The difference between monocrystalline silicon and polycrystalline

Overall, monocrystalline silicon is suitable for high demand electronic and semiconductor fields, while polycrystalline silicon is more suitable for solar cells and certain

Get Price

What is the difference between monocrystalline and polycrystalline PV

Monocrystalline silicon modules are more expensive but more efficient, while polycrystalline modules are cheaper, suitable for projects with limited budgets.

Get Price

Monocrystalline vs. Polycrystalline Solar Panels –

Unsure about the differences between difference between monocrystalline vs polycrystalline solar panels? Learn the pros and cons of

Get Price

Degradation analysis of polycrystalline silicon modules from

Carr and Pryor [24] evaluated the degradation of five dissimilar PV module technologies produced by seven manufacturers installed in Perth, Australia for a period of 16

Get Price

Monocrystalline vs Polycrystalline Solar Panels

Understanding monocrystalline vs. polycrystalline and recent innovations that have led many to ask which PV type is better.

Get Price

Monocrystalline vs. Polycrystalline

Understanding monocrystalline vs. polycrystalline and recent innovations that have led many to ask which PV type is better.

Get Price

Performance comparison of monocrystalline and polycrystalline

How does the operating temperature of photovoltaic modules affect the performance efficiency of monocrystalline and polycrystalline modules in high latitudes before

Get Price

What Is a Monocrystalline Solar Panel? Definition,

The higher cost of monocrystalline panels is attributed to their complex manufacturing process and the use of high-purity silicon, which

Get Price

Comparative analysis on photovoltaic thermal (PVT) system using

This work summarizes and compares various PVT systems from various sources, both air-based and water-based, and then categorizes the sample into two major modules:

Get Price

Solar panel types and differences: monocrystalline

The main types of solar panels on the market today are monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Differences between

Get Price

Solar panel types and differences: monocrystalline silicon

The main types of solar panels on the market today are monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Differences between monocrystalline, polycrystalline

Get Price

Monocrystalline vs. Polycrystalline: The Hidden Structure Behind

3 days ago· Monocrystalline Solar Panels Because the silicon in a monocrystalline cell is a single, perfect crystal, electrons have a clear, unobstructed path to travel. This lack of grain

Get Price

Monocrystalline vs Polycrystalline Solar Panels:

In comparing monocrystalline and polycrystalline solar panels, several key differences emerge that can guide your selection. Monocrystalline

Get Price

Monocrystalline vs. Polycrystalline Solar Cells

Owing to differences in material properties, expense of manufacturing, and energy efficiency, both materials have distinct advantages and disadvantages

Get Price

Monocrystalline vs Polycrystalline Solar Panels: Which

In comparing monocrystalline and polycrystalline solar panels, several key differences emerge that can guide your selection. Monocrystalline panels consistently

Get Price

Monocrystalline vs. Polycrystalline Solar Cells

Owing to differences in material properties, expense of manufacturing, and energy efficiency, both materials have distinct advantages and disadvantages that guide decision-making in solar

Get Price

What are monocrystalline, polycrystalline and thin film

Basic introduction into solar panel and cell technology. Monocrystalline, polycrystalline and thin film solar panels and how to indentify

Get Price

Monocrystalline vs. Polycrystalline solar panels

The two main types of silicon solar panels are monocrystalline and polycrystalline. Learn their differences and compare mono vs poly solar.

Get Price

Monocrystalline vs. Polycrystalline: Which One Is the

Monocrystalline vs. Polycrystalline: How Are They Made? How Is a Mono Solar Panel Made? Monocrystalline solar panels are premium solar

Get Price

Monocrystalline vs Polycrystalline Solar Panels

In this article, we will do a full in-depth comparison between Monocrystalline and Polycrystalline solar panels including: How are they made? What do they look like? How

Get Price

Crystalline Silicon Module

Polycrystalline silicon (poly c-Si): The next type of c-Si PV module is the poly c-Si, whose market is a bit lower when compared to mono c-Si. The problem of metal contamination exists in

Get Price

Monocrystalline VS Polycrystalline Solar PV Modules

Listed below is the main disadvantage of the Monocrystalline solar panels: Cost Ineffective Solar panels with monocrystalline crystals are more

Get Price

Monocrystalline vs Polycrystalline (Multicrystalline):

A solar panel, often referred to as a photovoltaic (PV) panel or module, is a device that converts sunlight into electricity. There are two main

Get Price

Monocrystalline vs. Polycrystalline Silicon: Which Solar Cell Is

Two of the most common types of solar cells available today are monocrystalline and polycrystalline silicon cells. Each type has distinct characteristics, benefits, and

Get Price

What is the difference between monocrystalline and

Monocrystalline silicon modules are more expensive but more efficient, while polycrystalline modules are cheaper, suitable for projects with limited budgets.

Get Price

The Difference Between Monocrystalline Silicon and Polycrystalline

7. The price/performance ratio At present, the price-performance ratio of polycrystalline solar panels is slightly higher than that of monocrystalline silicon solar panels, but it is only for now.

Get Price

Monocrystalline Solar Panels: Advantages and

Each module is made from a single silicon crystal, and is more efficient, though more expensive, than the newer and cheaper polycrystalline and thin-film PV

Get Price

Types of photovoltaic solar panels and their

Polycrystalline panels, on the other hand, are made from multiple silicon crystals fused together. This production method is simpler and less

Get Price

6 FAQs about [Monocrystalline silicon and polycrystalline silicon in photovoltaic modules]

What is a monocrystalline solar panel?

Monocrystalline solar panels have black-colored solar cells made of a single silicon crystal and usually have a higher efficiency rating. However, these panels often come at a higher price. Polycrystalline solar panels have blue-colored cells made of multiple silicon crystals melted together.

How are monocrystalline solar panels made?

Each monocrystalline solar panel is made of 32 to 96 pure crystal wafers assembled in rows and columns. The number of cells in each panel determines the total power output of the cell. How are Polycrystalline Solar Panels Made? Polycrystalline also known as multi-crystalline or many-crystal solar panels are also made from pure silicon.

Are monocrystalline solar panels expensive?

Among all types of PV solar panels types, monocrystalline is definitely the most expensive one to produce. This is due to the fact that the process of manufacturing monocrystalline solar cells is very energy-intensive and produces a big amount of silicon waste. How Expensive are Polycrystalline Solar Panels?

What is a polycrystalline solar cell?

Polycrystalline solar cells are also called "multi-crystalline" or many-crystal silicon. Polycrystalline solar panels generally have lower efficiencies than monocrystalline cell options because there are many more crystals in each cell, meaning less freedom for the electrons to move.

What are the advantages and disadvantages of monocrystalline silicon solar cells?

Advantages: 1. High conversion efficiency: Monocrystalline silicon solar cells have high photoelectric conversion efficiency, which can better convert solar energy into electrical energy. 2. Low photoelectric conversion loss: Compared with polycrystalline silicon, monocrystalline silicon has lower photoelectric conversion loss.

What is the difference between monocrystalline and polycrystalline PV cells?

Although monocrystalline have higher efficiency rates, the difference between mono and polycrystalline cells isn’t that big. Most polycrystalline PV cells have efficiencies between 13% to 16%, which is still a very good ratio and it’s expected to get only higher in the future. D. Mono-Si vs Poly-Si Temperature Coefficient?

More related information

-

Price of photovoltaic modules monocrystalline and polycrystalline

Price of photovoltaic modules monocrystalline and polycrystalline

-

Polycrystalline silicon double-glass photovoltaic modules

Polycrystalline silicon double-glass photovoltaic modules

-

Monocrystalline silicon lightweight flexible photovoltaic modules

Monocrystalline silicon lightweight flexible photovoltaic modules

-

Monocrystalline silicon and polycrystalline silicon photovoltaic panel installation

Monocrystalline silicon and polycrystalline silicon photovoltaic panel installation

-

What is monocrystalline silicon in photovoltaic modules

What is monocrystalline silicon in photovoltaic modules

-

Georgia monocrystalline silicon photovoltaic panels

Georgia monocrystalline silicon photovoltaic panels

-

Parallel connection of monocrystalline silicon photovoltaic panels

Parallel connection of monocrystalline silicon photovoltaic panels

-

The best quality monocrystalline silicon photovoltaic panels

The best quality monocrystalline silicon photovoltaic panels

Commercial & Industrial Solar Storage Market Growth

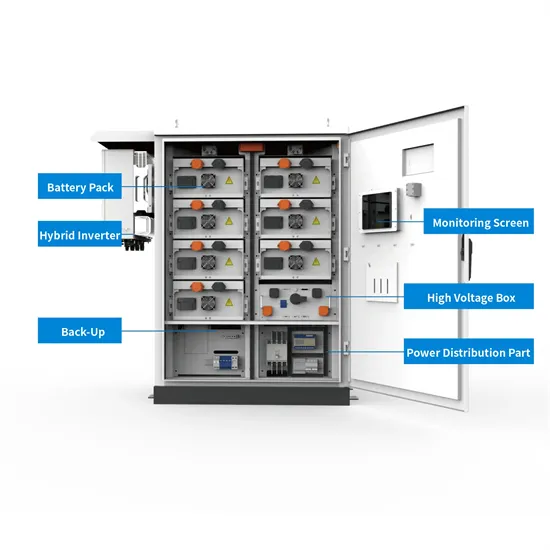

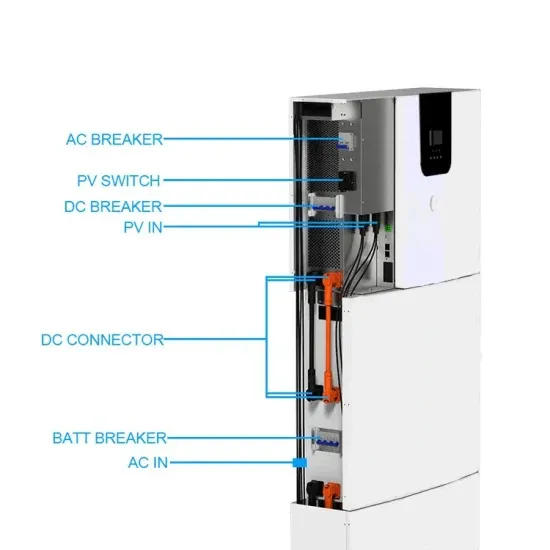

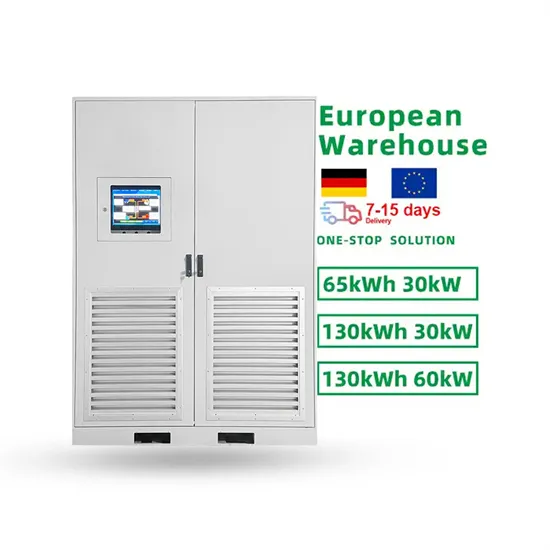

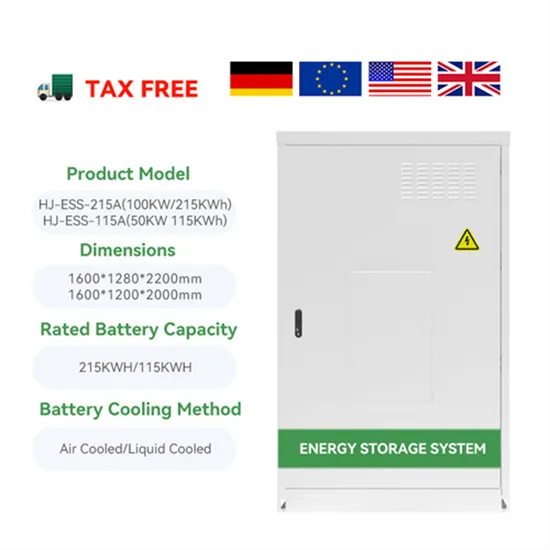

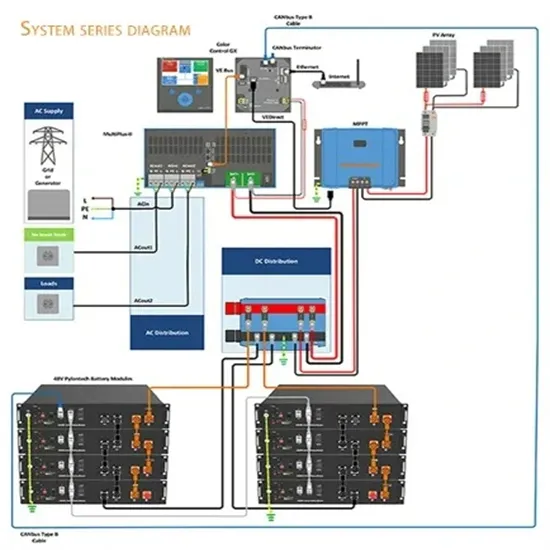

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

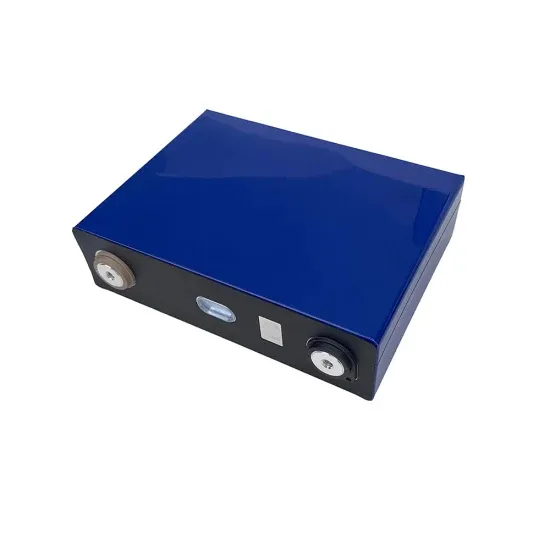

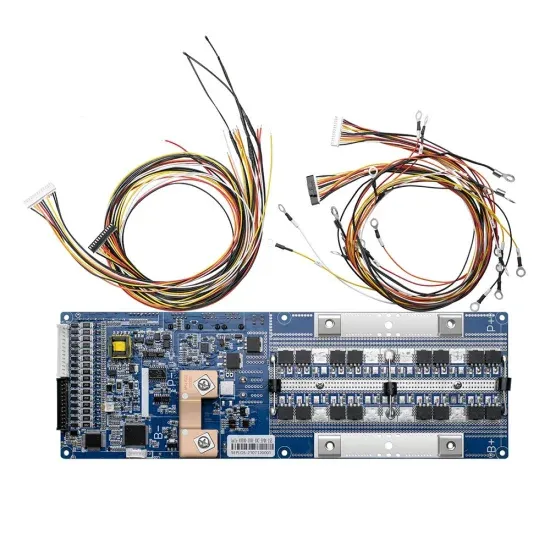

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.