Monocrystalline Solar Panels: Advantages and

8 Good Reasons Why Monocrystalline Solar Panels are the Industry Standard Monocrystalline photovoltaic electric solar energy panels have been the go-to

Get Price

5 Steps For Monocrystalline Silicon Solar Cell Production

Turning silicon ingots into solar wafers is a high-precision, high-wasteoperation where up to 40% of the silicon is lostas kerf (sawdust). The industry standard is diamond wire

Get Price

How to make photovoltaic panels with monocrystalline silicon

This article will provide an overview of how monocrystalline solar panels work, their installation requirements, practical applications, and tips for selecting the best solar panel

Get Price

Maximizing Efficiency: The Advantages of

When choosing panels, consider the efficiency ratings, installation needs, and balance the cost against performance benefits. Understanding

Get Price

Types of photovoltaic solar panels and their characteristics

Photovoltaic solar panels are devices specifically designed for the generation of clean energy from sunlight. In general, photovoltaic panels are classified into three main

Get Price

Beyond 30% Conversion Efficiency in Silicon Solar Cells: A

We demonstrate through precise numerical simulations the possibility of flexible, thin-film solar cells, consisting of crystalline silicon, to achieve power conversion efficiency of

Get Price

What Are Solar Panels Made Of and How Are They

Answering that question means understanding how solar energy works, how solar panels are manufactured, and what the parts of a solar panel

Get Price

Learn How to Make a Monocrystalline Solar Cell Easily

Learn how to make a monocrystalline solar cell with this easy-to-follow guide that covers the entire process, from silicon wafer preparation to

Get Price

How to make monocrystalline solar cells?

Monocrystalline solar cells are made from a single, high-purity silicon crystal. The manufacturing process for making monocrystalline solar

Get Price

Monocrystalline Solar Panel Efficiency, Construction

Understanding the construction of monocrystalline solar panels is key to appreciating their efficiency. These panels are crafted from high-quality

Get Price

Monocrystalline solar panels: the expert guide [2025]

These solar panels are made with extremely pure polysilicon, which is created by melting nuggets of quartzite at around 1,700°C, then refining it by

Get Price

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get Price

What Are Solar Panels Made Of and How Are They

Solar panels are made of monocrystalline or polycrystalline silicon solar cells soldered together and sealed under an anti-reflective glass cover.

Get Price

How to make solar panels from monocrystalline silicon

In summation, the journey of creating monocrystalline silicon solar panels is a detailed and intricate process, encompassing numerous steps that ensure high efficiency and

Get Price

Monocrystalline Silicon

20.3.1.1 Monocrystalline silicon cells Monocrystalline silicon is the most common and efficient silicon-based material employed in photovoltaic cell production. This element is often referred

Get Price

Monocrystalline Solar Panel Efficiency, Construction & Functionality

Understanding the construction of monocrystalline solar panels is key to appreciating their efficiency. These panels are crafted from high-quality silicon, which is a

Get Price

How to make monocrystalline solar cells?

Monocrystalline solar cells are made from a single, high-purity silicon crystal. The manufacturing process for making monocrystalline solar cells is complex and time-consuming.

Get Price

Learn How to Make a Monocrystalline Solar Cell Easily

Learn how to make a monocrystalline solar cell with this easy-to-follow guide that covers the entire process, from silicon wafer preparation to cell assembly.

Get Price

What are polycrystalline solar panels?

Monocrystalline vs polycrystalline panels Monocrystalline solar panels are the higher-end alternative to polycrystalline panels. These panels are made from a single piece of

Get Price

What are monocrystalline solar panels?

What are monocrystalline solar panels? Monocrystalline solar panels are a type of solar panel design that uses a single silicon crystal to capture sunlight and generate energy.

Get Price

Monocrystalline solar panels: the expert guide [2025]

These solar panels are made with extremely pure polysilicon, which is created by melting nuggets of quartzite at around 1,700°C, then refining it by using the Siemens process.

Get Price

What Are Solar Panels Made Of and How Are They Made?

Solar panels are made of monocrystalline or polycrystalline silicon solar cells soldered together and sealed under an anti-reflective glass cover. The photovoltaic effect

Get Price

Solar Photovoltaic Manufacturing Basics

Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing steps that

Get Price

Solar Photovoltaic Manufacturing Basics

Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing steps that typically occur separately from each other.

Get Price

Solar Manufacturing Cost Analysis | Solar Market

Solar Manufacturing Cost Analysis NREL analyzes manufacturing costs associated with photovoltaic (PV) cell and module technologies and

Get Price

Monocrystalline vs Amorphous Solar Panels: A

Amorphous solar panels operate similarly to their monocrystalline counterparts, by using the photovoltaic effect. However, the key difference

Get Price

Perovskite Solar Cells: An In-Depth Guide

An in-depth guide to perovskite solar cells: materials, structure, benefits, challenges, and comparisons with c-Si and thin-film solar cells.

Get Price

Monocrystalline silicon: efficiency and manufacturing process

Monocrystalline silicon is the base material for silicon chips used in virtually all electronic equipment today. In the field of solar energy, monocrystalline silicon is also used to

Get Price

Monocrystalline silicon: efficiency and manufacturing

Monocrystalline silicon is the base material for silicon chips used in virtually all electronic equipment today. In the field of solar energy,

Get Price

What Are Solar Panels Made Of? Detailed Materials

Key Insights The main materials used in solar panels, including silicon solar cells, tempered glass, and metal frames. How monocrystalline

Get Price

More related information

-

Georgia monocrystalline silicon photovoltaic panels

Georgia monocrystalline silicon photovoltaic panels

-

Are monocrystalline silicon photovoltaic panels afraid of corrosion

Are monocrystalline silicon photovoltaic panels afraid of corrosion

-

Size and weight of monocrystalline silicon photovoltaic panels

Size and weight of monocrystalline silicon photovoltaic panels

-

Parallel connection of monocrystalline silicon photovoltaic panels

Parallel connection of monocrystalline silicon photovoltaic panels

-

Connection of monocrystalline silicon photovoltaic panels

Connection of monocrystalline silicon photovoltaic panels

-

The best quality monocrystalline silicon photovoltaic panels

The best quality monocrystalline silicon photovoltaic panels

-

Photovoltaic monocrystalline silicon solar panels

Photovoltaic monocrystalline silicon solar panels

-

Are single-glass double-sided photovoltaic panels monocrystalline silicon panels

Are single-glass double-sided photovoltaic panels monocrystalline silicon panels

Commercial & Industrial Solar Storage Market Growth

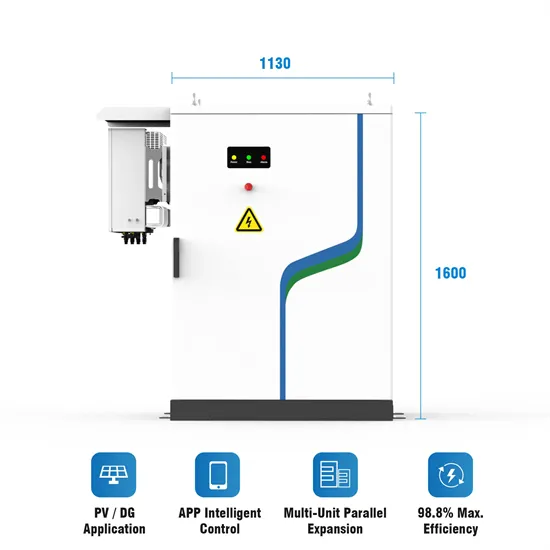

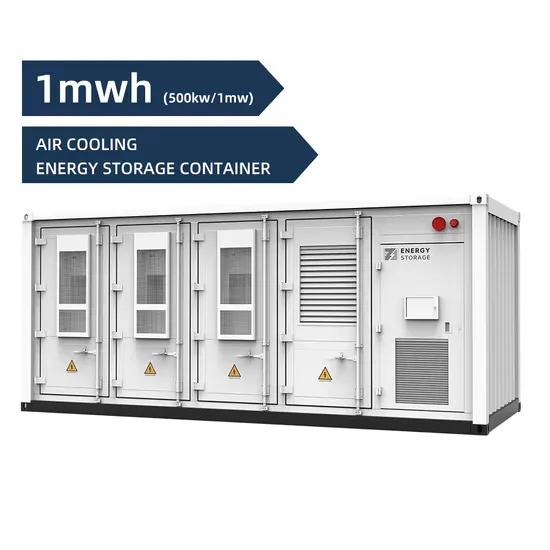

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.