Mechanical electricity storage

Flywheel energy storage systems (FESS) employ kinetic energy stored in a rotating mass with very low frictional losses. Electric energy input accelerates

Get Price

Permanent Magnet Motors in Energy Storage Flywheels

This verified the validity and applicability of the design and provided a reference and theoretical basis for improving the control quality of

Get Price

Flywheel Energy Storage: The Key To Sustainable

Flywheel energy storage is a promising technology that can provide fast response times to changes in power demand, with longer lifespan and higher efficiency

Get Price

Technology: Flywheel Energy Storage

There are five large (>500 kW), commercially operating systems: Two 20 MW-systems by Beacon Power are operated for frequency regulation in the USA. In Germany, a 600 kW storage

Get Price

Flywheel Energy Storage

Flywheel energy storage uses electric motors to drive the flywheel to rotate at a high speed so that the electrical power is transformed into mechanical power and stored, and when

Get Price

Permanent Magnet Motors in Energy Storage Flywheels

This verified the validity and applicability of the design and provided a reference and theoretical basis for improving the control quality of driving motor system used by new

Get Price

Flywheel energy storage systems: A critical review on

The principle of rotating mass causes energy to store in a flywheel by converting electrical energy into mechanical energy in the form of rotational kinetic energy. 39 The energy

Get Price

Flywheel Energy Storage

Flywheel energy storage technology uses reversible bidirectional motors (electric motor/generator) to facilitate the conversion between electrical energy and the mechanical

Get Price

Flywheel Energy Storage

Flywheel energy storage technology uses reversible bidirectional motors (electric motor/generator) to facilitate the conversion between electrical energy and the

Get Price

Overview of Flywheel Systems for Renewable Energy

Energy can be stored through various forms, such as ultra-capacitors, electrochemical batteries, kinetic flywheels, hydro-electric power or compressed air. Their comparison in terms of specific

Get Price

Flywheel energy storage systems: A critical review on

The principle of rotating mass causes energy to store in a flywheel by converting electrical energy into mechanical energy in the form of rotational

Get Price

10 Main Types of Energy Storage Methods in 2025

Types of Energy Storage Methods - Renewable energy sources aren''t always available, and grid-based energy storage directly tackles this issue.

Get Price

Flywheel Energy Storage System Basics

Today, flywheel energy storage systems are used for ride-through energy for a variety of demanding applications surpassing chemical batteries.

Get Price

A comprehensive review of Flywheel Energy Storage System

Flywheel (FW) saves the kinetic energy in a high-speed rotational disk connected to the shaft of an electric machine and regenerates the stored energy in the network when it is

Get Price

Flywheel

Flywheel A flywheel is a mechanical device used to store rotational energy in various applications. It consists of a heavy disc or wheel that rotates at high

Get Price

What are the types of flywheel energy storage methods?

Flywheel systems can broadly be classified into various types based on their components and operational principles. Mechanical flywheels,

Get Price

A Review of Flywheel Energy Storage System Technologies

This article comprehensively reviews the key components of FESSs, including flywheel rotors, motor types, bearing support technologies, and power electronic converter

Get Price

The Status and Future of Flywheel Energy Storage

Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electrical power system into one that is fully sustainable yet low

Get Price

What are the types of flywheel energy storage methods?

Flywheel systems can broadly be classified into various types based on their components and operational principles. Mechanical flywheels, magnetic bearing flywheels,

Get Price

FLYWHEEL ENERGY STORAGE SYSTEM AND IT''S

early examples of flywheel are potter''s wheel and spinning wheel. The basic steps in flywheel energy storage system (FESS) are to convert the available energy into electrical energy by

Get Price

DOE ESHB Chapter 7 Flywheels

For thousands of years, some form of flywheel technology has been used to smooth the flow of energy in rotating machinery from small, hand-held devices to the largest engines [1].

Get Price

FLYWHEEL ENERGY STORAGE SYSTEM AND IT''S

Abstract: Flywheel has been in use since long time for storing energy and other applications. The basic steps in flywheel energy storage system (FESS) are to convert the available energy into

Get Price

What is Flywheel Energy Storage? | Linquip

A flywheel energy storage system employed by NASA (Reference: wikipedia ) How Flywheel Energy Storage Systems Work? Flywheel

Get Price

Flywheel Energy Storage System: What Is It and How

A flywheel energy storage system is a mechanical device used to store energy through rotational motion. When excess electricity is available, it is used to

Get Price

Flywheel energy storage

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher

Get Price

A New Multi-Axial Flux Pm Motor–Generator System

This study presents a flywheel energy storage system utilizing a new multi-axial flux permanent magnet (MAFPM) motor–generator for coil

Get Price

Flywheels | Climate Technology Centre & Network | Tue, 11/08/2016

Components of a flywheel energy storage system A flywheel has several critical components. a) Rotor – a spinning mass that stores energy in the form of momentum (EPRI, 2002) The rotor,

Get Price

Introduction to motors and controllers of flywheel energy storage

The paper covers the principle and characteristics of permanent magnet brushless DC motors, permanent magnet synchronous motors, induction motors and switched reluctance motors,

Get Price

Flywheel energy storage

OverviewMain componentsPhysical characteristicsApplicationsComparison to electric batteriesSee alsoFurther readingExternal links

A typical system consists of a flywheel supported by rolling-element bearing connected to a motor–generator. The flywheel and sometimes motor–generator may be enclosed in a vacuum chamber to reduce friction and energy loss. First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors

Get Price

More related information

-

Battery types used in energy storage cabins

Battery types used in energy storage cabins

-

Battery types used in Huawei energy storage stations

Battery types used in Huawei energy storage stations

-

What wind power can be used for flywheel energy storage

What wind power can be used for flywheel energy storage

-

Superconducting energy storage flywheel

Superconducting energy storage flywheel

-

Flywheel energy storage equipment construction

Flywheel energy storage equipment construction

-

High-efficiency battery energy storage flywheel system

High-efficiency battery energy storage flywheel system

-

Migration flywheel energy storage project

Migration flywheel energy storage project

-

How much does flywheel energy storage wind power cost

How much does flywheel energy storage wind power cost

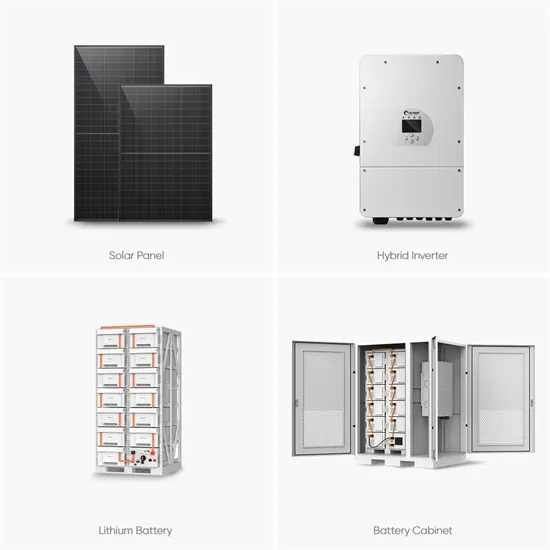

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.