Commissioning an Individual Battery Cabinet

Performing the next step depends on whether the DHCP protocol for the inverter''s battery communication interface is enabled or disabled. If the DHCP protocol is disabled on the

Get Price

08.30.23

The document outlines the commissioning process for a battery energy storage system (BESS). It involves extensive testing and verification of the BESS components,

Get Price

UPS Installation Testing and Commissioning Method

The purpose of this method statement is to define the procedure for Installation, Testing and Commissioning of UPS. Also to ensure that agreed

Get Price

Arlington Battery Energy Storage System

1.4 Commissioning Process During construction, the CxA will generate the commissioning plan which will provide direction for the commissioning process. Due to the

Get Price

Battery Energy Storage System (BESS)

The commissioning process is usually completed with a series of capacity and performance tests that have been approved for the project by the utility, the

Get Price

Battery Energy Storage Testing

Quanta Technology provides services for the development and implementation of BESS installations, including commissioning and testing services. Our experts

Get Price

Battery Energy Storage System (BESS) Commissioning:

The commissioning process is usually completed with a series of capacity and performance tests that have been approved for the project by the utility, the project owner and IHI Terrasun.

Get Price

METHOD STATEMENT FOR PRECOMMISSIONING

Ensure that the Central Battery panels & Substation panels installation are complete and mechanical completion is approved & all comments on the

Get Price

Battery Room Ventilation and Safety

BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms must be adequately

Get Price

Battery Rack | Battery Cabinets | Cabinet Rack for UPS

External Battery Racks and Cabinets for Storing Batteries Our External Battery Racks and Cabinet design encasing solutions are a premium brand that offer

Get Price

How to calculate battery room hydrogen ventilation requirements

How to calculate hydrogen ventilation requirements for battery rooms.For standby DC power systems or AC UPS systems, battery room ventilation is calculated in accordance to EN 50272

Get Price

Battery System Start-Up and Commissioning Procedure

Starting up and commissioning a battery system is a crucial process to ensure the reliable and efficient operation of the batteries. In this section, we will discuss the essential

Get Price

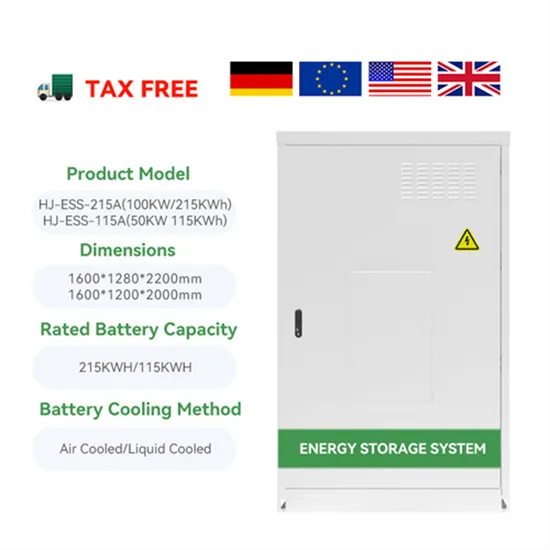

What is the size of a standard battery cabinet

The size of the battery terminal depends on the battery''''s size and type, and it can vary from a few millimeters to several centimeters. What size are battery terminals? Battery terminals are

Get Price

Proper Commissioning Procedures for Lead-Acid Batteries

New system commissioning must be carried out properly and documented for the record. This paper will explore typical commissioning procedures for both, vented lead-acid (VLA) and

Get Price

Battery Cabinets & Racks

ANCILLARY PRODUCTS Battery Cabinets & Racks Eram Power Electronics Company designs and builds custom DC enclosures for battery systems and/or chargers. A typical cabinet

Get Price

Commissioning of BESS

Do we know what tests to run and what the results should be? Operating Specifications — Parameters that the system should operate within. Do the Individual components of the

Get Price

Generator Commissioning: Step-by-Step Procedure

A properly commissioned generator minimizes the risk of electrical faults, mechanical failures, and operational inefficiencies. This blog outlines the step

Get Price

Battery Energy Storage System (BESS)

During energy storage project commissioning, every team involved feels the heat: For the EPC (Engineering Procurement and Construction) team, it''s their final

Get Price

STANDARD FOR ELECTRICAL COMMISSIONING

The ANSI/NETA Standard for Electrical Commissioning Specifications for Electrical Power Equipment and Systems is the most current revision of this document and was approved as an

Get Price

Lithium-ion Battery Storage Technical Specifications

Battery pack performance warranty for at least 10 years after the date of successful completion of commissioning. Battery pack shall retain at least 70% of nominal energy capacity for the

Get Price

Eaton s lithium-ion UPS battery Q&A

This document will serve as a guide for Eaton salespersons, sales support personnel, engineering clients, and end users who have questions regarding the lithium battery cabinets used with

Get Price

Pixii Home Outdoor Cabinet Commissioning Manual

View and Download Pixii Home Outdoor Cabinet commissioning manual online. Grid tied energy storage system. Home Outdoor Cabinet storage pdf manual download.

Get Price

The BESS System: Construction, Commissioning, and O&M Guide

A comprehensive guide on the construction, commissioning, and operation & maintenance of industrial and commercial energy storage systems.

Get Price

VRLA Installation and Commissioning

IEEE Standard 1187 establishes the recommended practices for the design and installation of valve-regulated lead-acid (VRLA) batteries.

Get Price

METHOD STATEMENT FOR PRECOMMISSIONING & COMMISSIONING OF

Ensure that the Central Battery panels & Substation panels installation are complete and mechanical completion is approved & all comments on the installation inspections are

Get Price

6 FAQs about [What is the standard for battery cabinet commissioning ]

What is the commissioning process for a battery energy storage system?

The document outlines the commissioning process for a battery energy storage system (BESS). It involves extensive testing and verification of the BESS components, functions, safety mechanisms, grid integration, and performance to ensure it operates as intended before being approved for operation.

Why do lead-acid batteries need a commissioning charge?

Basically, for all lead-acid batteries, the rate of self discharge increases with storage temperature. The total charge lost is a function of the time in storage at a given temperature. The primary purpose of the commissioning charge is to make sure a new battery is fully charged before it is placed into operational service.

What is the pre-commissioning procedure for central battery system?

Pre-Commissioning Procedure for Central Battery System Ensure that the Central Battery panels & Substation panels installation are complete and mechanical completion is approved & all comments on the installation inspections are incorporated. Ensure that no damage to panels & batteries has occurred between mechanical completion & pre-commissioning.

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

Do VLA batteries require a commissioning charge?

Some VRLA batteries do not require a commissioning charge if they have been installed and are ready to be placed in service shortly after receipt. This may also be the case for some VLA batteries. The maximum time is frequently specified by the battery manufacturer.

What is a commissioning charge?

The total charge lost is a function of the time in storage at a given temperature. The primary purpose of the commissioning charge is to make sure a new battery is fully charged before it is placed into operational service. Noteworthy is the fact that if an acceptance (capacity) test is to be performed, it is vital the battery is up to the task.

More related information

-

What is the input voltage of the battery cabinet

What is the input voltage of the battery cabinet

-

What is the price of outdoor communication battery cabinet in Vanuatu

What is the price of outdoor communication battery cabinet in Vanuatu

-

US standard outdoor battery cabinet to 220V

US standard outdoor battery cabinet to 220V

-

What is the principle of lithium battery energy storage cabinet

What is the principle of lithium battery energy storage cabinet

-

What to do if the battery in the energy storage cabinet becomes hot

What to do if the battery in the energy storage cabinet becomes hot

-

What is the maximum power of the new energy battery cabinet

What is the maximum power of the new energy battery cabinet

-

What type of technology is the battery cabinet base station power

What type of technology is the battery cabinet base station power

-

Energy storage cabinet commissioning price standard

Energy storage cabinet commissioning price standard

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.