What Affects the Cost of Custom Lithium Battery Packs?

The truth is, the cost of a custom lithium battery pack is shaped by multiple technical and application-specific factors. Understanding these drivers can help you make

Get Price

Pack

A pack is a container of something, especially one made of sturdy paper. You might run to the store for a pack of batteries for your new clock and a pack of crayons for your new coloring book.

Get Price

Lithium-Ion Battery Manufacturing Plant: Setup & Cost

The lithium-ion battery manufacturing plant report provides detailed insights into project economics, cost breakdown, setup requirements & ROI etc.

Get Price

Battery Manufacturing Plant Report 2025: Setup and Cost

The battery manufacturing plant report provides detailed insights into project economics, cost breakdown, setup requirements & ROI etc.

Get Price

pack

pack (third-person singular simple present packs, present participle packing, simple past and past participle packed) (physical) To put or bring things together in a limited or

Get Price

What Determines Custom Battery Pack Manufacturing Prices?

Most manufacturers require 500-1,000 units for economical production. Some accept 100-unit orders at 60-80% cost premium. Prototype services typically offer 10-50 units

Get Price

Lithium-Ion Battery Production Cost Analysis | Case Study

Case Study on Lithium-Ion Battery Production Cost: A comprehensive financial model for the plant''s setup, manufacturing, machinery and operations.

Get Price

How To Set Up A Lithium-Ion Battery Manufacturing Plant In India

Includes free support Lithium-Ion Battery Learn how to establish a Lithium-ion battery manufacturing facility in India. Explore the process, requirements, and opportunities for setting

Get Price

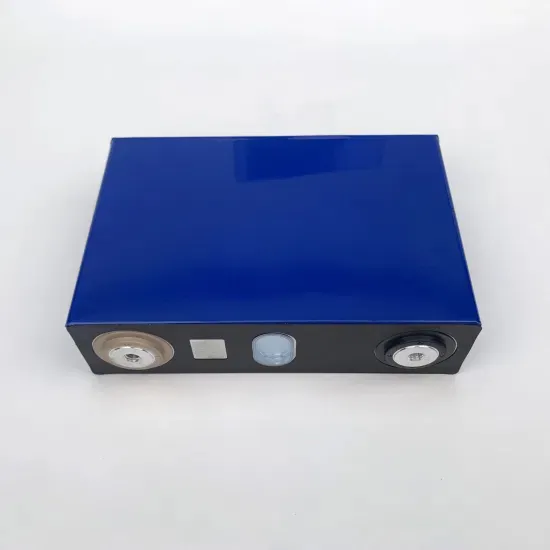

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent

Get Price

A Techno-Economic Model for Benchmarking the

Thus, developing a cost model that simultaneously includes the physical and chemical characteristics of battery cells, commodities prices, process

Get Price

Lithium-Ion Battery Costs: Manufacturing Prices, Components,

Prices depend on battery chemistry, like LFP or NMC, and geography, such as China or the West. For electric vehicle packs, costs range from $7,000 to $20,000. In mass

Get Price

Custom Battery Pack Manufacturing & Energy

48V Solar Battery 72V Golf Cart Battery Precision-Crafted Lithium Ion Battery Solutions As a certified OEM/ODM lithium battery pack specialist since 2007,

Get Price

Tutorial : How To Make LITHIUM BATTERY PACKS Best Money

In this video I will be explaining you, How to Make Lithium Battery Packs which is now one of the best money making methods in the game as one unit sells for...

Get Price

Leading Battery Pack Manufacturers in China: A 2025

Fun Fact: Lishen has been a pioneer in the battery industry for over two decades, consistently pushing the boundaries of what''s possible with

Get Price

Lithium Battery Packs | BigBattery | Your Source for

"Big Battery made converting our 48v lead acid EZGO cart to lithium a breeze. Our cart is lighter, faster and the range went up dramatically using just a single

Get Price

Start Lithium Ion Battery Manufacturing: Costs & Steps to Succeed

When it comes to constructing a factory for lithium-ion battery production, businesses can expect to spend anywhere from $500,000 to $2,000,000 on the overall

Get Price

Start Lithium Ion Battery Manufacturing: Costs

When it comes to constructing a factory for lithium-ion battery production, businesses can expect to spend anywhere from $500,000 to

Get Price

PACK Definition & Meaning | Dictionary

a group of things wrapped or tied together for easy handling or carrying; a bundle, especially one to be carried on the back of an animal or a person: a hiker''s pack.

Get Price

Start Lithium Ion Battery Manufacturing: Costs & Steps to Succeed

The cost of constructing a factory for lithium-ion battery manufacturing is influenced by several key factors. The location of the factory, quality of materials, size of the facility, and

Get Price

Custom Lithium Battery Pack Manufacturing

Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering

Get Price

How To Estimate The Costs To Start A Lithium Battery Factory

Find out the startup costs of establishing a lithium-ion battery factory. Our detailed guide covers all the necessary expenses.

Get Price

How Much Does It Cost to Start a Lithium Ion Battery

In conclusion, starting a lithium ion battery manufacturing business involves understanding various costs and strategic planning. By analyzing manufacturing costs, supply chain

Get Price

pack verb

Definition of pack verb in Oxford Advanced Learner''s Dictionary. Meaning, pronunciation, picture, example sentences, grammar, usage notes, synonyms and more.

Get Price

Lithium ion battery materials?

Over the past ten years, the cost of input materials has risen at a 3% pa CAGR. The chart below shows the material costs of lithium ion batteries compared with the total cost of battery packs,

Get Price

What Are the 2025 Startup Costs for Lithium Ion Battery

Earnings for lithium ion battery manufacturing owners can vary widely depending on several factors, including the scale of operations, market demand for batteries, and overall

Get Price

Lithium Ion Battery Manufacturing: Cost Breakdown

Ever wondered about the Lithium Ion Battery Manufacturing Cost when launching your battery factory? Do fixed costs, raw material prices, and

Get Price

pack

a definite quantity or standard measure of something wrapped up or otherwise assembled for merchandising (sometimes used in combination): a pack of cigarettes; a six-pack of beer.

Get Price

How To Estimate The Costs To Start A Lithium

Find out the startup costs of establishing a lithium-ion battery factory. Our detailed guide covers all the necessary expenses.

Get Price

Lithium ion battery materials?

Over the past ten years, the cost of input materials has risen at a 3% pa CAGR. The chart below shows the material costs of lithium ion batteries compared

Get Price

6 FAQs about [Pack lithium battery factory cost]

How much does a lithium ion battery cost?

Lithium ion battery costs range from $40-140/kWh, depending on the chemistry (LFP vs NMC), geography (China vs the West) and cost basis (cash cost, marginal cost and actual pricing). This data-file is a breakdown of lithium ion battery costs, across c15 materials and c20 manufacturing stages, so input assumptions can be stress-tested.

Is lithium ion battery manufacturing a good investment?

This surge presents an incredible opportunity for entrepreneurs looking to dive into the battery manufacturing industry. Lithium Ion Battery Manufacturing Costs can be a significant barrier to entry, but understanding these costs can set you on the right path to success.

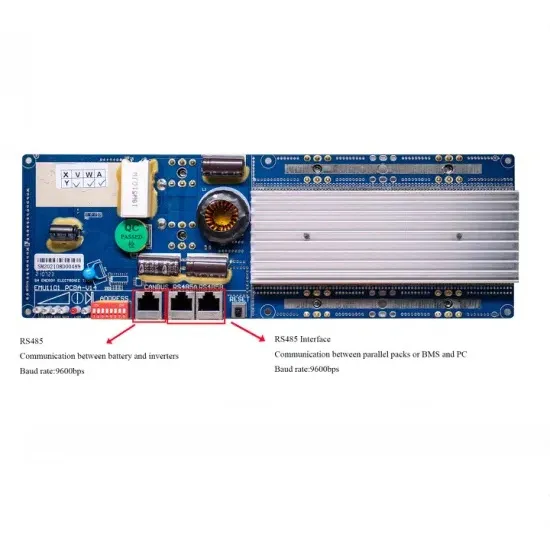

What makes a custom lithium-ion battery pack unique?

The foundation of any custom lithium-ion battery pack lies in the selection of the integrated cells. Our cell selection for custom packs involves: Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities.

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

What is a lithium-ion battery manufacturing plant?

A lithium-ion battery manufacturing plant is a facility designed for the large-scale production of rechargeable battery cells used in various modern technologies. These plants carry out a series of precision-driven processes, including electrode preparation, cell assembly, electrolyte filling, formation, and quality testing.

How are materials costs of lithium ion batteries calculated?

The breakdown covers 25 categories (e.g., lithium, nickel, graphite), across 10 different battery chemistries (e.g., NCA, NMC, LFP and others, chart below). Materials costs of lithium ion batteries can be calculated by comparing our mass balances above with the costs of different input commodity prices.

More related information

-

Qatar good lithium battery pack factory price

Qatar good lithium battery pack factory price

-

Botswana regular lithium battery pack factory price

Botswana regular lithium battery pack factory price

-

San Marino 32650 lithium battery pack factory

San Marino 32650 lithium battery pack factory

-

Bolivia pack lithium battery factory

Bolivia pack lithium battery factory

-

Southern Europe Pack Lithium Battery Factory

Southern Europe Pack Lithium Battery Factory

-

How much does a lithium battery pack cost in Algeria

How much does a lithium battery pack cost in Algeria

-

New lithium iron phosphate battery pack factory in St Lucia

New lithium iron phosphate battery pack factory in St Lucia

-

How much does an Austrian lithium battery pack cost

How much does an Austrian lithium battery pack cost

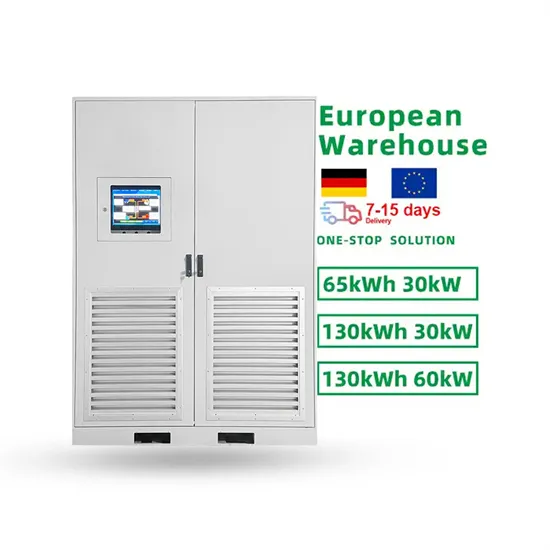

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.