Implementation of closed loop control technique for

trategy of the inverter must guarantee its output waveforms to be sinusoidal with fundamental harmonic. For this purpose, close loop current control strategies such as H∞ repetitive

Get Price

Synchronized SVPWM schemes for closed-loop current control of

The modulation index fluctuates when a closed-loop current control system is used to control the motor winding current. In addition, the angle of the voltage vector output from the

Get Price

Three-Phase Voltage Source Inverter

Configure the voltage switching function for continuous vector modulation or inverter switch input signals. You can incorporate the block into a closed-loop model to simulate a power inverter.

Get Price

Detailed analysis of closed-loop control of output-voltage

Abstract— This paper investigates the design and application of selective controllers for voltage-source-inverter output control. These controllers can be applied to minimise the effects of the

Get Price

Detailed analysis of closed-loop control of output-voltage

The design and application of selective controllers for voltage-source-inverter output control in single-phase and three-phase applications are investigated.

Get Price

Current Regulated Voltage Source Inverter | CLosed

Although Current Regulated Voltage Source Inverter operates as a CSI, it does not use large dc inductor and filter capacitors, hence it has lower weight,

Get Price

Closed loop control of boost converter with VSI

A closed-loop control of a boost converter with a Voltage Source Inverter (VSI) is a two-stage power conversion system where:

Get Price

Current-Controlled Voltage Source Inverter

A current-controlled voltage source inverter (CCVSI) is defined as a type of inverter that operates as a current source, allowing for fast response in power flow control by adjusting the switching

Get Price

Closed Loop Control of Three Phase Multilevel Inverter for

Abstract—In this paper harmonic reduction of three phase diode clamped multilevel inverter for grid connected solar system is analyzed. Solar system is controlled and maximum power is

Get Price

A Simplified Digital Closed-loop Current Control of Three-phase

An adoption of SiC device brings benefits on performances of three-phase photovoitaic (PV) inverters. As the switching loss of SiC devices is concentrated at a turn-on instant, triangular

Get Price

Three-Phase Voltage Source Inverter

Configure the voltage switching function for continuous vector modulation or inverter switch input signals. You can incorporate the block into a closed-loop

Get Price

Three-Phase Voltage Source Inverter

The Three-Phase Voltage Source Inverter block implements a three-phase voltage source inverter that generates neutral voltage commands for a balanced three-phase load. Configure the

Get Price

A Simulink-Based Closed Loop Current Control of Photovoltaic Inverter

The closed loop control of quasi-Z-source regulates the shoot through duty ratio and the modulation index to effectively control the power and maintain the strict current and

Get Price

Detailed analysis of closed-loop control of output-voltage

The paper investigates the closed-loop stability of the resulting systems thoroughly and explains the controller design process from the frequency-response viewpoint.

Get Price

Double closed-loop control strategy of LCL three-phase grid

Grid-connected inverter is an important part of the grid-connected system. Compared with the traditional L or LC filter, LCL filter has a better high-frequency harmonic attenuation

Get Price

(PDF) Close Loop V/F control of Voltage Source

In this paper, a switching frequency has been formulated for grid-connected voltage source inverter (VSI) operated using the Continuous

Get Price

Generalized Closed-Loop Control Schemes with Embedded

The proposed GCC scheme has a single-loop control of inverter output (voltage or current) and two parallel virtual impedance terms using additional measurements.

Get Price

Three-phase inverter closed-loop control based on SVPWM drive

This paper innovatively uses script module programming of plecs software to build the SVPWM modulation module which drive the three-phase inverter while realizing the closed

Get Price

Voltage Source Inverter Reference Design (Rev. E)

This reference design uses devices from the C2000 microcontroller (MCU) family to implement control of a voltage source inverter. An LC output filter is used to filter the switching component

Get Price

Dual-loop Control Strategy for Grid-connected Inverter with LCL Filter

As to the concrete topology of three-phase LCL type grid-connected inverter with damping resistance, mathematical model was deduced in detail, using method of equivalent

Get Price

Current Regulated Voltage Source Inverter | CLosed Loop Control

Although Current Regulated Voltage Source Inverter operates as a CSI, it does not use large dc inductor and filter capacitors, hence it has lower weight, volume and cost and faster dynamic

Get Price

(PDF) Close Loop V/F control of Voltage Source Inverter using

In this paper, a switching frequency has been formulated for grid-connected voltage source inverter (VSI) operated using the Continuous Control Set-Predictive Current Control

Get Price

Frequency-Domain Modeling of Harmonic Interactions

Power electronic systems, for example the voltage-source inverter (VSI) with its passive components and control (Figure 1), form closely coupled

Get Price

Modelling, control design, and analysis of the inner

This figure presents the schematic of the inner controller-based primary control for a single-phase voltage source inverters. It also highlights

Get Price

V/F Control: Open and Closed Loop V/F Control

Closed Loop V/F Control The basis of constant V/F speed control of induction motor is to apply a variable magnitude and variable frequency voltage to the

Get Price

International Journal of Soft Computing and Engineering

This paper analysis the speed control system of Induction motor fed by voltage source Inverter with implementation of Proportional Integral (PI) controller in the feedback path

Get Price

Voltage Source Inverter

The inverter is controlled with an outer voltage control loop and an inner current control loop. The DC-link voltage is measured and compared against a voltage set point.

Get Price

6 FAQs about [Voltage source inverter closed loop control]

How does a closed-loop voltage source inverter work?

This demonstration shows a closed-loop controlled 3-phase voltage source inverter operating as an active rectifier. A stiff three-phase voltage source with line inductance is connected to the AC-side of a 2-level IGBT con-verter. The DC-side of the inverter is connected to a load, modeled as an ideal current source, via a DC-link capacitor.

How do I use a closed voltage & current loop?

On the powerSUITE page, select Closed Voltage and Current Loop under Project Options. Select AC for output. Select SDFM for sensing if available on the design. Enter 60 Hz for frequency for the AC waveform. This will be the frequency of the inverter output. Under Inverter Power Stage Parameters, enter 110 VRMS for the output voltage.

How to control an inverter?

trategy of the inverter must guarantee its output waveforms to be sinusoidal with fundamental harmonic. For this purpose, close loop current control strategies such as H∞ repetitive controller, dual closed-loop feedback control, Adaptive Voltage Control, SRFPI controller, Optimal Neural Controlle

How does a DC-link inverter work?

The inverter is controlled with an outer voltage control loop and an inner current control loop. The DC-link voltage is measured and compared against a voltage set point. The error signal is converted to a d-axis current set point via a PI regulator.

What is voltage source inverter with pre-charge?

The demo model “Voltage Source Inverter with Pre-Charge” includes DC-link pre-charging resistors connected to the three-phase source to limit the inrush current at startup. The inverter is controlled with an outer voltage control loop and an inner current control loop. The DC-link voltage is measured and compared against a voltage set point.

What is a LC output filter in a high-frequency inverter?

This reference design uses devices from the C2000 microcontroller (MCU) family to implement control of a voltage source inverter. An LC output filter is used to filter the switching component in this high-frequency inverter.

More related information

Commercial & Industrial Solar Storage Market Growth

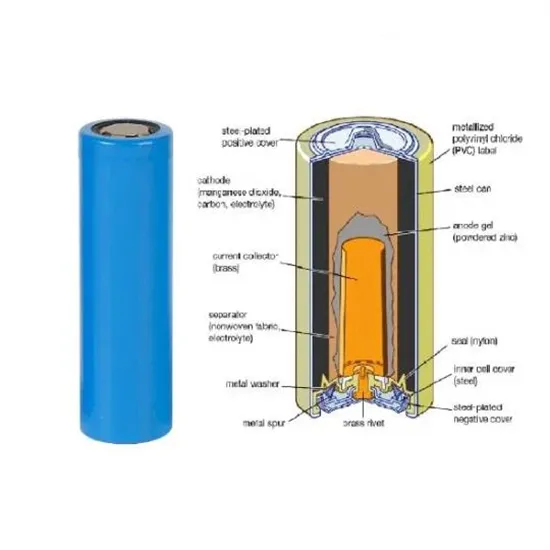

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.

Voltage Source Inverter Products

Voltage Source Inverter Products

Five-phase voltage source inverter

Five-phase voltage source inverter

Voltage source inverter with DC

Voltage source inverter with DC

Voltage Source Inverter Price

Voltage Source Inverter Price

Inverter accessible voltage range

Inverter accessible voltage range

24v inverter voltage is too high

24v inverter voltage is too high

Inverter output voltage measurement

Inverter output voltage measurement

Circulation form of voltage type inverter

Circulation form of voltage type inverter