetic environment, you can choose an Low Frequency inverter; while for applications that require portability, high efficiency and fast response, High frequency inverters are more advantageous.

How does a low frequency inverter work?

The low frequency inverter first inverts the DC power into low-frequency low-voltage AC power, and then boosts it through the low frequency transformer into 220V, 50Hz AC power for the load. Features of low frequency inverter:

More related information

-

Is the grid-connected inverter industrial frequency or high frequency

Is the grid-connected inverter industrial frequency or high frequency

-

High frequency replaces industrial frequency inverter

High frequency replaces industrial frequency inverter

-

High frequency inverter frequency

High frequency inverter frequency

-

High frequency inverter is also a sine wave

High frequency inverter is also a sine wave

-

The frequency on the high-voltage side of the inverter is too high

The frequency on the high-voltage side of the inverter is too high

-

Inverter high frequency modulation

Inverter high frequency modulation

-

Silicon Carbide High Frequency Inverter

Silicon Carbide High Frequency Inverter

-

Price of high frequency inverter front stage

Price of high frequency inverter front stage

Commercial & Industrial Solar Storage Market Growth

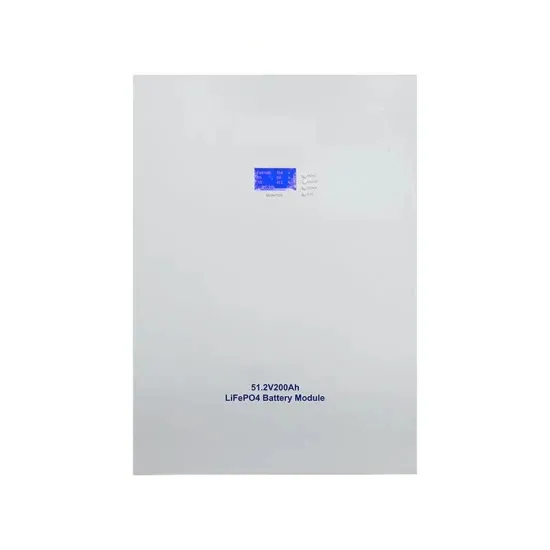

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.