Mastering the Art of Lithium Battery Pack Assembly: A

Mastering the Art of Lithium Battery Pack Assembly. Join me on an adventure into the fascinating world of lithium battery pack assembly. As we explore the intricate craft of

Get Price

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

Assembling your own custom battery pack allows you to tailor a power solution to your specific needs, whether for an electric vehicle, solar storage system, robotics project or

Get Price

Lithium Titanate Battery LTO | EVlithium

LTO battery(Li4Ti5O12) is a lithium ion battery with lithium titanate as the anode. It has been widely used because of its high safety, high stability, excellent

Get Price

How Are Lithium Battery Packs Assembled?

The assembly process of lithium battery packs is crucial for ensuring their optimal performance, safety, and longevity. This article explores the key steps involved in lithium battery pack

Get Price

How to Build a Lithium Ion Battery Pack? A Step by

Proper assembly will not only produce a battery that can function properly, but also help keep us safe while using the lithium-ion battery pack.

Get Price

Mastering the Art of Lithium Battery Pack Assembly: A

Mastering the Art of Lithium Battery Pack Assembly. Join me on an adventure into the fascinating world of lithium battery pack assembly. As we

Get Price

How to Build a Lithium Ion Battery Pack? A Step by Step Guide

Proper assembly will not only produce a battery that can function properly, but also help keep us safe while using the lithium-ion battery pack. Below is a list of materials and tools

Get Price

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

In this step-by-step guide, as a professional lithium battery pack manufacturer, I''ll walk you through the entire DIY battery pack assembly process to help you build a safe, high

Get Price

How to charge lithium titanate battery pack

1. Charging new battery packs . When you get a new lithium-ion battery pack, you don''''t need to discharge and charge its first cycle fully. These cells have a maximum capacity that is

Get Price

48V 20Ah Lithium titanate Oxide (LTO) Battery Pack

Description Features Lithium Titanate (LTO):the Safest Lithium Technology Integrated Battery Management System (BMS) Performance Long Cycle Life > 10000cycles@ 80%DOD. High

Get Price

Lithium-ion Battery Pack Manufacturing Process

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get Price

Lithium-Ion Battery Assembly Process & Key Stages Explained

Discover the key stages in the lithium-ion battery assembly process, from raw materials to pack assembly. Learn how battery-making machines ensure precision, safety, and

Get Price

Lithium Battery Pack Assembly: A Comprehensive Guide

Join us as we delve into the intricate art of lithium battery pack assembly, unveiling the expertise and precision engineering required to bring these cutting-edge technologies to life.

Get Price

Lithium Titanate Battery Buildlog #5

Started preparing for mounting the battery pack itself inside the box.more. Some more progress on the battery pack in this build log - made the 4AWG battery cables, connected up the

Get Price

Custom Lithium-ion Battery Pack Manufacturer & Assembly

Lithium-ion battery pack manufacturing process includes separate cell sorting, assembly, and insulation stages to ensure high performance, safety, and longevity for all of our custom

Get Price

Yinlong LTO 66160 12V 45ah 40ah Lithium Titanate Battery Pack

Buy Yinlong LTO 66160 12V 45ah 40ah Lithium Titanate Battery Pack High-power Bulid in 5A Balancer for Car Audio Outdoor Engineering at Aliexpress for . Find more 44, 52801 and 629

Get Price

Can I Assemble My Own Lithium Battery at Home?

Yes, you can assemble a lithium battery at home—but it''s far more complex and hazardous than most DIYers realize. With the rise of solar power and electric vehicles, lithium

Get Price

Battery Module: Manufacturing, Assembly and Test

In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Get Price

Beginner-Friendly Tips for Assembling Lithium Battery Packs

Learn how to assemble a lithium battery pack with beginner-friendly tips on design, safety, and tools for optimal performance and reliability.

Get Price

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this step-by-step

Get Price

Beginner-Friendly Tips for Assembling Lithium Battery

Learn how to assemble a lithium battery pack with beginner-friendly tips on design, safety, and tools for optimal performance and reliability.

Get Price

Capital Costs Involved in Setting Up a Lithium-Titanate Battery

As the world pivots towards sustainable energy and advanced mobility solutions, setting up a lithium-titanate battery plant has emerged as a lucrative opportunity for

Get Price

Lithium Battery Assembly: How to Build Battery Pack

How to build a lithium battery? Our simple, step-by-step guide walks you through the process. Dive into this beginner project today!

Get Price

ASSEMBLE LITHIUM BATTERY STEP BY STEP GUIDE TOOLS

FAQs about Cycle life of lithium titanate battery pack How long does a lithium titanate battery last? The self-discharge rate of an LTO (Lithium Titanate) battery stored at 20°C for 90 days can

Get Price

Lithium Battery Pack Assembly: A Comprehensive Guide

Join us as we delve into the intricate art of lithium battery pack assembly, unveiling the expertise and precision engineering required to bring

Get Price

How to build car audio Yinlong LTO lithium battery bank

In depth step by step building of a XS power Yinlong LTO Lithium car audio bank. Heltec balancer soldering and connections and assembly of the LAF audio LTO case. Be sure to follow manufacturer''s

Get Price

What Is a Lithium Battery Component?

6. Lithium Titanate Lithium titanate or LTO battery replaces the anode''s graphite material with titanate, and the cathode can be made of

Get Price

6 FAQs about [Assembling lithium titanate battery packs]

What is a lithium battery management system (BMS)?

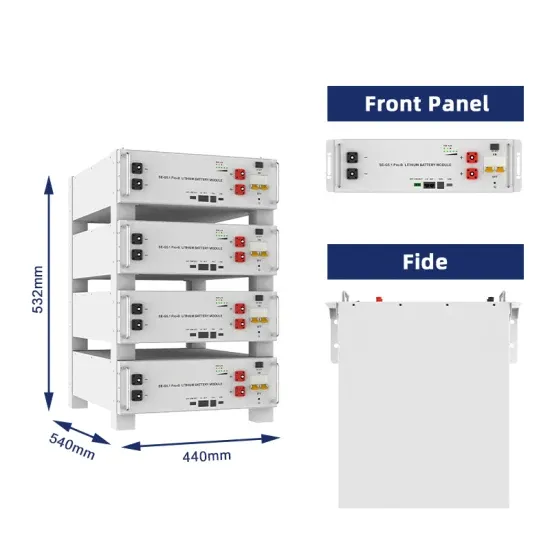

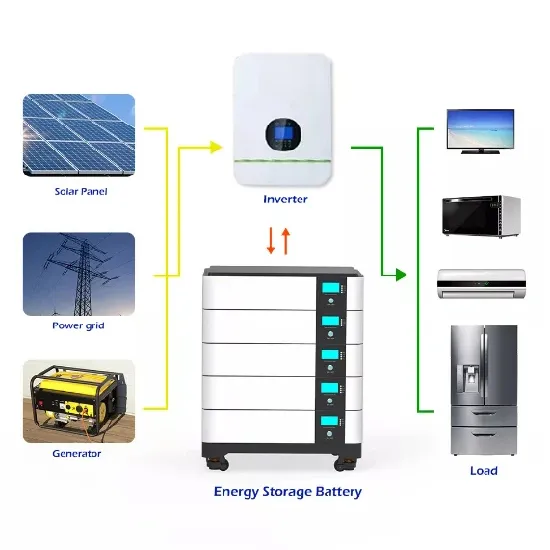

The cells within a lithium battery pack are typically arranged in series or parallel configurations to achieve the desired voltage and capacity. Additionally, a Battery Management System (BMS) is often integrated to monitor and ensure the safe operation of the battery pack.

Why is quality control important in a lithium battery pack assembly?

Consequently, this intricate step paves the way for efficient power transfer and optimal pack performance. Quality control is a cornerstone of the lithium battery pack assembly process.

How should lithium batteries be protected?

Lithium batteries should be protected from severe vibration and external impact during assembly and use to avoid damaging the battery structure and performance. In applications such as mobile equipment and electric vehicles, suitable securing and cushioning measures should be taken. 5. Pay attention to storage conditions

What is a high-performance lithium battery pack?

As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the heart of this burgeoning industry lies a meticulously orchestrated assembly process, where individual lithium-ion cells are transformed into powerful energy storage systems.

How do you test a lithium battery pack?

Voltage and Current Testing: Use a multimeter to ensure the pack operates within safe parameters. Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations.

How to build a lithium battery?

Part 4. Conclusion Building a lithium battery involves several key steps. First, gather the necessary materials, including lithium cells, a battery management system, connectors, and protective casing. Begin by designing the battery layout, ensuring proper spacing and alignment of cells.

More related information

-

How many strings of 48v lithium battery packs

How many strings of 48v lithium battery packs

-

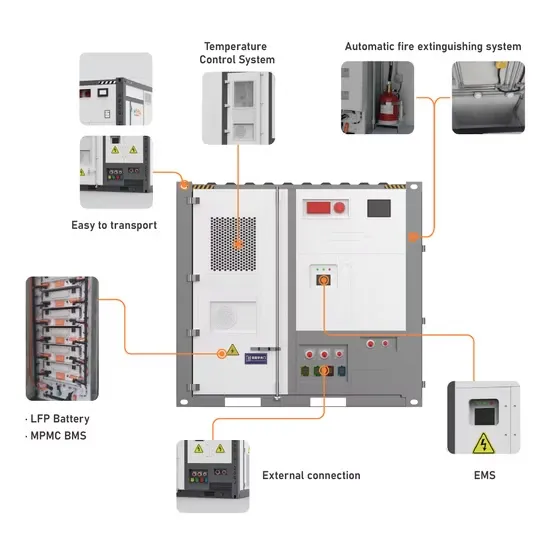

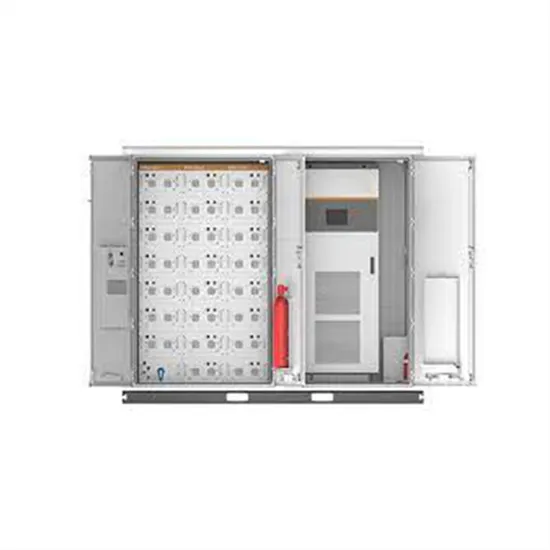

Angola Lithium Titanate Battery Energy Storage Container Quote

Angola Lithium Titanate Battery Energy Storage Container Quote

-

How many strings of 24V lithium battery packs are needed

How many strings of 24V lithium battery packs are needed

-

Can lithium battery packs be used with inverters

Can lithium battery packs be used with inverters

-

Lithium battery packs used in series and parallel

Lithium battery packs used in series and parallel

-

Lithium titanate battery pack customization

Lithium titanate battery pack customization

-

Production of dual lithium battery packs

Production of dual lithium battery packs

-

Polish wide temperature lithium titanate battery pack

Polish wide temperature lithium titanate battery pack

Commercial & Industrial Solar Storage Market Growth

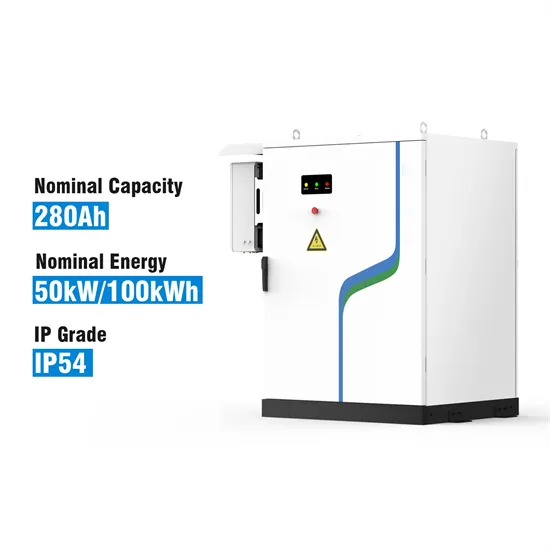

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.