How Is Power Output Measured In An Inverter?

Power output in inverters is measured by calculating AC voltage, current, and frequency under load. Key metrics include continuous/surge wattage (e.g., 2000W/4000W),

Get Price

Inverter Output Voltage Calculation calculation for Electrical

A higher power factor means that the load is using the power more efficiently, and this will result in a higher output voltage from the inverter. Q: How does the efficiency of the

Get Price

Inverter Motor Efficiency & Loss Evaluation | Hioki

Simultaneously measure inverter input and output power, and motor output. Evaluate inverter, motor, and overall system efficiency and loss in an accurate

Get Price

Measurement of the Conversion Efficiency of High

Three issues affecting measurement of photovoltaic systems Company A, a manufacturer of solar inverters, was dealing with a number of issues involving

Get Price

RDR-852 200W 3-Phase Inverter 4-Pole Brushless

Inverter Output Power Measurement The inverter output power (POUT) can be measured using the setup in Figure 66 due to the availability of a six-channel power analyzer (WT1806E).

Get Price

Understanding inverter voltage

The inverter output inverter voltage is a critical aspect that must align with the standard alternating current (AC) voltage required by connected

Get Price

How to measure the inverter output voltage-EEWORLD

Inverter output voltage measurement Generally speaking, for the inverter output voltage, we are concerned about the fundamental wave effective value. The 380V and 690V inverters we often

Get Price

How to Test a Pure Sine Wave Inverter? | inverter

Measure output voltage: After the inverter is powered on, use a multimeter to measure the AC output voltage. It should match the rated output of the inverter (e.g., 120V or

Get Price

Measurement of Inverter Efficiency

Achieve precise measurement of inverter efficiency by simultaneously measuring input and output power. For accurate measurements of power converters, it is necessary to measure DC power

Get Price

Inverter Voltage Measurement Methods in context of inverter voltage

This article reviews various methods for measuring inverter voltage, including direct measurement, indirect measurement, and hybrid approaches. Theoretical formulas are

Get Price

AC Power Measurement Guide

Power measurements are made by measuring the RMS current and voltage and applying the formula P = VrmsArms. Complete guide here.

Get Price

Power and Efficiency Measurement of Motors and Inverters

7 inputs, and the PX8000 Precision Power Scope, which offers both "High-precision power measurement" and "Waveform measurement with improved time resolution", providing more

Get Price

Can you Measure the Output of an Inverter?

When it comes to troubleshooting BLDC motors and inverters, there''s usually a standard strategy. You check the input to the inverter (a good 120 VAC power supply and a

Get Price

Can you Measure the Output of an Inverter?

But what about measuring the output of the inverter? This is certainly possible to do, and it can be a useful measurement, especially in hairier inverter troubleshooting scenarios.

Get Price

How to Test Inverter with Digital Multimeter

In this guide, we explain how to test an inverter with a multimeter step by step, focusing on the power input, DC bus voltage, IGBT modules, capacitors, and output terminals. With proper

Get Price

How to measure the inverter output voltage-EEWORLD

Generally speaking, for the inverter output voltage, we are concerned about the fundamental wave effective value. The 380V and 690V inverters we often talk about, as well as the voltage

Get Price

DMM for inverter output voltage measurement | FAQ | Hioki

A The output voltage of a PWM inverter contains harmonics, in addition to the fundamental wave. On the other hand, when measuring a general inverter''s output voltage, only the fundamental

Get Price

Measurement of Inverter Efficiency

Achieve precise measurement of inverter efficiency by simultaneously measuring input and output power. For accurate measurements of power converters, it is

Get Price

How to do inverter testing effectively

Voltage test: Use a multimeter to measure the input voltage and output voltage of the inverter to ensure that it is operating within the rated range. Abnormal inverter voltage may

Get Price

How to Test an Inverter

When measuring the voltage and current on the primary side of an inverter, distortions in waveforms can cause differences in measured values. Consequently, it''s necessary to use a

Get Price

How To Read And Interpret An Inverter Specification

Output Voltage Output Voltage states the AC voltage produced by the inverter, usually 120V or 230V, depending on the applicable regional standards. It is important to match it with the

Get Price

CSM_Inverter_TG_E_1_1

Power supply Rectifier (converter) PWM control Inverter The voltage output from the inverter is in pulse form. The pulses are smoothed by the motor coil, and a sine wave current flows. As a

Get Price

How to Test a Pure Sine Wave Inverter? | inverter

Measure output voltage: After the inverter is powered on, use a multimeter to measure the AC output voltage. It should match the rated output

Get Price

How to do inverter testing effectively

Voltage test: Use a multimeter to measure the input voltage and output voltage of the inverter to ensure that it is operating within the rated

Get Price

MEASURING AN INVERTER''S OUTPUT

While inverters are good tools for drivers, they do have limitations so it is important to understand how much of a load an inverter can handle. Purkeys'' Sales and Service Engineer Larry

Get Price

Measurement Device for Inverter Output Impedance Considering

Inverter output impedance is an important parameter for assessing the stability of a grid-connected system. However, measuring the inverter output impedance is not

Get Price

Measurement of Inverter Efficiency

The WT3000 offers up to our input elements capable of simultaneous measurement of single-phase input/three-phase output, or three-phase

Get Price

6 FAQs about [Inverter output voltage measurement]

How do you test an inverter with a multimeter?

Measure output voltage: After the inverter is powered on, use a multimeter to measure the AC output voltage. It should match the rated output of the inverter (e.g., 120V or 230V, depending on your region). Check waveform with an oscilloscope: Connect an oscilloscope to the output of the inverter to check the waveform.

How do you test a pure sine power inverter?

Battery condition: If testing with a battery, check the battery's voltage and charge level to make sure it is within the optimal range for the pure sine power inverter. Measure output voltage: After the inverter is powered on, use a multimeter to measure the AC output voltage.

How do you test a battery inverter?

Measure input voltage: Use a multimeter to measure the input voltage of the battery or power supply. Make sure it meets the input voltage requirements of the inverter (e.g., 12V, 24V, 48V).

Do you need a volt meter for an inverter?

Consequently, it's necessary to use a true RMS voltmeter (digital multimeter) and current meter (clamp meter). On the secondary side of an inverter, the voltage and current’s fundamental wave includes harmonic components.

What does abnormal inverter voltage mean?

Abnormal inverter voltage may indicate a problem with the inverter's internal circuit. The stability of the voltage is particularly important for the normal operation of the appliance, if the input voltage is too low or too high, the inverter may not work properly, resulting in output instability or failure.

What happens if an inverter detects a fault?

If the inverter detects internal faults or anomalies, such as input voltage, output voltage, temperature, load, current, etc. Once these parameters are detected to be outside the preset safe range, the system triggers an alarm that displays an error code through the display.

More related information

-

New inverter voltage output is low

New inverter voltage output is low

-

Inverter high voltage output

Inverter high voltage output

-

Inverter output voltage is over 1 000 volts

Inverter output voltage is over 1 000 volts

-

110kw photovoltaic inverter output voltage

110kw photovoltaic inverter output voltage

-

Inverter AC output connected to voltage regulator

Inverter AC output connected to voltage regulator

-

Home storage system inverter output voltage

Home storage system inverter output voltage

-

What is the normal output voltage of the inverter

What is the normal output voltage of the inverter

-

Is it normal for the inverter to output 246V AC voltage

Is it normal for the inverter to output 246V AC voltage

Commercial & Industrial Solar Storage Market Growth

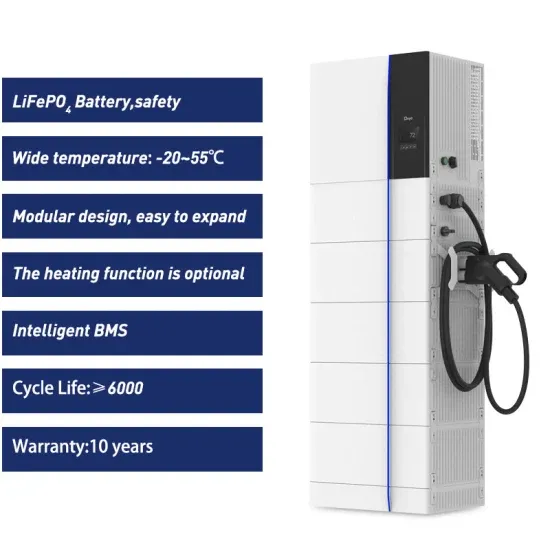

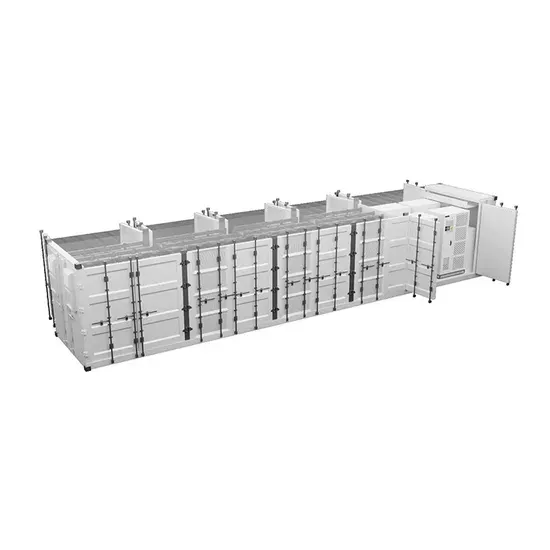

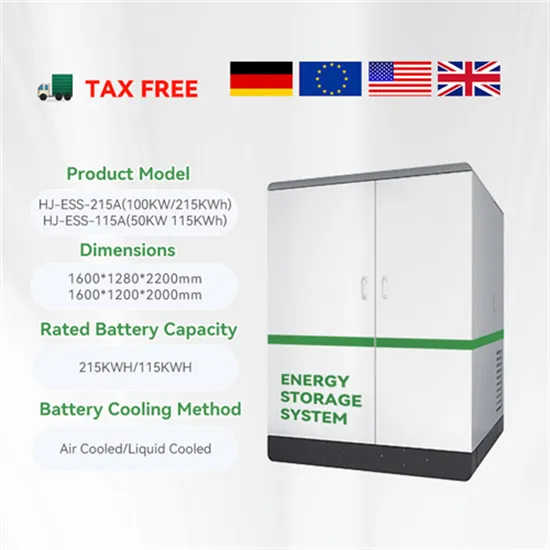

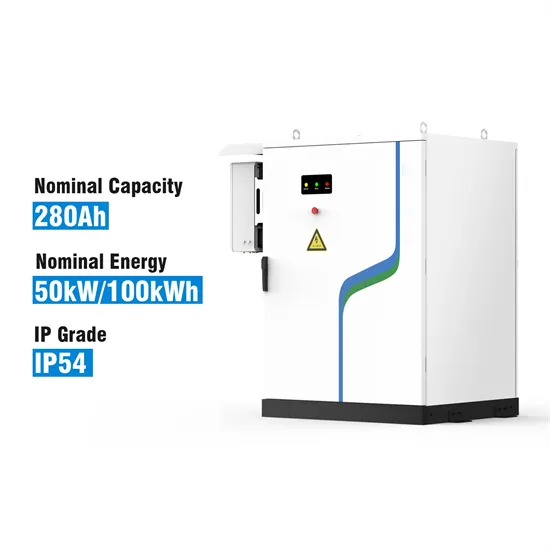

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.