How to Calculate How Long an Inverter Will Last

Most inverters are 24V, so make sure your batteries have matching voltage. If you want to run a solar panel system, use either 24V panels or connect 12V panels in a series to increase the

Get Price

Inverter Size Calculator – self2solar

However, many systems use a DC-to-AC ratio greater than 1 (often 1.1 to 1.2) to maximize energy harvest despite inverter clipping losses.

Get Price

Inverter Current Calculator

Enter the input voltage of the inverter system (typically 12V, 24V, or 48V DC). Click "Calculate" to find out the current the inverter will draw from the battery or DC power source.

Get Price

Sizing Your Charge Controller & Inverter

For a grid tie inverter, you''ll need to know the total peak input voltage from your PV array or wind turbine +25% to compensate for surges, as well as the AC

Get Price

Understanding inverter voltage

The cut-off inverter voltage is a crucial parameter that determines when the inverter should cease operating to prevent damage to the connected

Get Price

Inverter Specifications and Data Sheet

The article provides an overview of inverter functions, key specifications, and common features found in inverter systems, along with an example of power calculations and inverter

Get Price

Inverter Specifications and Data Sheet

Finding the proper inverter size for your needs is as simple as adding together the necessary wattages of the items that you''re looking to power.

Get Price

What Is an Inverter: Inverter Ratings, Efficiency & More

To obtain 230 volts from a 115 volt inverter, either use two inverters "stacked" (if they are designed for that) or use a transformer to step up the voltage.

Get Price

Inverter Calculator

Change values in the boxes with arrows and the calculator will adjust to show you other system specifications: Inverter Input Inverter Power Rating Inverter Output 12VDC 24VDC 48VDC

Get Price

How many volts does the energy storage inverter have?

Most residential energy storage inverters function within a common voltage range of 12V to 60V. This voltage range is ideal for smaller setups, such as home battery systems

Get Price

How to calculate solar panel amps

For example, if the solar panel is rated at 175 watts and the maximum power voltage, Vmp, is given as 23.6 volts, then calculate the current as 175 watts divided by 23.6

Get Price

Inverter Power Calculator & Formula Online Calculator Ultra

High-efficiency inverters waste less power as heat and are more economical to use. How does rated power affect inverter selection? The rated power determines the maximum

Get Price

How Many Solar Panels Can I Connect to an Inverter?

When deciding how many solar panels can be connected to an inverter, there are several important specifications to consider: Maximum Input Voltage: This is

Get Price

How many amps does a 3000 watt inverter draw

In this article, we are going to learn about how many amps does a 3000 watt inverter draw, formula to calculate the maximum amp draw of the

Get Price

What Will An Inverter Run & For How Long? (With Calculator)

Our batteries come in different voltages (12,24, & 48v) But AC appliances required 120 volts (because our grid power comes in 120 volts). So an inverter will convert the lower

Get Price

What Will An Inverter Run & For How Long? (With

Our batteries come in different voltages (12,24, & 48v) But AC appliances required 120 volts (because our grid power comes in 120 volts). So

Get Price

How Many Amps Does a 1000 Watt Inverter Draw?

Is your 1000 watt inverter enough? Use these simple calculations to find out how many amps a 1000 watt inverter can draw.

Get Price

How many volts does solar photovoltaic power generation have?

The voltage output of solar panels generally ranges from 12 to 48 volts, but this can vary significantly based on the panel size, efficiency, and other factors. Choosing the right

Get Price

Inverter Calculator

In order to ensure that the capacity of your power inverter is sufficient to meet the required start up load, you must first determine the power consumption of the equipment or appliance you plan

Get Price

Understanding inverter voltage

The cut-off inverter voltage is a crucial parameter that determines when the inverter should cease operating to prevent damage to the connected battery. For a 12V inverter, the

Get Price

Solar Power Basics for Beginners: Volts, Amps,

To calculate the current a charge controller has to be able to manage, use the total power output (watts) from the solar panels and the

Get Price

How many volts does a solar generator produce?

1. SOLAR GENERATOR VOLTAGE OVERVIEW, 2. COMMON OUTPUT RANGE, 3. INVERTER FUNCTIONALITY, 4. APPLICATIONS AND

Get Price

How Many Watts Does Your Refrigerator Need: Choosing the Right Inverter

As mentioned earlier, the inverter should have sufficient surge capacity to handle the starting surge of the refrigerator. Make sure to choose an inverter that can handle the

Get Price

Inverter Amp Draw Calculator

To calculate the amp draw for inverters at different voltages, you can use this formula. Maximum Amp Draw (in Amps) = ( Watts ÷ Inverter''s

Get Price

Inverter Calculator

In order to ensure that the capacity of your power inverter is sufficient to meet the required start up load, you must first determine the power consumption of the

Get Price

Inverter Amp Draw Calculator

To calculate the amp draw for inverters at different voltages, you can use this formula. Maximum Amp Draw (in Amps) = ( Watts ÷ Inverter''s Efficiency (%)) ÷ Lowest Battery

Get Price

Inverter Battery Voltage: How Many Volts Are Needed For

An inverter battery typically operates at 12V, 24V, or 48V. These voltages represent the nominal direct current (DC) needed for the inverter''s function.

Get Price

What Size Inverter Do I Need?

Finding the proper inverter size for your needs is as simple as adding together the necessary wattages of the items that you''re looking to power.

Get Price

All You Need to Know about Amps, Watts, and Volts in Solar

Understand Amps, Watts, and Volts in Solar energy systems with our comprehensive guide. Learn how these key electrical units impact solar power efficiency and performance. Perfect

Get Price

How many volts does the energy storage inverter have?

Most residential energy storage inverters function within a common voltage range of 12V to 60V. This voltage range is ideal for smaller setups,

Get Price

6 FAQs about [How many volts does the inverter have in total ]

What voltage does an inverter use?

In different countries, the applicable AC voltage is different, and most countries use 110v, 120v output inverter voltage. You can confirm on the search engine or see how much AC voltage the home appliance label uses. How can the quality of inverter output voltage be measured?

Does an inverter convert a battery into a 120 volt battery?

Our batteries come in different voltages (12,24, & 48v) But AC appliances required 120 volts (because our grid power comes in 120 volts). So an inverter will convert the lower voltage of the battery into 120 volts in order to run AC appliances If playback doesn't begin shortly, try restarting your device.

What voltage is a 12V inverter?

Inverters come in various configurations, each designed for specific power systems. Common rated input voltages include 12V, 24V, and 48V. The choice depends on the application, the size of the power system, and the available power source. A 12V inverter is commonly used for smaller applications, such as in vehicles or small off-grid setups.

Why is inverter voltage important?

In the realm of power electronics, the inverter voltage is a critical parameter that dictates its performance, compatibility, and safety. Understanding the intricacies of inverter voltage is essential for anyone seeking a reliable and efficient power supply.

What is a start inverter voltage?

The start inverter voltage is the minimum input voltage required for the inverter to initiate the conversion process. In the case of a 12V inverter, the start inverter voltage is typically around 9.5VDC. This threshold ensures that the inverter can begin its operation reliably without placing undue stress on the connected battery.

What is an example of a power inverter?

Common examples are refrigerators, air-conditioning units, and pumps. AC output voltage This value indicates to which utility voltages the inverter can connect. For inverters designed for residential use, the output voltage is 120 V or 240 V at 60 Hz for North America. It is 230 V at 50 Hz for many other countries.

More related information

-

How many volts can a 12v inverter handle

How many volts can a 12v inverter handle

-

How many volts can the inverter withstand

How many volts can the inverter withstand

-

How many volts does the inverter use

How many volts does the inverter use

-

220v 370w water pump inverter total inverter size

220v 370w water pump inverter total inverter size

-

How many watts does a 24V to 220V inverter have

How many watts does a 24V to 220V inverter have

-

How much power does a home inverter have

How much power does a home inverter have

-

Total effective value of inverter voltage

Total effective value of inverter voltage

-

How to bid for a communication base station inverter grid-connected project

How to bid for a communication base station inverter grid-connected project

Commercial & Industrial Solar Storage Market Growth

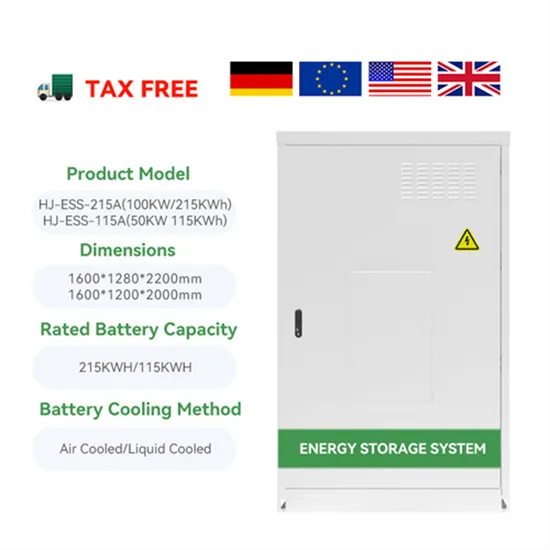

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.