UBC87 Battery Cabinet Installation, Operation,

Isolates the battery cabinet from the UPS Divides the 480VDC battery string into two (2) battery strings of 240VDC each. Unlocks the battery cabinet doors to allow access to the cabinet

Get Price

Understanding Input Voltage and Wide Input Voltage

What is Input Voltage? Input voltage refers to the electrical potential difference supplied to a device, circuit, or system to enable its

Get Price

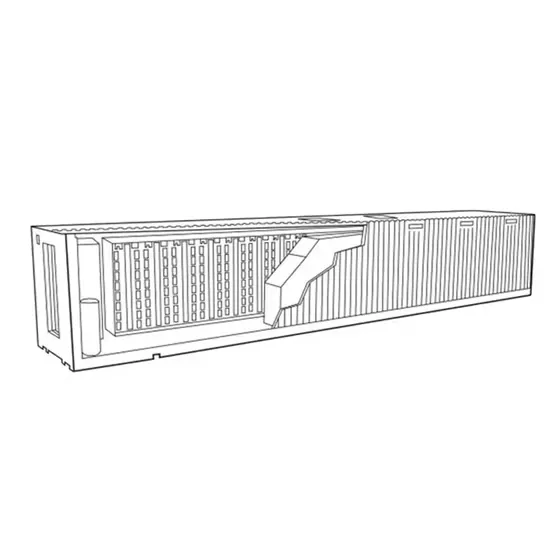

Utility-scale battery energy storage system (BESS)

BESS design IEC - 4.0 MWh system design — How should system designers lay out low-voltage power distribution and conversion for a battery energy storage system (BESS)? In this white

Get Price

VertivTM Liebert® EXM Distribution Cabinet Guide

1.1 Summary These specifications describe requirements for a distribution cabinet, supplying power to sensitive electronic loads. The specified center shall have the ability to provide

Get Price

Eaton 93PM Integrated Battery Cabinet-Large and Large

The battery cabinet contains its own energy source. The internal wiring and output terminals may carry live voltage even when the UPS is not connected to an AC source.

Get Price

Microsoft Word

Also, it monitors the battery compartment temperature – using the built-in sensor – the battery fuse – with a fuse monitoring input – and the battery current – via a current sense input.

Get Price

BATTERY CABINET

An existing PWRcell Battery Cabinet can be upgraded with additional modules. Use the graphic below and the chart on the back of this sheet to understand what components you need for

Get Price

How many volts is the energy storage battery cabinet?

The voltage of energy storage battery cabinets can vary widely. 48V, 120V, 240V, and up to 800V are some common benchmarks. Each voltage level is tailored to different

Get Price

What is the voltage of the energy storage battery cabinet?

The voltage of energy storage battery cabinets typically ranges from 12V to 800V, influenced by application requirements, technology used, and the configuration of battery cells.

Get Price

Power Storage Battery Cabinet Voltage: The Backbone of

Let''s face it – when was the last time you thought about the voltage in your phone''s battery? Probably when it died during that important Zoom call. Now imagine scaling that frustration to

Get Price

Eaton 93PM Integrated Battery Cabinet-Large and Large

The battery wiring used between the battery and the UPS for standalone installations should be a maximum of 20 meters (65 feet) with a voltage drop of less than 1% of nominal DC voltage at

Get Price

UPS Selection Factors for a Control System

Manual Bypass Switch: used to isolate any static transfer switch for maintenance or repair without interruption to UPS. Battery Banks: When input

Get Price

SmartGen HBMS100 Energy storage Battery cabinet

The HBMU100 battery box and HBCU100 master control box communicate with each other via CANBUS. The HBMS100 battery box collects the voltage and

Get Price

Galaxy VX

The 1250 kW I/O cabinet is used for UPS systems from a minimum configuration of 500 kW with two power cabinets to a maximum configuration of 1250 kW N+1 with six power cabinets. The

Get Price

A Guide to Understanding Battery Storage Specifications

Battery Cabinet: A battery cabinet serves as a protective and organized enclosure for housing multiple battery modules within an energy storage system. Its primary purpose is to provide a

Get Price

SmartGen HBMS100 Energy storage Battery cabinet

The HBMU100 battery box and HBCU100 master control box communicate with each other via CANBUS. The HBMS100 battery box collects the voltage and temperature of the single cell

Get Price

Energy storage systems–NEC Article 706

Energy storage system modules, battery cabinets, racks, or trays are permitted to contact adjacent walls or structures, provided that the battery

Get Price

Understanding Battery Input Output: A Comprehensive Guide

Learn about battery input and output, the process of charging and discharging batteries, electric energy input and output, and how batteries power various devices.

Get Price

Eaton-Battery-Handbook-BAT11LTA.PDF

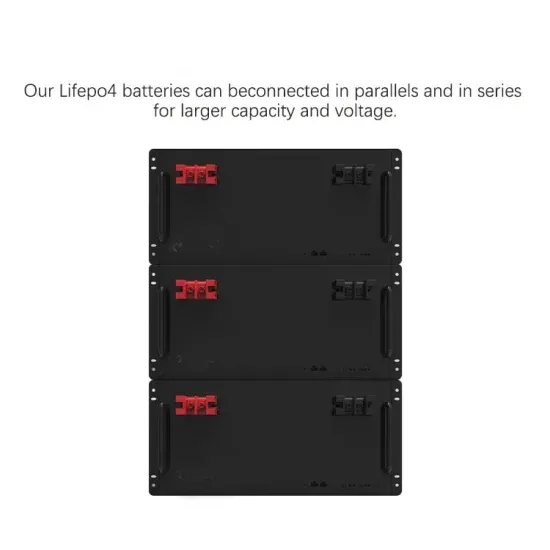

Connecting of the positive terminal of a cell/battery to the negative terminal of the next cell/battery increases the voltage of the battery network while keeping the capacity constant.

Get Price

Battery cabinet voltage of outdoor power supply

Output power kVA: 144 W Input voltage: 90 V - 264 V Output voltage: 24 V Outdoor AC/DC power supply with UPS (24VDC). Protection class IP65 / LiFePO4 battery technology is optimised for

Get Price

SmartGen HBMS100 Energy storage Battery cabinet

Charging Voltage 759.2 V Recommended Backup Time 60 min Cycle Index >2000 Communication Mode RS485/CAN/ETHERNET Product Overview: HBMS100 Energy storage

Get Price

Battery cabinet voltage of outdoor power supply

ZXDUPA-WR12 Outdoor Power Cabinet Product Description Product features. Wide Range of Input Voltage. 85V~300V wide input voltage, high adaptive to poor grid to protect battery. 02.

Get Price

UPS WITH A BATTERY SYSTEM 101. EDUCATION FOR

Generally when an end user decides it is time for a UPS with a battery system, the basic questions are asked: • What AC voltage is required (input / output)? • What is the present load

Get Price

Battery cabinet UPS

The battery cabinets are available in 5 different mechanical dimensions, are able to contain various combination of Batteries, up to maximum 63 blocks, connected in series and parallel,

Get Price

6 FAQs about [What is the input voltage of the battery cabinet ]

How many batteries can a battery cabinet hold?

4Ah to 105Ah (C10).The battery cabinets are available in 5 different mechanical dimensions, are able to contain various combination of Batteries, up to maximum 63 blocks, connected in series and parallel, with positive, negative and middle point poles and with max D tery Capacit (Ah)St dard IEC-EN 62040-1in the cabinet are included Fuse Hold

Can a battery cabinet be connected to a DC Circuit?

The battery cabinet frame is not referenced to the DC circuit. Each battery cabinet has its own overcurrent protection device. Internal battery strings are to be connected by an authorized Eaton Customer Service Engineer. 1.7 For More Information for UPS cabinet conduit and terminal specifications and locations.

Where is the battery cabinet located?

The battery cabinet may be located to either the right or left of the UPS cabinet. The recommended location is to the right of the UPS cabinet. This procedure assumes the battery cabinet is located to the right of the UPS cabinet. 21.

What temperature is a battery cabinet rated for?

The battery cabinet is rated for operation in up to a 40°C (104°F) ambient temperature. NOTE Emergency lighting and power equipment battery cabinets (UL924) are rated for operation in a 20°–30°C (68°–86°F) temperature environment. The batteries are rated for a 25°C (77°F) ambient temperature to extend their useful life.

How many 93pm battery cabinets can a UPS system use?

The UPS system has been evaluated for use with a maximum of four 93PM Battery Cabinets. Use of any other configuration may result in fire, death, and voiding of the warranty. Disconnect the charging source prior to connecting or disconnecting battery terminals. Determine if the battery is inadvertently grounded.

Are battery cabinets 5 & 8 Wired the same?

Battery cabinets 5 through 8 are wired the same. The components inside the IBC are secured to a sturdy metal frame. All repairable parts and assemblies are located for easy removal, with very little disassembly. This design allows authorized service personnel to perform routine maintenance and servicing quickly.

More related information

-

What is the total voltage of the new energy battery cabinet

What is the total voltage of the new energy battery cabinet

-

What is the maximum power of the energy storage cabinet battery

What is the maximum power of the energy storage cabinet battery

-

What to do if the battery cabinet current exceeds the limit

What to do if the battery cabinet current exceeds the limit

-

What is the formula for calculating battery cabinet power

What is the formula for calculating battery cabinet power

-

What is the inverter input voltage

What is the inverter input voltage

-

Battery cabinet in low voltage distribution room

Battery cabinet in low voltage distribution room

-

How much current and voltage does the battery cabinet have

How much current and voltage does the battery cabinet have

-

Battery cabinet voltage shows 0

Battery cabinet voltage shows 0

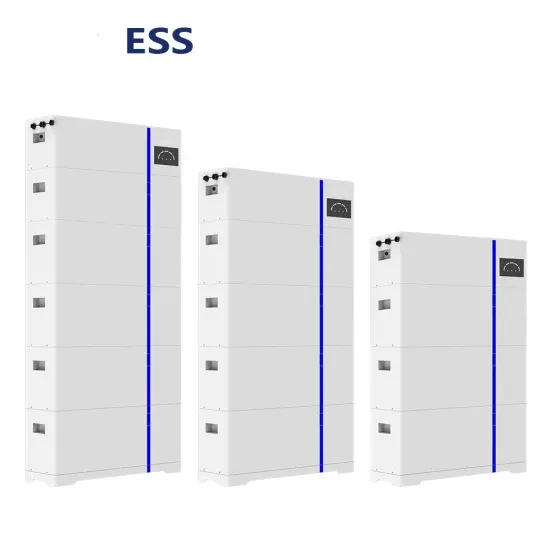

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.