Monocrystalline solar panels: the expert guide [2025]

Here are what monocrystalline solar panels are, how they''re made, and why they''re better than other panel types.

Get Price

What is Monocrystalline Solar Panel: A Consolidated Guide

Monocrystalline panels have a larger surface area due to the pyramid cell pattern. This enables them to gather more energy from the sun. As they are made without any mixed

Get Price

Monocrystalline Solar Panels: Advantages and Disadvantages

Each module is made from a single silicon crystal, and is more efficient, though more expensive, than the newer and cheaper polycrystalline and thin-film PV panel technologies. You can

Get Price

GA: ESA Renewables Commissions Georgia''s Largest Ground

Based in metro-Atlanta, GA, Suniva® manufactures high-efficiency monocrystalline silicon solar cells and high-power solar modules using patented low-cost techniques.

Get Price

Made-In-The-USA Monocrystalline Solar Cells: Not A Dream

Despite its red-state reputation on climate action, Georgia will host the nation''s only domestic manufacturer of monocrystalline solar cells.

Get Price

The 6 types of solar panels | What''s the best type?

Discover the six main types of solar panel, including thin-film, perovskite, and the best type for your home: monocrystalline.

Get Price

Monocrystalline Solar Panels: 2025 Costs & How They Work

Made from a single crystal of pure silicon, these panels convert sunlight into electricity with industry-leading performance. They''re sleek, durable, and perfect for

Get Price

PV spot price

InfoLink Consulting provides weekly updates on PV spot prices, covering module price, cell price, wafer price, and polysilicon price. Learn about photovoltaic panel price trends

Get Price

The first entirely US-made crystalline solar panels are

All US-made solar panels featured only imported solar cells until now, but two US manufacturers just struck a three-year, $400 million deal.

Get Price

SunPower Solar Panels | Solar Products | SunPower Global

SunPower Maxeon solar panels are the highest efficiency panel you can buy with unmatched reliability * Jordan, et. al. Robust PV Degradation Methodology and Application. PVSC 2018.

Get Price

Monocrystalline silicon solar cells applied in photovoltaic system

Purpose: The aim of the paper is to fabricate the monocrystalline silicon solar cells using the conventional technology by means of screen printing process and to make of them

Get Price

End-of-Life Solar Panels: Regulations and Management

CdTe is the second-most common PV material after silicon, and cells can be made using low-cost manufacturing processes, but their

Get Price

Monocrystalline solar panels – Uses, Benefits and Drawbacks

What Makes Monocrystalline Solar Panels Unique From Others? The manufacturing method and effectiveness of monocrystalline solar panels vary from those of

Get Price

Suniva Upgrades Manufacturing and Restarts Operations in Georgia

Norcross, Ga. – October 11, 2023 – Suniva, Inc., the largest U.S. manufacturer of high-efficiency monocrystalline silicon solar cells today announced the upgrade, expansion and restart of

Get Price

Georgia Power receives approval from Georgia PSC for five new

Georgia Power this week received approval from the Georgia Public Service Commission to certify five new utility-scale solar site power purchase agreements.

Get Price

The first entirely US-made crystalline solar panels are

All US-made solar panels featured only imported solar cells until now, but two US manufacturers just struck a three-year, $400 million deal.

Get Price

Monocrystalline Solar Panels: How They Work, Pros

Monocrystalline solar panels utilize monocrystalline silicon cells to transform sunlight into usable electrical energy. These cells are made from

Get Price

HS Code 85414300

Photovoltaic cells assembled in modules or made up into panels; Examples: - Photovoltaic cells assembled in modules (500 watts, 1200mm x 600mm x 40mm)

Get Price

Corning, Suniva and Heliene Announce First ''Made in

Both the wafers and polysilicon are made in Michigan, and the solar cells are made in Georgia, ensuring American-made solar components of the

Get Price

What is Monocrystalline Solar Panel: A Consolidated

Monocrystalline panels have a larger surface area due to the pyramid cell pattern. This enables them to gather more energy from the sun.

Get Price

Monocrystalline Solar Panel Efficiency, Construction

Additionally, the purity of the silicon used in these panels is crucial. High-purity silicon reduces electron recombination, which is a loss mechanism

Get Price

Corning, Suniva and Heliene Announce First ''Made in America''

Both the wafers and polysilicon are made in Michigan, and the solar cells are made in Georgia, ensuring American-made solar components of the highest quality form the

Get Price

Monocrystalline vs. Polycrystalline solar panels

The two main types of silicon solar panels are monocrystalline and polycrystalline. Learn their differences and compare mono vs poly solar.

Get Price

Status and perspectives of crystalline silicon photovoltaics in

Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Get Price

Monocrystalline Solar Panels: Advantages and

Each module is made from a single silicon crystal, and is more efficient, though more expensive, than the newer and cheaper polycrystalline and thin-film PV

Get Price

What is Monocrystalline Solar Panel? Advantages and

A monocrystalline solar panel is a solar panel comprising monocrystalline solar cells. The panel derives its name from a cylindrical silicon ingot grown from single-crystal

Get Price

GA: ESA Renewables Commissions Georgia''s Largest Ground

ESA Renewables, LLC, a leading turnkey solar photovoltaic (PV) system provider, and Suniva, Inc., a U.S. manufacturer of high-efficiency monocrystalline silicon solar cells and

Get Price

Monocrystalline Solar Panels: 2025 Costs & How

Made from a single crystal of pure silicon, these panels convert sunlight into electricity with industry-leading performance. They''re sleek,

Get Price

How to Distinguish Mono, Poly and Amorphous Silicon Solar Panels?

Distinguishing between monocrystalline silicon, polycrystalline silicon, and amorphous silicon solar panels can be done by examining their physical appearance and

Get Price

6 FAQs about [Georgia monocrystalline silicon photovoltaic panels]

What is a monocrystalline solar panel?

They are made from monocrystalline solar cells formed from a single piece of silicon. This gives an easy path for electricity to pass through them. The cylindrical silicon ingot generated from high-quality single-crystal silicon is the reason behind its name. Monocrystalline panels have a larger surface area due to the pyramid cell pattern.

How are monocrystalline solar panels made?

Monocrystalline panels begin with a pure silicon seed crystal grown using the Czochralski method. This seed is slowly pulled from molten silicon, forming a single crystal ingot. The ingot is then sliced into thin wafers and treated with anti-reflective coatings and metal contacts to form solar cells.

How many solar cells are in a single monocrystalline panel?

Based on their size, a single monocrystalline panel may contain 60-72 solar cells, among which the most commonly used residential panel is a 60-cells. Features A larger surface area due to their pyramid pattern. The top surface of monocrystalline panels is diffused with phosphorus, which creates an electrically negative orientation.

Should you switch to monocrystalline solar panels?

Additionally, they reported instances where home owners have had to rip up all their thin film panels and sell those at a loss in order to boost the size of their solar power system when they switched over to monocrystalline solar cells to produce more electricity as their usage increased over the years.

Do monocrystalline solar panels reduce output?

Like other types of solar panels, monocrystalline solar modules suffer a reduction in output once the temperature from the sunlight reaches around fifty degrees Celsius/a hundred and fifteen degrees Fahrenheit. Reductions of between twelve and fifteen percent can be expected.

How much does a monocrystalline solar panel cost?

A single monocrystalline panel typically costs between $350 and $525 for a 350-watt unit. Pricing varies by manufacturer, efficiency rating, and technology tier. While these panels carry a higher price tag than other types, their performance and longevity often justify the investment.

More related information

-

Connection of monocrystalline silicon photovoltaic panels

Connection of monocrystalline silicon photovoltaic panels

-

Comparison of monocrystalline silicon and thin film photovoltaic panels

Comparison of monocrystalline silicon and thin film photovoltaic panels

-

Are monocrystalline silicon photovoltaic panels afraid of corrosion

Are monocrystalline silicon photovoltaic panels afraid of corrosion

-

The best quality monocrystalline silicon photovoltaic panels

The best quality monocrystalline silicon photovoltaic panels

-

Monocrystalline silicon on solar photovoltaic panels

Monocrystalline silicon on solar photovoltaic panels

-

Photovoltaic monocrystalline silicon solar panels

Photovoltaic monocrystalline silicon solar panels

-

Photovoltaic power generation production of monocrystalline silicon panels

Photovoltaic power generation production of monocrystalline silicon panels

-

Making monocrystalline silicon photovoltaic panels

Making monocrystalline silicon photovoltaic panels

Commercial & Industrial Solar Storage Market Growth

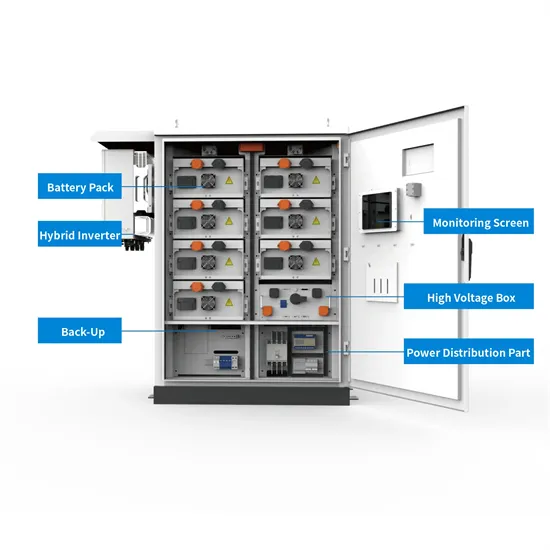

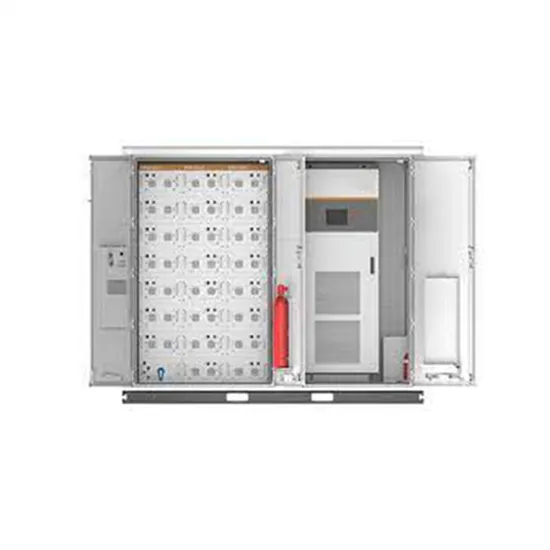

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

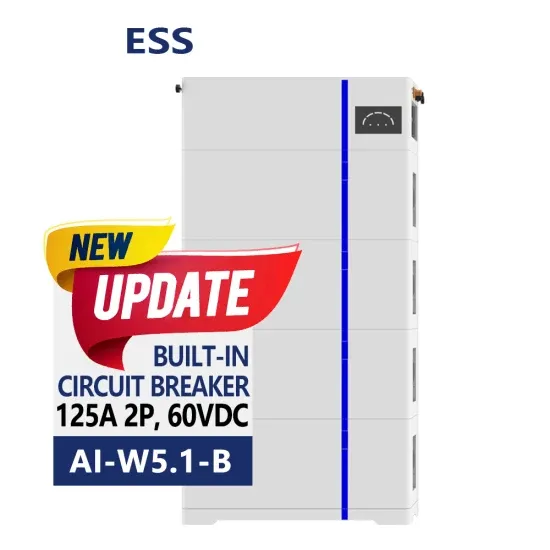

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.