Do EVs that use more that one motor require multiple inverters?

For synchronous motors, the inverter signal needs to be synchronized with the position of the motor, so trying to run multiple PMAC or reluctance motors off the output of one inverter would

Get Price

Is it possible for a single-phase motor to operate without an inverter

A single-phase motor does not require an inverter because it is its intended to run directly on single-phase alternating current. However, using an inverter can have some

Get Price

How to connect a single-phase motor to the inverter

Therefore it is important to sizing the inverter size also on this factor: it must guarantee a supply of current to overcoming the inertia when the motor is started. For this reason, Nastec doesn''t

Get Price

Is There a Motor That Can Be Controlled by an Inverter?

Here''s a video of a conveyor running on a motor controlled by an inverter. Be aware of the link between the conveyor and the characteristics diagram, and examine it.

Get Price

How Variable Frequency Drive 1 Phase to 3 Phase

Mingch''s MC9001 VFD for Single-Phase to Three-Phase Conversion The Mingch MC9001 series inverter is an ideal choice for those

Get Price

Can I use an inverter with a single phase motor? | 999 Automation

It depends who''s asking, and what the application is, but generally speaking the answer is no. Most inverter drives are designed for use with three phase motors. If you have a

Get Price

Making Three-Phase Machines Work in a One-Phase Shop

An electronic inverter transforms single-phase power into direct current and then uses microchip-guided controls to simulate three-phase alternating current. The electronics in

Get Price

How to connect a single-phase motor to the inverter

Special design: there exist in the market inverters designed specifically for single-phase motors, which are optimized in terms of internal circuitry and control algorithms to adapt to the

Get Price

Can an inverter be used to drive a single-phase motor or use a single

Special design: there exist in the market inverters designed specifically for single-phase motors, which are optimized in terms of internal circuitry and control algorithms to adapt to the

Get Price

Is it possible for a single-phase motor to operate

A single-phase motor does not require an inverter because it is its intended to run directly on single-phase alternating current. However, using an

Get Price

Can I run motor with inverter?

No, a single-phase motor cannot be used. In addition, if the Inverter is connected to a split-phase-start induction motor or repulsion-start induction motor, the motor''s internal

Get Price

Can/Should DC-AC Inverter Be Used To Power Inductive Loads (AC Motor)?

While motors present some challenges compared to eg purely resistive loads, they are not especially difficult to drive and it is common to use inverters for this purpose where the

Get Price

Connecting single-phase inverter switches

This assembly is often used in low power inverter systems when the control is done by switch, also widely used for the conversion of three-phase systems into single

Get Price

FAQ: Can I connect a single-phase inverter to a three-phase panel?

Since most string inverters back then were single phase (sometimes referred to as split phase, meaning they had 2 hots, a neutral and ground), and most commercial buildings are three

Get Price

VFD''S for Single Phase Motors?

At points where three-phase power is unavailable or impractical, correctly fitted single-phase motors can potentially be a great option. It is

Get Price

[How do I?]

A typical use for higher h.p. single phase VFD''s is for fan motors and fans or blowers characteristically require a low low speed torque so there is some concern whether

Get Price

Unlocking the Power: Single Phase to Three Phase Inverters

Many applications require three-phase power for optimal operation, yet single-phase power sources are often more readily available. This guide delves into the intricacies of

Get Price

Can single-phase and three-phase inverters be connected together

In industrial, commercial, and civil systems, the vast majority are TN systems. When a grid-connected inverter is connected to the power grid, a three-phase inverter has 3 live wires, 1

Get Price

Can A Single-Phase Inverter Be Used For A Three

When considering solar energy solutions, one common questin arises: can a single-phase inverter be used for a three-phase load? Understanding the

Get Price

motor load on inverters

An inductive load has a very high inrush current, many times that of the nominal. For example, depending on the motor and load, a 1000W

Get Price

Connecting single-phase inverter switches

This assembly is often used in low power inverter systems when the control is done by switch, also widely used for the conversion of three

Get Price

VFD''S for Single Phase Motors?

At points where three-phase power is unavailable or impractical, correctly fitted single-phase motors can potentially be a great option. It is important to note that while using

Get Price

Inverter to Motor Wiring

Our range of STANDARD INVERTERS are designed as a motor control and you should always connect the output direct to a motor.. DO put a three phase motor directly on the u, v and w

Get Price

AC Induction motor start with inverter | Eng-Tips

It is possible that the inverter will current limit at 19 amps and the reduced voltage on the output may be sufficient to start the motor, but probably not, plus there would be a

Get Price

VFDs for Single-Phase Applications

Learn how single-phase VFDs optimize motor performance and save energy. Explore common applications and expert tips for choosing the

Get Price

Detail

Also important is that the motor has the ability to cool itself adequately to prevent damage. Permanent magnet synchronous motors and brushless DC motors inherently

Get Price

Single Phase Motor Inverter Circuit Diagram

In the modern world, a single-phase motor inverter circuit diagram is an essential element of any electrical system used in homes or businesses.

Get Price

Single-phase to 3-phase conversion

You may want to also add that almost any inverter can be used as a single-phase to three-phase converter if you derate the inverter to 67% of its nominal rating. The derating is required

Get Price

6 FAQs about [Can single-phase motors be used with inverters ]

Should I use a single phase motor?

At points where three-phase power is unavailable or impractical, correctly fitted single-phase motors can potentially be a great option. It is important to note that while using single phase output, your motor may run hot at full load and may need to be de-rated.

Can I drive a single phase motor without modification?

If you just want to drive the motor, I think it might be easier to use one of the 3 phase legs from your inverter to drive the single-phase motor without modification. Obviously, check the voltage first. Some larger motors only use the capacitor for starting.

How much power does a single phase inverter use?

The single-phase inverter was powered by a 350V dc voltage supply. The rated apparent power of the inverter is 6.5 kVA. The switching frequency is 10 kHz and the system frequency is 50 Hz. The rated load voltage is 230 V and the rated peak current is chosen as 40 A.

How do you drive a small induction motor with a 3 phase inverter?

I like to drive a small (150W) single phase induction motor by an existing three phase inverter by removing the capacitor and just connecting the two windings to the inverter in an incomplete triangle circuit. I've done that with very small (15W) motors before, which run well, despite a little bit more noisey at low frequencys.

Does a single phase motor need to be de-rated?

It is important to note that while using single phase output, your motor may run hot at full load and may need to be de-rated. “Though they lack the higher efficiencies of their three-phase siblings, single-phase motors – correctly sized and rated – can last a lifetime with little maintenance” (Kevin Heinecke, Leeson Electric).

Are single-phase input drives compatible?

Single-phase input drives are typically horsepower (output amps) limited and have very specific compatibility options when it comes to pairing with different types of single-phase motors. Here’s the list of what motor applications would be considered compatible/incompatible with single-phase designed drives:

More related information

-

Two high voltage inverters can be used in series

Two high voltage inverters can be used in series

-

Can silicon energy batteries be used with inverters

Can silicon energy batteries be used with inverters

-

Are photovoltaic inverters used frequently

Are photovoltaic inverters used frequently

-

The most commonly used voltage for inverters

The most commonly used voltage for inverters

-

Types of motors used for flywheel energy storage

Types of motors used for flywheel energy storage

-

Can a single-phase inverter be used as a single-phase

Can a single-phase inverter be used as a single-phase

-

What batteries are used for sine wave inverters

What batteries are used for sine wave inverters

-

Differences and uses of single-phase inverters

Differences and uses of single-phase inverters

Commercial & Industrial Solar Storage Market Growth

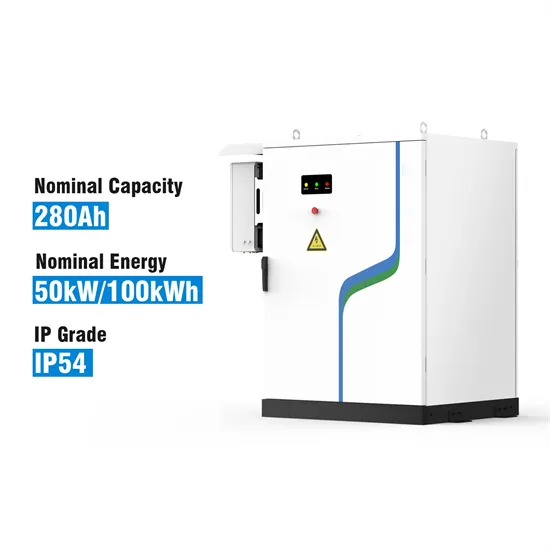

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.