The Environmental Impact of Solar Panel Production

Solar panel manufacturing involves multiple steps, including wafer production, cell fabrication, and module assembly. Each step requires energy and emits greenhouse gases.

Get Price

U.S. energy facts explained

U.S. energy production has been greater than U.S. energy consumption in recent years U.S. total annual energy production has exceeded total annual energy consumption

Get Price

Analyzing the lifecycle of solar panels manufacturing, and

Primary data will be procured from information regarding the extraction of raw materials, energy consumption metrics, and waste production, which will be sourced from solar panel

Get Price

Solar Panel Manufacturing''s Environmental Impact:

Manufacturing crystalline silicon cells involves multiple energy-intensive steps, including ingot formation, wafer slicing, and metal contact

Get Price

Returning solar panel production to US can ease climate

The scientists analyzed production in the U.S. to learn how it could shrink greenhouse gas emissions and energy use. If solar panel manufacturing can return to the U.S. by 2035, the

Get Price

Carbon Footprint of Solar Panel Manufacturing

PV panels have a nearly non-existent carbon footprint, around 40 grams per kWh of electrical energy produced. This only comes from the manufacturing process of making,

Get Price

What Is the Carbon Footprint of Solar Panel Production? A

Research suggests emissions for solar panel production range between 20-200 grams of CO2 per kilowatt-hour generated, depending on technology and location. Compared to fossil fuels,

Get Price

Returning solar panel production to US speeds decarbonization

The scientists found that if solar panel manufacturing can return to the U.S. by 2035, the greenhouse gas emissions resulting from panel creation would be reduced by 30% and energy

Get Price

Investigation of life cycle CO2 emissions of the polycrystalline and

Besides, the average energy payback period of the polycrystalline panel is 0.92 years, while it is 0.57 years for the CdTe panel. In addition, the emission amount of the solar

Get Price

Solar Panel Manufacturing''s Environmental Impact: The Truth

Manufacturing crystalline silicon cells involves multiple energy-intensive steps, including ingot formation, wafer slicing, and metal contact application. The silicon purification

Get Price

California State Energy Profile

California is the second-largest total energy consumer among the states, after Texas, but its per capita energy consumption is the third-lowest in the nation. In 2024,

Get Price

Carbon Footprint of Solar Panel Manufacturing

Carbon Footprint of Solar Panel Manufacturing: About 0.66kg silicon is used to manufacture a PV panel realising about 6.0kg of CO2e per kilo.

Get Price

Solar Panel Water Usage: The Truth About Manufacturing Impact

As concerns about the environmental cost of solar manufacturing grow, it''s crucial to understand the complete picture. Solar panel production does require significant resources

Get Price

Solar Panel Manufacturing''s Environmental Impact:

Water conservation in solar panel manufacturing has become increasingly sophisticated through innovative production techniques and

Get Price

Research finds that returning solar panel production to U.S. can

Manufacturing crystalline silicon photovoltaic panels in the U.S. solves logistical challenges and eases greenhouse gas problems, according to the researchers. By 2050, the

Get Price

Life Cycle Greenhouse Gas Emissions from Solar Photovoltaics

Analysts developed and applied a systematic approach to review LCA literature, identify primary sources of variability and, where possible, reduce variability in life cycle GHG emissions

Get Price

How do the greenhouse gas emissions from solar panel

Comparing the greenhouse gas emissions from solar panel manufacturing to those from fossil fuel extraction and processing reveals a significantly lower environmental impact for

Get Price

Carbon Footprint of Solar Panel Manufacturing

PV panels have a nearly non-existent carbon footprint, around 40 grams per kWh of electrical energy produced. This only comes from the

Get Price

Solar Photovoltaic Manufacturing Basics

Solar Photovoltaic Manufacturing Basics Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal

Get Price

Greenhouse gas emissions embodied in the U.S. solar

Eighty-five percent of the embodied GHG emissions are from PV panel production processes in China and other Asia–Pacific countries.

Get Price

Understanding the Carbon Footprint of Solar Panel

Learn the carbon footprint of solar panel manufacturing, its lifecycle emissions, and strategies for better sustainability for a greener future.

Get Price

The Environmental Impact of Solar Panel Production

Solar panel manufacturing involves multiple steps, including wafer production, cell fabrication, and module assembly. Each step requires energy

Get Price

Life cycle greenhouse gas emissions and energy footprints of

The life cycle energy profile for a utility-scale solar power plant shows that most of the energy is consumed during raw material extraction, production, and assembly of solar

Get Price

Does making solar panels cause pollution

This blog post will explore the materials used in solar panels, the energy consumption and pollution associated with their production, and how their environmental

Get Price

Analogical environmental cost assessment of silicon flows used in solar

This study provides valuable insights into the environmental impacts of these two major solar panel manufacturing countries by examining the silicon life cycle, from production

Get Price

Research finds that returning solar panel production to

Manufacturing crystalline silicon photovoltaic panels in the U.S. solves logistical challenges and eases greenhouse gas problems, according

Get Price

Solar energy and the environment

Solar energy technologies and power plants do not produce air pollution or greenhouse gases when operating. Using solar energy can have a positive, indirect effect on the environment

Get Price

PVI17_Publishers_Foreword dd

A cheaper, faster and greener solar panel manufacturing process George-Felix Leu, Chris Egli & Edgar Hepp, Oerlikon Solar, Trübbach, Switzerland, &

Get Price

6 FAQs about [Gas consumption in solar panel production]

How much energy does a solar panel use?

The energy consumed during the life cycle is estimated to be 3.1 × 10 7 kWh e. Upstream processes related to raw material extraction and production of solar PV panel assembly are the largest contributor, 53% of the total consumption. Upgrading silicon ore into a usable form for solar cells alone consumes 37% of this energy.

How do solar PV panels affect energy consumption?

From an input materials and energy point of view, 45% of the embodied emissions of solar PV panels are associated with the electricity consumed during silicon and PV manufacturing, while 25% and 12% of the emissions are from emissions of aluminum and glass production, respectively.

How does solar panel manufacturing affect the environment?

The mining and processing of these materials pose significant environmental consequences, including habitat destruction, soil erosion, water pollution, and greenhouse gas emissions. Solar panel manufacturing involves multiple steps, including wafer production, cell fabrication, and module assembly.

What is solar panel manufacturing?

Solar panel manufacturing involves multiple steps, including wafer production, cell fabrication, and module assembly. Each step requires energy and emits greenhouse gases. Energy-intensive processes like wafer production contribute to the overall carbon footprint of solar panel production.

How much energy does a solar PV module consume?

The module assembly also has a significant contribution to the energy consumption of the solar PV production stage. Upstream energy consumed in aluminum production is responsible for a large share. According to the life cycle inventory analysis, each panel requires around 67.4 kWhe to produce the aluminum frames needed.

How much CO2 does a solar panel emit?

It prompts emissions from 37.3 to 72.2 g CO2e/kWh when installed in regions with high solar irradiance, depending on the energy mix of manufacturing location and the efficiency of production processes. Additionally, transportation, installation, and maintenance add to the carbon footprint of solar panels.

More related information

-

Oman Solar Panel Production Project

Oman Solar Panel Production Project

-

Solar panel production market share

Solar panel production market share

-

Communication base station solar panel production company

Communication base station solar panel production company

-

Photovoltaic solar panel production in Zambia

Photovoltaic solar panel production in Zambia

-

Estonian solar panel production companies

Estonian solar panel production companies

-

Latest expansion of solar panel production

Latest expansion of solar panel production

-

Selling solar photovoltaic panel production equipment standards

Selling solar photovoltaic panel production equipment standards

-

Angola solar panel production company

Angola solar panel production company

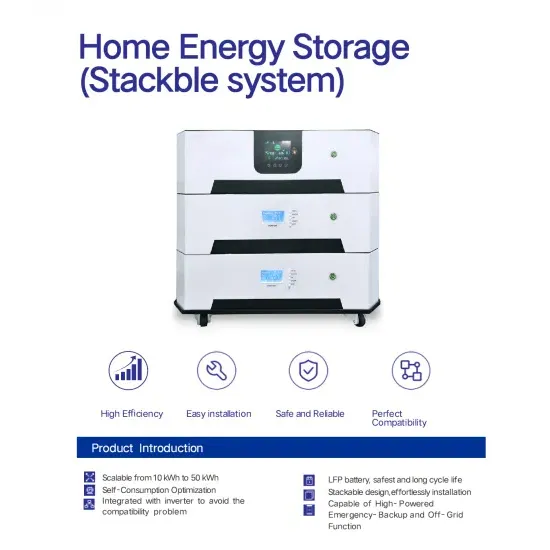

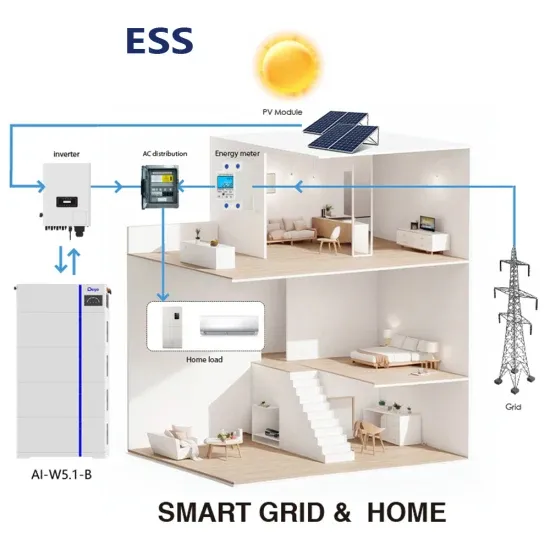

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.