How to Charge and Discharge LiFePO4 Batteries

Learn the best practices for charging and discharging LiFePO4 batteries to extend their lifespan, ensure safety, and optimize performance.

Get Price

High Voltage LiFePO4 Lithium Battery Pack with BMS

High Voltage Lithium batteries are engineered to excel, with a maximum charging current of 25A and a robust discharge current capacity. Connectivity is seamless with CAN and RS485

Get Price

Your Comprehensive Guide to High-Rate Discharge

The high-rate discharge battery is an indispensable power source in today''s rapidly advancing technological landscape. This comprehensive

Get Price

A Guide to Understanding Battery Specifications

Battery Basics Cell, modules, and packs – Hybrid and electric vehicles have a high voltage battery pack that consists of individual modules and cells organized in series and parallel. A cell is the

Get Price

FGCD-K30NT Battery Discharge-Charge Unit

Multi-function: It integrates charging, discharging and cycle test into one unit for solving various maintenance tasks of battery packs. Wide Voltage Range: the

Get Price

Lithium Battery Pack Tester DSF-20

The Lead-Acid & Lithium Battery Series Charge Discharge Tester DSF20 is integrated with the function of a high-precision capacity series discharging test and a high-precision series

Get Price

Power Batteries with LTO technology

Proventia high-voltage battery with separate Battery Management Unit (BMU) and three battery packages of different sizes (with 3, 6 and 7 modules), which can be freely connected in series

Get Price

Battery Charge and Discharge Tester Manufacturer,

Battery Charge and Discharge Tester (1000V1000A ) Product model: WA-BT-1000V1000A Voltage range/channel: 15V~1000V Current range/channel:

Get Price

Lithium Battery Charge Discharge Unit

CP-HK1000 lithium battery charger/discharger adopts advanced bi-directional AC-DC conversion technology with high power and low harmonic characteristics.

Get Price

High Voltage Battery Packs | Bulk High Voltage Lithium-Ion Battery Pack

Order custom high-voltage battery pack manufacturing from Voltaplex. We are your trusted partner for manufacturing the high-voltage lithium-ion batteries your operations need.

Get Price

Discharging

The high discharge power and a voltage range of up to 1000V allow for high-performance discharging. Our operating point optimizer continuously

Get Price

Understanding Charge-Discharge Curves of Li-ion Cells

This charge curve of a Lithium-ion cell plots various parameters such as voltage, charging time, charging current and charged capacity. When the cells are assembled as a

Get Price

1000V Battery Capacitor Fast Discharger High Voltage Discharging

Buy 1000V Battery Capacitor Fast Discharger High Voltage Discharging Tool Electronic Repair Digital Sparkpen Quick Discharge at Walmart

Get Price

FGCD Series High-Voltage Battery Discharge-Charge

The FGCD Series High-Voltage Battery Discharge-Charge Unit offers efficient testing and maintenance for lithium battery packs, supporting high-voltage

Get Price

FGCD-K30NT Battery Discharge-Charge Unit

Multi-function: It integrates charging, discharging and cycle test into one unit for solving various maintenance tasks of battery packs. Wide Voltage Range: the test range covers 200-1000V,

Get Price

High quality lithium battery charging and discharging tester Battery

High quality lithium battery charging and discharging tester Battery pack capacity test equipment manufacturers, You can get more details about High quality lithium battery charging and

Get Price

200kWh-241kWh High Voltage Lithium Battery Energy

Explore the BSLBATT ESS-GRID Cabinet Series, an industrial and commercial energy storage system available in 200kWh, 215kWh, 225kWh, and 245kWh

Get Price

High Voltage Battery Packs | Bulk High Voltage

Order custom high-voltage battery pack manufacturing from Voltaplex. We are your trusted partner for manufacturing the high-voltage lithium-ion batteries

Get Price

Lithium Battery Discharge-Charge Unit

ABE-2550NT Lithium Battery Discharge-Charge Unit $100-1,000 Min. Order: 1 set Intelligent High-Voltage 1000V EV Lithium Battery Discharge Charge Activation Test After-sales Machine

Get Price

ELP400 EV Battery Pack Module Charging and Discharging Device

ELP400 has built-in various test and maintenance modes, which are suitable for the discharge, charging, cycle charging and discharging tests of various lithium batteries on the market.

Get Price

How does a Lithium-ion Battery Charge and Discharge?

Monitoring the charge and discharge cycles of lithium-ion batteries is critical for ensuring their longevity and safety. Overcharging or deep

Get Price

1000V 300A Battry Pack Charge And Discharge High Power

ACEY-RCDS-1000V300A is mainly used for testing the charging and discharging cycle of finished lithium batteries.The equipment has four test steps: charging, discharging, shelving and cycling.

Get Price

Understanding Charge-Discharge Curves of Li-ion Cells

This charge curve of a Lithium-ion cell plots various parameters such as voltage, charging time, charging current and charged capacity. When

Get Price

How Voltage and Discharge Testing Reveals True Battery Capacity

How Voltage and Discharge Testing Reveals True Battery Capacity Voltage testing is the most accessible method for estimating battery capacity, but it only provides a

Get Price

Fully Discharge Lithium Battery: Damage & Prevention

Fully discharging lithium batteries to 0% causes permanent damage. Learn the risks and proper 20-80% charging rule for longer battery life.

Get Price

ELP400 EV Battery Pack Module Charging and

ELP400 has built-in various test and maintenance modes, which are suitable for the discharge, charging, cycle charging and discharging tests of various

Get Price

CTS High-Voltage Lithium Battery Systems for Electric

CTS High-Voltage Lithium Battery Systems deliver reliable power for excavators, tractors, forklifts. IP67-rated, -20°C to 60°C operation, 1C charge/discharge. Trusted by 500+ industrial OEMs.

Get Price

FGCD Series High-Voltage Battery Discharge-Charge Unit

The FGCD Series High-Voltage Battery Discharge-Charge Unit offers efficient testing and maintenance for lithium battery packs, supporting high-voltage discharge, charge, and cycle

Get Price

CTS High-Voltage Lithium Battery Systems for Electric

CTS High-Voltage Lithium Battery Systems deliver reliable power for excavators, tractors, forklifts. IP67-rated, -20°C to 60°C operation, 1C charge/discharge.

Get Price

Battery Cell, Module, and Pack Cycler Test Equipment < Chroma

High precision, integrated battery charge / discharge cycle test systems designed for lithium ion and other chemistries. Advanced features include regenerative discharge systems that

Get Price

6 FAQs about [Lithium battery pack 1000V high voltage charging and discharging]

What is the fgcd series high voltage battery discharge-charge unit?

The FGCD Series High-Voltage Battery Discharge-Charge Unit offers efficient testing and maintenance for lithium battery packs, supporting high-voltage discharge, charge, and cycle tests. It ensures accurate testing with real-time cell voltage monitoring, boosting battery performance and lifespan.

How to charge a lithium ion battery?

When the cells are assembled as a battery pack for an application, they must be charged using a constant current and constant voltage (CC-CV) method. Hence, a CC-CV charger is highly recommended for Lithium-ion batteries. The CC-CV method starts with constant charging while the battery pack’s voltage rises.

Which battery charger is best for lithium ion batteries?

Hence, a CC-CV charger is highly recommended for Lithium-ion batteries. The CC-CV method starts with constant charging while the battery pack’s voltage rises. When the battery reaches its full charge cut-off voltage, constant voltage mode takes over, and there is a drop in the charging current.

What is a flat discharge curve in a lithium ion battery?

The industry standard is to provide 80% fast charge, then the charging current comes down and eventually, trickle charge mode comes in place. This discharge curve of a Lithium-ion cell plots voltage vs discharged capacity. A flat discharge curve is better because it means the voltage is constant throughout the course of battery discharge.

What is the charge curve of a lithium ion cell?

This charge curve of a Lithium-ion cell plots various parameters such as voltage, charging time, charging current and charged capacity. When the cells are assembled as a battery pack for an application, they must be charged using a constant current and constant voltage (CC-CV) method.

What temperature can a lithium ion cell charge and discharge?

Lithium-ion cells can charge between 0°C and 60°C and can discharge between -20°C and 60°C. A standard operating temperature of 25±2°C during charge and discharge allows for the performance of the cell as per its datasheet.

More related information

-

380v high voltage lithium battery pack

380v high voltage lithium battery pack

-

What is the charging voltage of a 7 2v lithium battery pack

What is the charging voltage of a 7 2v lithium battery pack

-

48v lithium battery pack voltage

48v lithium battery pack voltage

-

Lithium battery pack charging and power off

Lithium battery pack charging and power off

-

High voltage inverter charging and discharging

High voltage inverter charging and discharging

-

12v high current lithium battery pack

12v high current lithium battery pack

-

Single charging of a series lithium battery pack

Single charging of a series lithium battery pack

-

Lithium battery pack voltage standard

Lithium battery pack voltage standard

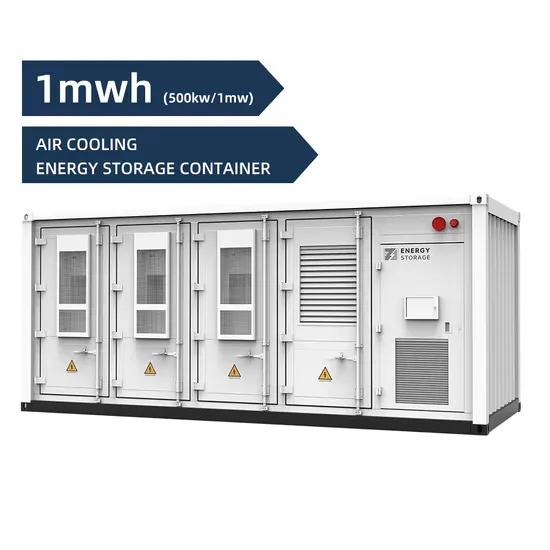

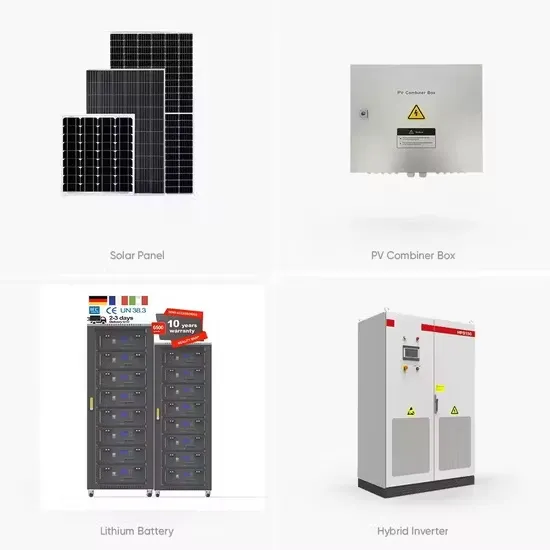

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

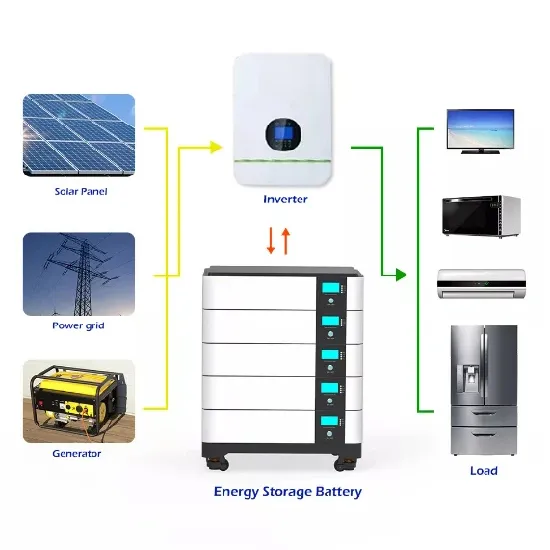

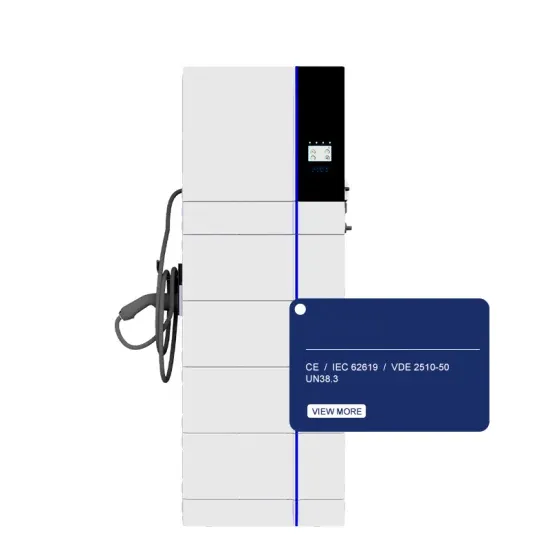

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.