Technical White Paper SolarEdge Single Phase Inverter

Traditional PV inverters have MPPT functions built into the inverter. This means the inverter adjusts its DC input voltage to match that of the PV array connected to it. In this type of

Get Price

Using an Inverting Regulator Buck/Boost Conversion

This article describes the function of a switching inverting regulator and its application and then leads on to describe a topology that uses the

Get Price

Voltage Control Techniques for Inverters | EEEGUIDE

Variable voltage variable frequency supply to the motor is obtained within the Inverter Control itself using suitable control based on the principles of PWM or PSM (phase shift modulation).

Get Price

Using an Inverting Regulator Buck/Boost Conversion | DigiKey

This article describes the function of a switching inverting regulator and its application and then leads on to describe a topology that uses the device to regulate a varying

Get Price

AVR For Generator

An automatic voltage regulator is a solid-state electronic device tasked with maintaining the generator output voltage at a preset value despite variable loads and the

Get Price

INVERTERS

The alternator is a three phase, four pole, star connected ac generator. The dc input is supplied to the generator field coils and connected to ground through a carbon pile voltage regulator. The

Get Price

Voltage regulator

An integrated circuit voltage regulator A voltage regulator is a system designed to automatically maintain a constant voltage. It may use a simple feed-forward

Get Price

Inverter Transformer and its Working Principle

The inverters produce AC by switching the polarity of the DC power source, and almost all industries and residential areas need Alternating

Get Price

Does Your Inverter Require an AVR or a Stabilizer?

An Automatic Voltage Regulator more commonly known as Stabilizer is an electrical appliance that is designed to deliver a constant

Get Price

Three-phase, Three-wire AC Regulator with Balanced

The circuit of a three-phase, three-wire ac regulator (termed as ac to ac voltage converter) with balanced resistive (star-connected) load is shown in Fig.

Get Price

Regulating Voltage: Recommendations for Smart Inverters

This report from GridLab provides an introduction to voltage regulation concepts, including advantages and disadvantages of various control modes. The authors include

Get Price

Phase Locked Loop Control of Inverters in a Microgrid

The - and -voltage components are used by the PLL to estimate the frequency and establish the phase reference for the inverter. These quantities are provided to the phase regulator which

Get Price

Voltage Inverter : Circuit, Working and Its Applications

An inverter is an electrical device, which converts DC power to AC power and either increases or decreases the voltage level accordingly. In comparison, a converter

Get Price

Voltage Control Techniques for Inverters | EEEGUIDE

The Voltage Control Techniques for Inverters can be done in two ways. by varying the dc link voltage by varying the ac voltage at the output using a variable ratio transformer (a) The

Get Price

Voltage Inverter : Circuit, Working and Its Applications

An inverter is an electrical device, which converts DC power to AC power and either increases or decreases the voltage level accordingly. In

Get Price

REGULATING VOLTAGE: RECOMMENDATIONS FOR

Reactive power output is based on the distribution system voltage following a specified volt-var response "curve" which typically would have a deadband around the target voltage where no

Get Price

Step-by-step guide: Connecting an inverter to your house wiring

Learn how to connect an inverter to your house wiring with step-by-step diagrams for a seamless power backup system.

Get Price

Troubleshooting Inverter Problems: A Step-by-Step Guide

Inverters play a crucial role in many modern systems, converting DC power from sources like batteries or solar panels into AC power that can be used by household

Get Price

EE6503 POWER EELCTRONICS AC VOLTAGE

1. Introduction. AC voltage controllers (ac line voltage controllers) are employed to vary the RMS value of the alternating voltage applied to a load circuit.An ac voltage controller is a type of

Get Price

CSM_Inverter_TG_E_1_1

With this method, the inverter monitors the output voltage, the output current, and the encoder feedback from the motor. The encoder feedback is used to adjust the output waveform to

Get Price

Automatic Inverter Output Voltage Correction Circuit

The simple inverter automatic load voltage correction circuit presented below could be effectively used for the proposed application and for regulating the output of an inverter

Get Price

Does Your Inverter Require an AVR or a Stabilizer?

An Automatic Voltage Regulator more commonly known as Stabilizer is an electrical appliance that is designed to deliver a constant voltage to a load at its output

Get Price

Automatic Inverter Output Voltage Correction Circuit

The simple inverter automatic load voltage correction circuit presented below could be effectively used for the proposed application and for

Get Price

Chapter 6: Voltage Regulator

The fixed voltage regulator has an unregulated dc input voltage Vi applied to one input terminal, a regulated output dc voltage Vo from a second terminal, and the third terminal connected to

Get Price

electrical

Can I connect a stabilizer on my inverter so that a continuous voltage of 230V can be supplied to my TV and PS3 and other speakers? During mains on: Mains (160V) > inverter (160V) >

Get Price

Voltage Control Methods of Inverter – PWM Technique

In this method of control, an ac voltage controller is connected at the output of the inverter to obtain the required (controlled) output ac voltage. The block diagram representation

Get Price

6 FAQs about [Inverter AC output connected to voltage regulator]

How to control AC voltage in an inverter?

Basically, there are three techniques by which the voltage can be controlled in an inverter. They are, Internal control of Inverter. In this method of control, an ac voltage controller is connected at the output of the inverter to obtain the required (controlled) output ac voltage.

What is internal control of inverter?

Internal control of Inverter. In this method of control, an ac voltage controller is connected at the output of the inverter to obtain the required (controlled) output ac voltage. The block diagram representation of this method is shown in the below figure.

What is a motor control inverter?

In motor control applications, inverters handle the control of circuit voltage along with frequency so that the saturation of motor magnetic circuits is avoided. In the case of variable speed drives, inverters with voltage control help in achieving voltage variation.

What is voltage control of inverter?

Voltage control of inverters is employed in order to compensate for changes in input dc voltage. Basically, there are three techniques by which the voltage can be controlled in an inverter. They are, Internal control of Inverter.

What do you need to know about input power inverters?

Here are some important specifications that you need to know about input power inverters. Input Voltage: The input voltage supplied from the DC source to the inverter follows the inverter voltage specifications, which start from 12V, 24V, or 48V.

How do inverter circuits work?

In this, the inverter circuit is fed from a constant dc voltage source and a controlled ac voltage is obtained at the output terminals by turning ON and OFF the switching components in the inverter circuit. The main drawback of this method is that it requires very low turn-ON and turn-OFF time thyristors which are very expensive.

More related information

-

What is the output voltage of the battery connected to the inverter

What is the output voltage of the battery connected to the inverter

-

Is it normal for the inverter to output 246V AC voltage

Is it normal for the inverter to output 246V AC voltage

-

What is the maximum output voltage of the inverter

What is the maximum output voltage of the inverter

-

Is the inverter connected to the high voltage positive or negative

Is the inverter connected to the high voltage positive or negative

-

The inverter output voltage is low after rectification

The inverter output voltage is low after rectification

-

Inverter high voltage output

Inverter high voltage output

-

Southern Europe inverter output voltage and frequency

Southern Europe inverter output voltage and frequency

-

Household photovoltaic inverter output voltage

Household photovoltaic inverter output voltage

Commercial & Industrial Solar Storage Market Growth

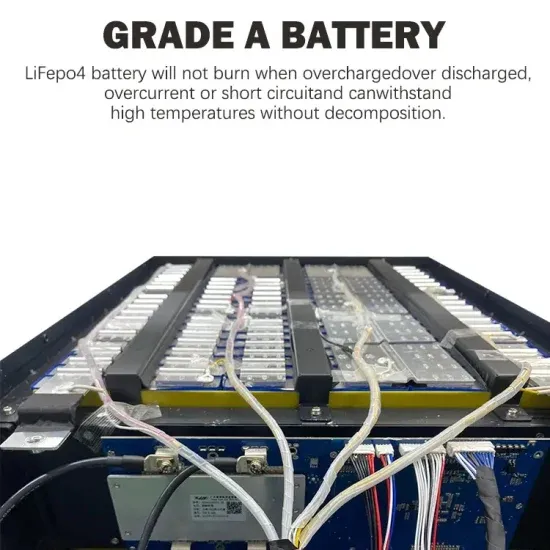

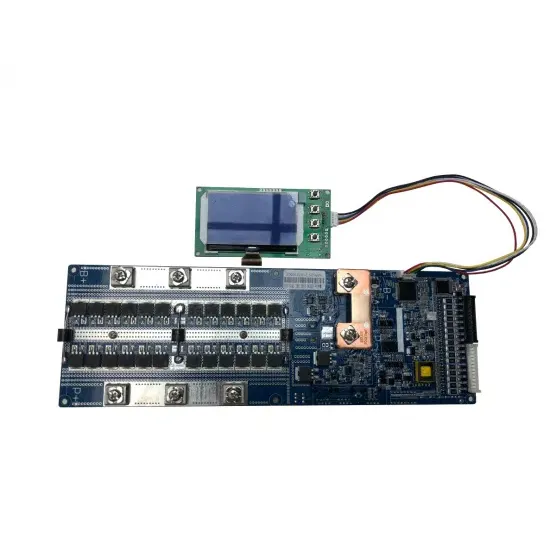

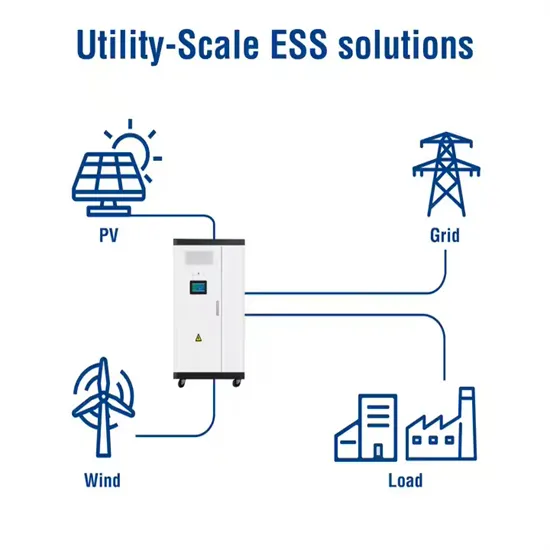

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.