Electromagnetic and Rotational Characteristics of a

A 2 kW/28.5 kJ superconducting flywheel energy storage system (SFESS) with a radial-type high-temperature superconducting (HTS) bearing

Get Price

Thermal Packaging of High Temperature Superconductor Bulk for

A micro flywheel energy storage system has been developed using a high temperature superconductor bearing. In the previous paper, the micro flywheel was fabricated and

Get Price

$200 Million For Renewables-Friendly Flywheel Energy Storage

1 day ago· $200 Million For Advanced Energy Storage Torus Energy is among the flywheel innovators ready to push their technology into the market here and now.

Get Price

A micro high-temperature superconductor-magnet flywheels with

This paper proposes an energy storage and attitude control system for micro-electromechanical systems (MEMS) in spacecraft using a high-temperature superconductor (HTS) magnet

Get Price

FLYWHEEL ENERGY STORAGE SYSTEMS WITH

This project''s mission was to achieve significant advances in the practical application of bulk high-temperature superconductor (HTS) materials to energy-storage

Get Price

Superconducting Bearing Design for Outer Rotor Flywheel

Abstract— This paper describes the application of lumped parameter modeling techniques to designing high temperature superconducting bearings for outer-rotor flywheel energy storage

Get Price

Energy Storage with Superconducting Magnets: Low

The global development of both Low-Temperature Superconductor (LTS) and High-Temperature Superconductor (HTS) SMES systems highlights

Get Price

Study of Magnetic Coupler With Clutch for Superconducting Flywheel

High-temperature superconducting flywheel energy storage system has many advantages, including high specific power, low maintenance, and high cycle life. However, its self

Get Price

Optimizing superconducting magnetic bearings of HTS flywheel

The superconducting flywheel system exploiting the magnetic coupling between the bulk high temperature superconductors (HTSs) and permanent magnets (PMs) exhibits

Get Price

Study of a High-temperature Superconducting Magnetic

The RTRI conducted a development of a superconducting magnetic bearing applicable to the flywheel energy storage system for railways. In this study, a high-temperature bulk

Get Price

Design and Research of a High-Temperature Superconducting Flywheel

A novel energy storage flywheel system is proposed, which utilizes high-temperature superconducting (HTS) electromagnets and zero-flux coils. The electrodynamic suspension

Get Price

Development of 1kWh Flywheel Energy Storage System with

Abstract – Development of flywheel energy storage system using high temperature superconducting magnetic bearing is actively attempted. 1kWh flywheel was developed and

Get Price

Superconducting Bearings for Flywheel Energy Storage

While past applications of the flywheel have used conventional mechanical bearings that had relatively high losses due to friction, the development of magnetic bearings constructed using

Get Price

Static properties of high temperature superconductor bearings for

Many aspects of the dynamic behavior of flywheel rotors still need to be examined closely, and the rotors require a high capacity supporting system such as high temperature

Get Price

Flywheel Energy Storage System with Superconducting

During the five-year period, we carried out two major studies - one on the operation of a small flywheel system (built as a small-scale model) and the other on superconducting magnetic

Get Price

Suspended Kinetic Energy Storage Based on High-Temperature Superconductors

Abstract The paper gives an overview of foreign developments of flywheel energy storage systems for hybrid power plants, describes the design of the first in Russia 5 MJ

Get Price

Theoretical calculation and analysis of electromagnetic

This article introduces a high-temperature superconducting flywheel energy storage system that utilizes high-temperature superconducting magnets and zero flux coils as

Get Price

Bearingless high temperature superconducting flywheel energy storage

In order to solve the problems such as mechanical friction in the flywheel energy storage system, a shaftless flywheel energy storage system based on high temperature superconducting (HTS)

Get Price

Superconducting Bearings for Flywheel Energy Storage

While past applications of the flywheel have used conventional mechanical bearings that had relatively high losses due to friction, the development of

Get Price

Superconducting Energy Storage Flywheel —An Attractive

The superconducting energy storage flywheel comprising of mag-netic and superconducting bearings is fit for energy storage on account of its high efficiency, long cycle life, wide

Get Price

Bearingless high temperature superconducting flywheel energy

In order to solve the problems such as mechanical friction in the flywheel energy storage system, a shaftless flywheel energy storage system based on high temperature superconducting (HTS)

Get Price

Design and Research of a High-Temperature Superconducting

A novel energy storage flywheel system is proposed, which utilizes high-temperature superconducting (HTS) electromagnets and zero-flux coils. The electrodynamic suspension

Get Price

An overview of Boeing flywheel energy storage systems with high

An overview summary of recent Boeing work on high-temperature superconducting (HTS) bearings is presented. A design is presented for a small flywheel energy storage system

Get Price

Flywheel energy storage using superconducting magnetic bearings

The abilitp of high-temperature superconducting (HTS) bearings to exhibit lop rotational loss makes possible high-efficiencp flppheel energp storage (FES). In this paper, pe

Get Price

Analysis of mechanical and quench behavior in high-temperature

Firstly, utilizing the geometric configuration of the high-temperature superconducting (HTS) energy storage coil, a finite element model of the multi-layer composite structure of the

Get Price

Static properties of high temperature superconductor bearings for

Abstract A superconductor flywheel energy storage system (SFES) is mainly used as an electro-mechanical battery which transforms electrical energy into mechanical energy and vice versa.

Get Price

A new flywheel energy storage system using hybrid

The high temperature superconductor (HTS) YBaCuO coupled with permanent magnets has been applied to construct the superconducting magnetic bearings (SMB) which can be utilized in

Get Price

More related information

-

Sudan flywheel energy storage is installed on the roof

Sudan flywheel energy storage is installed on the roof

-

How much does a flywheel energy storage rectifier module cost

How much does a flywheel energy storage rectifier module cost

-

Does flywheel energy storage increase in speed as it is stored

Does flywheel energy storage increase in speed as it is stored

-

Flywheel energy storage at Tunisia power plant

Flywheel energy storage at Tunisia power plant

-

Flywheel Energy Storage Wheel

Flywheel Energy Storage Wheel

-

Flywheel energy storage compartment

Flywheel energy storage compartment

-

Which flywheel energy storage company is the largest

Which flywheel energy storage company is the largest

-

Signal Tower Flywheel Energy Storage

Signal Tower Flywheel Energy Storage

Commercial & Industrial Solar Storage Market Growth

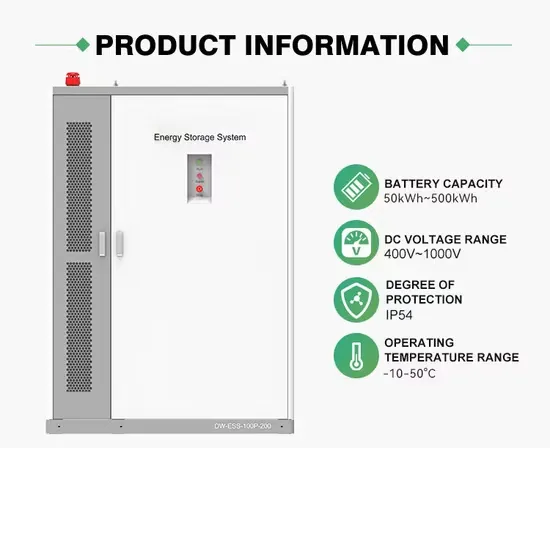

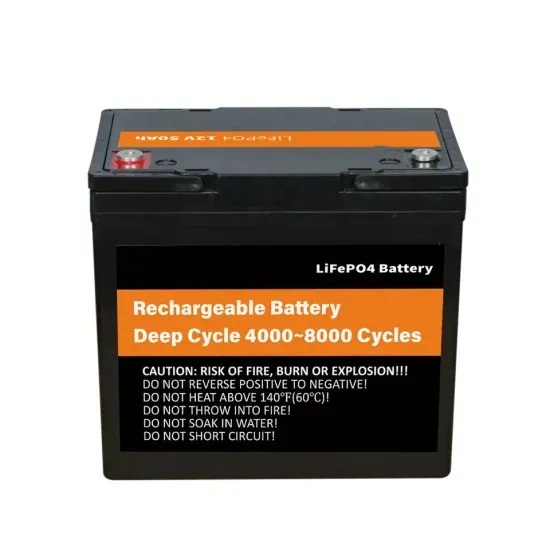

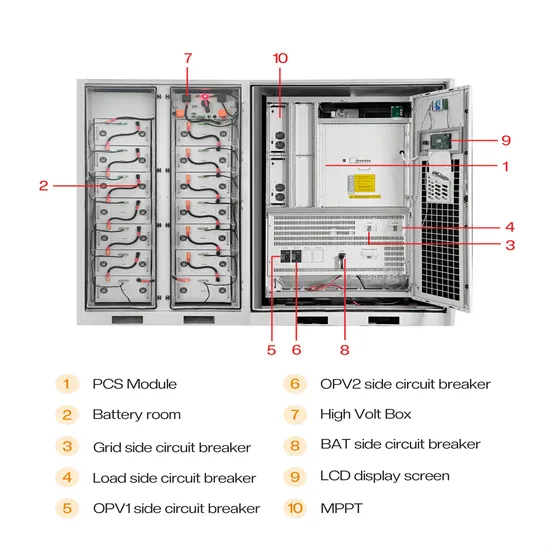

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.