Design and analysis of a high-efficiency bi-directional DAB

Achieving an efficient EV battery charger necessitates the implementation of a proficient charging algorithm and a high-power converter capable of adeptly regulating battery

Get Price

Can BMS Charging and Discharging Simultaneously?

CC-CV charging systematically optimizes both the initial rapid charging stage and the controlled voltage stage, thereby maximizing overall

Get Price

Best charge settings for Pylontech

It also seems that the inverter will stop charging as soon as the battery reaches the "stop charging voltage" and will not resume charging

Get Price

A 13-level switched-capacitor-based multilevel inverter with

Compared to other 13-level switched-capacitor inverters, the proposed structure utilizes fewer components, capacitors with lower maximum voltage, and fewer conduction

Get Price

Understanding How an Inverter Charger Charges

During the initial phase of battery charging, the inverter charger operates in the bulk charging mode. It supplies a high current at a constant

Get Price

Deye SUN-(5-25)K-SG01HP3-EU Three Phase Hybrid

Discover Deye''s SUN- (5-25)K-SG01HP3-EU Three Phase Hybrid Inverters, featuring high efficiency, diesel generator support, and scalability up

Get Price

A DC-Link Hybrid Active Discharge Scheme for Traction Inverters

This paper examines the limitations of traditional discharge techniques and proposes a novel hybrid discharge solution that combines the existing winding-based

Get Price

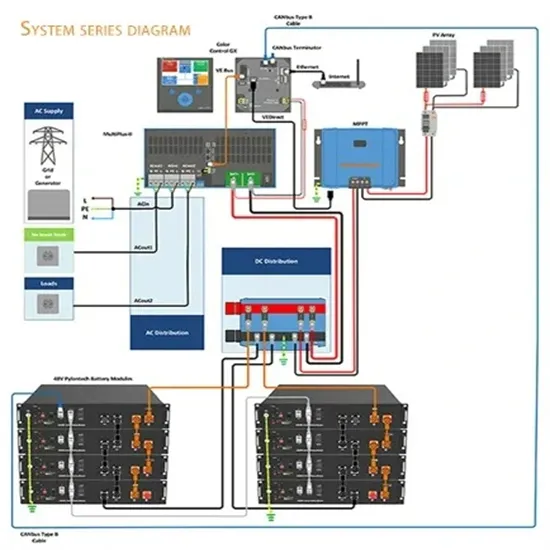

2MW_PCS_BESS2010 dd

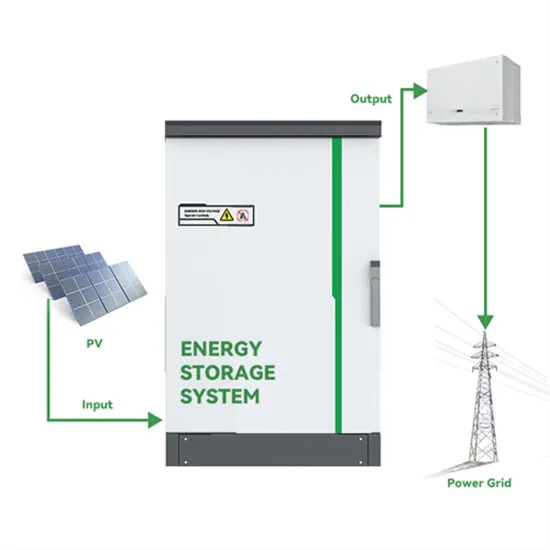

The PCS is capable of taking power from the utility grid and converting it to DC power for charging the battery as well as taking power from the battery (discharging) and sending it back to the

Get Price

Webinar: Active discharge and pre-charge of EV high-voltage

In addition to a pre-charge circuit between the battery and the high-voltage bus that limits the inrush current when starting or charging the vehicle, the PDU is required to include an

Get Price

Understanding BESS: MW, MWh, and Charging/Discharging

A well-designed BESS balances both parameters to meet specific operational needs—be it short-term high-power delivery or long-duration energy supply.

Get Price

Dyness B3 modules: high charge/discharge current

What you would need to investigate imusing the vrm is if there really is a high charge and discharge current there. Is the charge going above what the battery is requesting

Get Price

Advanced Control Strategy for Solar PV and Battery Storage

It also has the capability of MPPT. The proposed control topology can generate the correct AC voltage under unbalanced DC voltage conditions by using a vector modulation technique. It

Get Price

Optimal DOD (Depth of Discharge) and SOC (State of

Stressing of graphite at full charge, and lithium metal creation near negative anode at very deep discharge are the two most damaging abuse

Get Price

High-voltage discharge system of EV – CMVTE

Its core purpose is to prevent the risk of electric shock and secondary hazards caused by residual voltage in the high-voltage system, and

Get Price

Why Pre-Charge Circuits are Necessary in High-Voltage

High-voltage systems (100V+) often use precharged circuits to limit inrush current. This process protects the system from damage, extends lifespan, and increases reliability.

Get Price

Designing a high voltage DC-link capacitor active precharge circuit

A straightforward approach to designing an efficient, active pre-charge circuit using a spreadsheet calculator.

Get Price

Enabling Smarter DC Link Discharge in EV Traction Inverters

High-voltage DC links are central to a wide range of power electronic systems in electric and hybrid vehicles—including inverters relying on large capacitors (e.g 1 mF) to

Get Price

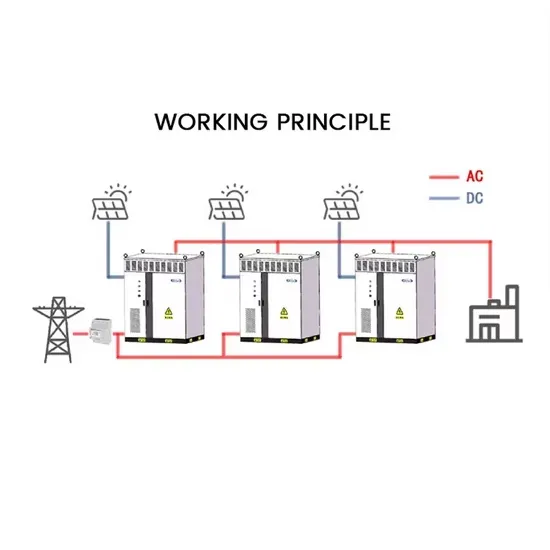

The working principle of bidirectional charging and discharging

Bidirectional AC-DC converters offer several advantages, including high energy conversion efficiency, high power density, compact size, and low harmonic content, minimizing

Get Price

How to Reduce the Power Resistor for DC-Link Discharge in

The DC-Link capacitor is a part of every traction inverter and is positioned in parallel with the high-voltage battery and the power stage (see Figure 1). The DC-Link capacitor has several

Get Price

A DC-Link Hybrid Active Discharge Scheme for

This paper examines the limitations of traditional discharge techniques and proposes a novel hybrid discharge solution that combines the

Get Price

Help finding a circuit for discharging a high voltage capacitor

The inverter has a capacitance that, by the competition rules, we need to discharge when we shutdown the car. For this, we use a 4.7 kΩ power resistor. I''m in charge

Get Price

Single-Phase, Bidirectional, 7.7 kW Totem Pole On

In G2V mode, the proposed infrastructure consists of an on-board, single-phase, 7.7 kW totem pole converter in continuous conduction mode to

Get Price

High-voltage discharge system of EV – CMVTE

Its core purpose is to prevent the risk of electric shock and secondary hazards caused by residual voltage in the high-voltage system, and to ensure the safety of personnel in

Get Price

The working principle of bidirectional charging and

Bidirectional AC-DC converters offer several advantages, including high energy conversion efficiency, high power density, compact size,

Get Price

Active Discharge and Pre-charge of EV High Voltage Power

RELAY 1 prevents leakage current in Disconnect Mode. SW1 is used to detect SHORT circuit on HV DC Bus. Capacitor is charging thru SW1 that is activated by MCU. When the HV DC Bus is

Get Price

Enabling Smarter DC Link Discharge in EV Traction

High-voltage DC links are central to a wide range of power electronic systems in electric and hybrid vehicles—including inverters relying

Get Price

DC bus pre-charging techniques

This application note presents a technique for pre-charging the DC bus of a grid-tie inverter from the AC side. This technique is commonly used in

Get Price

Understanding How an Inverter Charger Charges Your Battery –

During the initial phase of battery charging, the inverter charger operates in the bulk charging mode. It supplies a high current at a constant voltage, allowing the battery to charge

Get Price

Designing a high voltage DC-link capacitor active

A straightforward approach to designing an efficient, active pre-charge circuit using a spreadsheet calculator.

Get Price

High Voltage Power Supply Output Fall & Discharge Times

This multiplier circuit (an arrangement of capacitors and diodes) uses the principle of charging and discharging capacitors on alternate half cycles of the AC voltage, where the output is the sum

Get Price

6 FAQs about [High voltage inverter charging and discharging]

What is high-voltage active discharge?

High-voltage active discharge refers to the process in which the electric energy in the high-voltage capacitor is quickly (generally 1 ~ 2 s) released to a safe level (the high voltage is reduced to below 60 V) through a special discharge circuit and control strategy after the high-voltage system of the EV is powered off.

What is a high-voltage DC link?

Image used courtesy of Adobe Stock High-voltage DC links are central to a wide range of power electronic systems in electric and hybrid vehicles—including inverters relying on large capacitors (e.g 1 mF) to stabilize the voltage, reduce ripple, and support efficient control and operation.

Why is high-voltage active discharge important in EV safety design?

If there is no effective discharge mechanism, the residual voltage may cause electric shock accidents, and even lead to serious consequences such as fire. Therefore, the high-voltage active discharge function becomes an indispensable part of the EV safety design.

Why is high voltage active discharge important?

Therefore, the high-voltage active discharge function becomes an indispensable part of the EV safety design. These risks can be avoided by actively discharging the system voltage to a safe level quickly. Considering personal safety, there are clear requirements for the high voltage safety of EV at the standard level.

What does an inverter charger do?

It regulates the voltage and frequency of the AC power, ensuring compatibility with standard electrical devices and appliances. The charger component of an inverter charger is responsible for replenishing the battery bank's energy. It converts AC electricity from the grid or a generator into DC power and supplies it to the batteries.

What is a pre-charge initial state in a high voltage system?

Figure 1. Pre-charge Initial State In a high voltage system, a typical block diagram may consist of two high current contactors with a separate pre-charge contactor, and a DC link capacitor in parallel with a load (for example, traction inverter).

More related information

-

Lithium battery pack 1000V high voltage charging and discharging

Lithium battery pack 1000V high voltage charging and discharging

-

High voltage 500kv inverter

High voltage 500kv inverter

-

High voltage inverter maximum output current

High voltage inverter maximum output current

-

High voltage inverter outdoor

High voltage inverter outdoor

-

Weak current to high voltage inverter

Weak current to high voltage inverter

-

24v inverter voltage is too high

24v inverter voltage is too high

-

What is a new energy high voltage inverter

What is a new energy high voltage inverter

-

Brazil high voltage inverter

Brazil high voltage inverter

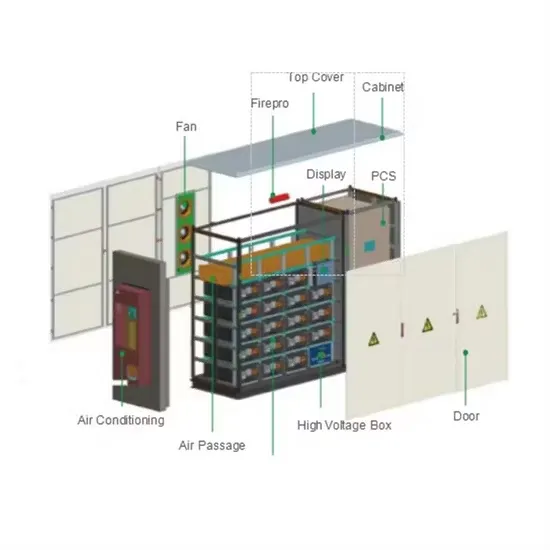

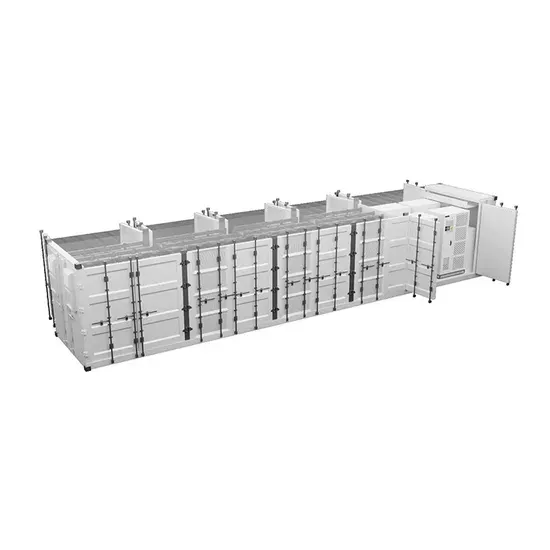

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

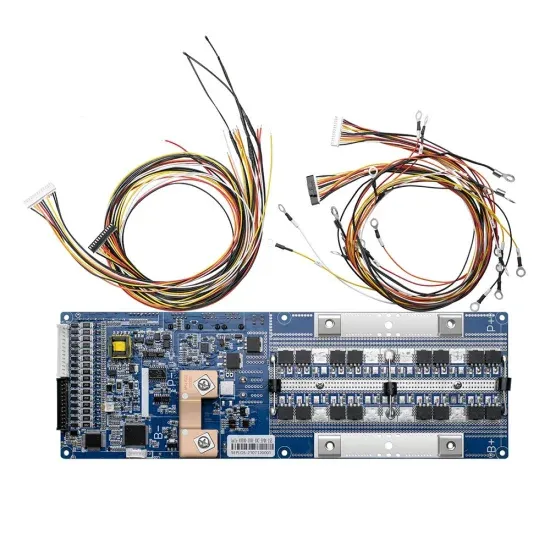

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.