12 Volt Power Consumption Calculator – Calculator

Calculating 12 Volt Power Consumption It''s crucial to know how much power your 12 volt system uses. This helps you make the best choices for your power use and battery life.

Get Price

12V, 24V, or 48V Solar Power System: Which Voltage Is Best for

Simply put, if you have a 12V system, you need a 12V inverter; a 48V system requires a 48V inverter. Standard Pure Sine Wave inverters simply change DC power to AC power. Inverter

Get Price

Inverters 101: Understanding amps and volts

Note that on the 12-volt side of the inverter you need 1,200 watts going in, which works out to 100 amps x 12 volts = 1,200 watts. But on the 120-volt side of the inverter you get

Get Price

Tips to Choose the Right Inverter for Homes: 12V or 24V

Inverter size is another key consideration when choosing between a 12 volt and a 24 volt inverter. The size of the inverter determines its capacity

Get Price

Understanding inverter voltage

For a 12V inverter, the maximum input inverter voltage is typically around 16VDC. This safety margin provides a buffer to accommodate

Get Price

Calculate Battery Size For Any Size Inverter (Using

The input voltage of the inverter should match the battery voltage. (For example 12v battery for 12v inverter, 24v battery for 24v inverter and 48v

Get Price

How Big of an Inverter Can My Car Battery Handle?

To determine the maximum inverter power that your vehicle''s battery can support, you need to know the battery''s rated voltage (12V for

Get Price

How Many 12V Batteries for a 2000 Watt Inverter?

Understanding Power Requirements When determining how many 12V batteries are necessary for a 2000 watt inverter, it is crucial to understand the power and energy

Get Price

How Many Amps Does a 2000 Watt Inverter Draw

Here, the lowest battery voltage (before cut off) is 10 volts for 12V, 20 volts for 24V, and 40 volts for 48V battery bank. You can use the following

Get Price

Calculate Battery Size For Any Size Inverter (Using Our Calculator)

The input voltage of the inverter should match the battery voltage. (For example 12v battery for 12v inverter, 24v battery for 24v inverter and 48v battery for 48v inverter

Get Price

What size power inverter can my truck run?

I bought a 2000 watt (4000 watt peak) inverter. I want to install it into my truck with a 4.3 vortec. Does any one know if my alternator and battery

Get Price

How much power can I safely pull from a 12v cigarette lighter

One of my Christmas presents was an inverter to convert the 12v cig lighter power to 120v AC power. It says it has a max power output of 150 watts and a max surge power output of 175

Get Price

Watts, Volts, Amps Calculator – self2solar

Inverter Size: 500 watts (W) Battery Voltage: 12 volts (V) Battery Capacity: 500 Watt-Hours (Equal to 42 Amps-Hours at 12V; 500 / 12 = 42 Ah)

Get Price

4000 watt Inverter on 12 V?

Hey everyone, I know it''s preferred to have anything over 2000 watts on a 24 v or 48 v system. I plan on building a 200 Ah battery pack using Fortune cells and was going to use

Get Price

How Many Batteries can Be Connected To An Inverter?

The number of batteries you can connect to an inverter cannot be more than 12 times the inverter charging current. A 20A charger can handle 240ah battery maximum.

Get Price

What Size Inverter Do I Need?

This can be useful to find the right battery size for your inverter (which you can calculate using our handy guide) or for measuring the necessary volts. You can use the following formula to

Get Price

How Big of an Inverter Can My Car Battery Handle?

To determine the maximum inverter power that your vehicle''s battery can support, you need to know the battery''s rated voltage (12V for most automotive batteries) and the

Get Price

Inverters 101: Understanding amps and volts

Note that on the 12-volt side of the inverter you need 1,200 watts going in, which works out to 100 amps x 12 volts = 1,200 watts. But on the 120

Get Price

Inverter Battery Voltage: How Many Volts Are Needed For

A common choice for residential use is the 12-volt system, which can power small devices and appliances easily. However, larger systems and those designed for higher power

Get Price

Inverter Calculator

In order to ensure that the capacity of your power inverter is sufficient to meet the required start up load, you must first determine the power consumption of the

Get Price

12 Volt Battery Run Time Calculator

BatteryStuff Tech 17 watts / 12.5 volts = 1.36 amps. 9 of these lights will pull 12.24 amps per hour. running 8 hours is a total of 97.92 amps. The calculator recommend a battery

Get Price

Tips to Choose the Right Inverter for Homes: 12V or 24V

Inverter size is another key consideration when choosing between a 12 volt and a 24 volt inverter. The size of the inverter determines its capacity to handle power loads. 12V

Get Price

The Only Inverter Size Chart You''ll Ever Need

Inverter Size Chart We have summarized the appliances that inverters from 300W to 3000W can run depending on their rated maximum power. Note to our readers: Use the

Get Price

How many amps will an inverter draw?

This can be used to power an inverter capable of producing about 1,200 watts at 120 VAC. With your vehicle''s existing DC charging system, a 3000 watt inverter can only provide 1,200 Watts

Get Price

How Many Batteries For a 3000 Watt Inverter?

The same inverter will run at full power for an hour so on a 125ah 24V battery. Many inverters support 24V batteries, and while these batteries cost more you can get by with a smaller

Get Price

Calculating Pure Sine Wave Inverter power draw

For a more accurate calculation of battery current: Divide load watts by actual battery voltage, this will be in the range 12-14V (24-28V). Then to allow for inverter efficiency, typically 85%, divide

Get Price

What Size Inverter Do I Need?

This can be useful to find the right battery size for your inverter (which you can calculate using our handy guide) or for measuring the necessary volts. You

Get Price

Inverter Calculator

In order to ensure that the capacity of your power inverter is sufficient to meet the required start up load, you must first determine the power consumption of the equipment or appliance you plan

Get Price

Understanding inverter voltage

For a 12V inverter, the maximum input inverter voltage is typically around 16VDC. This safety margin provides a buffer to accommodate fluctuations in the power source and

Get Price

How Much Power Can a 12V Battery Give? Full

A 12V battery can give a lot of power. It all depends on how it is used. If you are using it to run a small appliance, then it will not give as much

Get Price

6 FAQs about [How many volts can a 12v inverter handle ]

What voltage should a 12V inverter run on?

The input voltage of the inverter should match the battery voltage. (For example 12v battery for 12v inverter, 24v battery for 24v inverter and 48v battery for 48v inverter Summary What Will An Inverter Run & For How Long?

How many Watts Does a 12 volt inverter use?

Here’s a diagram with a 12-volt battery, an inverter and a 1,200-watt microwave oven. Note that on the 12-volt side of the inverter you need 1,200 watts going in, which works out to 100 amps x 12 volts = 1,200 watts. But on the 120-volt side of the inverter you get 1,200 watts coming out, which works out to 10 amps x 120 volts = 1,200 watts.

How do I choose a 12 volt or 24 volt inverter?

Inverter size is another key consideration when choosing between a 12 volt and a 24 volt inverter. The size of the inverter determines its capacity to handle power loads. 12V Inverter Size: 12V inverters are typically available in smaller sizes and may have limitations in terms of the maximum power they can supply.

How many watts is a 120 volt inverter?

But on the 120-volt side of the inverter you get 1,200 watts coming out, which works out to 10 amps x 120 volts = 1,200 watts. It works out to an approximate 10:1 or 1:10 conversion factor depending if you’re converting from 12 volts to 120 volts, or 120 volts to 12 volts.

What is a 12V to 240V inverter?

A 12V to 240V inverter is a pivotal device designed to convert direct current (DC) power from a 12-volt battery into alternating current (AC) power with a nominal output of 240 volts. This conversion is vital for running household appliances, electronic devices, and other equipment that require standard AC power.

What voltage does an inverter use?

In different countries, the applicable AC voltage is different, and most countries use 110v, 120v output inverter voltage. You can confirm on the search engine or see how much AC voltage the home appliance label uses. How can the quality of inverter output voltage be measured?

More related information

-

How much does a 12v 3kw inverter cost

How much does a 12v 3kw inverter cost

-

How to choose a 12v inverter

How to choose a 12v inverter

-

Can a 12v inverter handle 265w

Can a 12v inverter handle 265w

-

How many volts does a 48v inverter usually have

How many volts does a 48v inverter usually have

-

How big an inverter is needed to convert 12V to 72V

How big an inverter is needed to convert 12V to 72V

-

12v inverter turns into 220 volts AC

12v inverter turns into 220 volts AC

-

How many volts does the inverter have in total

How many volts does the inverter have in total

-

How many volts does a 60v inverter output

How many volts does a 60v inverter output

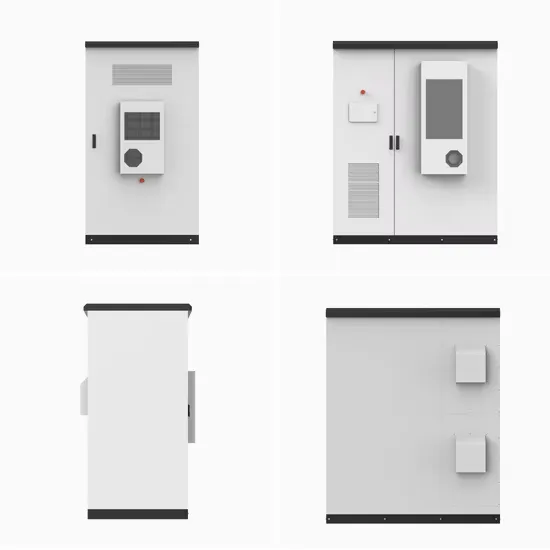

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.