Flywheel Energy Storage for Grid and Industrial

Flywheel Energy Storage Nova Spin included in TIME''s Best Inventions of 2024 List We''re thrilled to be one of the few selected in the Green Energy category

Get Price

The Whole Process of Flywheel Energy Storage: From Basics to

What Is Flywheel Energy Storage and Why Should You Care? Imagine a giant, supercharged spinning top that stores electricity like a battery— that''s flywheel energy storage

Get Price

Flywheel Energy Storage

Flywheel energy storage, an innovative mechanical energy storage method, will hold a significant position in the future energy storage field.

Get Price

Flywheel Energy Storage: The Key To Sustainable

Flywheel energy storage is a promising technology that can provide fast response times to changes in power demand, with longer lifespan and higher efficiency

Get Price

Flywheel Energy Storage System: What Is It and How

In a flywheel energy storage system, electrical energy is used to spin a flywheel at incredibly high speeds. The flywheel, made of durable materials like

Get Price

Beacon Power

Beacon flywheel storage increases the amount of wind and solar power that can be integrated and utilized, thereby reducing system fuel consumption.

Get Price

Flywheel Systems for Utility Scale Energy Storage

Flywheel Systems for Utility Scale Energy Storage is the final report for the Flywheel Energy Storage System project (contract number EPC-15-016) conducted by Amber Kinetics, Inc.

Get Price

Flywheel energy storage

OverviewMain componentsPhysical characteristicsApplicationsComparison to electric batteriesSee alsoFurther readingExternal links

Flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational energy. When energy is extracted from the system, the flywheel''s rotational speed is reduced as a consequence of the principle of conservation of energy; adding energy to the system correspondingly results in an increase in the speed of th

Get Price

$200 Million For Renewables-Friendly Flywheel Energy Storage

1 day ago· The Flywheel Of The Past Lives Again Flywheels have largely fallen off the energy storage news radar in recent years, their latter-day mechanical underpinnings eclipsed by the

Get Price

Why NASA''s Mechanical Battery Could Be the Future

NASA''s Glenn Research Center developed a new flywheel-based mechanical battery system that redefined energy storage and spacecraft

Get Price

RotorVault Flywheel Systems | Grid-Scale Energy Storage

RotorVault flywheel systems provide reliable and sustainable energy storage solutions for residential, commercial and grid-scale applications.

Get Price

Exploring Flywheel Energy Storage Systems and

Overall, the operating principles of flywheel technology underscore its potential as a robust energy solution. By mastering kinetic energy storage, efficient energy

Get Price

What is a Flywheel Storage System? High-Speed Energy Backup

Conclusion Flywheel storage systems represent a high-speed, efficient, and environmentally friendly energy storage solution. Their unique characteristics make them well

Get Price

Flywheel Energy Storage: A Comprehensive Guide

Discover the benefits and applications of flywheel energy storage in modern energy systems, including its role in grid stabilization and renewable energy integration.

Get Price

Flywheel Energy Storage: A High-Efficiency Solution

Flywheel energy storage is an exciting solution for efficient and sustainable energy management. This innovative technology offers high

Get Price

Energy Storage Flywheel Rotors—Mechanical Design

Energy storage flywheel systems are mechanical devices that typically utilize an electrical machine (motor/generator unit) to convert electrical energy in

Get Price

Technology: Flywheel Energy Storage

Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000

Get Price

A review of flywheel energy storage systems: state of the art and

There is noticeable progress in FESS, especially in utility, large-scale deployment for the electrical grid, and renewable energy applications. This paper gives a review of the

Get Price

Flywheel Energy Storage System: What Is It and How Does It

In a flywheel energy storage system, electrical energy is used to spin a flywheel at incredibly high speeds. The flywheel, made of durable materials like composite carbon fiber, stores energy in

Get Price

A Review of Flywheel Energy Storage System Technologies

Using energy storage technology can improve the stability and quality of the power grid. One such technology is flywheel energy storage systems (FESSs).

Get Price

A review of flywheel energy storage systems: state of the art

The ex-isting energy storage systems use various technologies, including hydro-electricity, batteries, supercapacitors, thermal storage, energy storage flywheels,[2] and

Get Price

Flywheel Energy Storage

Advances in power electronics, magnetic bearings, and flywheel materials coupled with innovative integration of components have resulted in direct current (DC) flywheel energy storage

Get Price

How do flywheels store energy?

When there is a sudden surge in renewable energy production (e.g., a gust of wind or a burst of sunshine), the excess energy is used to spin up a flywheel, storing it as rotational

Get Price

Flywheel Energy Storage: The Key To Sustainable Energy Solutions

Flywheel energy storage is a promising technology that can provide fast response times to changes in power demand, with longer lifespan and higher efficiency compared to other

Get Price

Flywheel Energy Storage

Energy storage solutions are essential for integrating renewable energy sources like wind and solar by mitigating intermittency, enhancing grid reliability, and optimizing energy

Get Price

How Does a Flywheel Energy Storage System Work?

The energy storage capacity of a flywheel is determined by two main factors: the mass of the rotor and the speed at which it spins. A heavier rotor or a faster spinning rotor can

Get Price

Flywheel energy storage

Flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational energy. When energy is extracted from the

Get Price

6 FAQs about [Energy storage flywheel appears]

How does Flywheel energy storage work?

Flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational energy.

What is the difference between a flywheel and a battery storage system?

Flywheel Systems are more suited for applications that require rapid energy bursts, such as power grid stabilization, frequency regulation, and backup power for critical infrastructure. Battery Storage is typically a better choice for long-term energy storage, such as for renewable energy systems (solar or wind) or home energy storage.

How does a flywheel work?

Here’s a breakdown of the process: Energy Absorption: When there’s surplus electricity, such as when the grid is overproducing energy, the system uses that excess power to accelerate the flywheel. This energy is stored as kinetic energy, much like how the figure skater speeds up their spin by pulling in their arms.

Are flywheel energy storage systems sustainable?

With proper maintenance, flywheels can operate for over two decades, making them a more sustainable option than batteries. However, flywheel energy storage systems also have some disadvantages. One of the main challenges of flywheel systems is friction loss, which can cause energy loss and reduce efficiency.

What is flywheel/kinetic energy storage system (fess)?

and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently. There is noticeable progress in FESS, especially in utility, large-scale deployment for the electrical grid, and renewable energy applications. This paper gives a review of the recent

What are the disadvantages of Flywheel energy storage systems?

However, flywheel energy storage systems also have some disadvantages. One of the main challenges of flywheel systems is friction loss, which can cause energy loss and reduce efficiency. This means that flywheels require regular maintenance to minimize energy loss due to friction.

More related information

-

Calculation of power consumption of flywheel energy storage equipment

Calculation of power consumption of flywheel energy storage equipment

-

Flywheel energy storage new energy industry

Flywheel energy storage new energy industry

-

What is flywheel energy storage wind power

What is flywheel energy storage wind power

-

The role of flywheel energy storage motor

The role of flywheel energy storage motor

-

Flywheel energy storage compartment

Flywheel energy storage compartment

-

Cost per watt of flywheel energy storage

Cost per watt of flywheel energy storage

-

Iran superconducting flywheel energy storage system

Iran superconducting flywheel energy storage system

-

Vanuatu Energy Storage Flywheel

Vanuatu Energy Storage Flywheel

Commercial & Industrial Solar Storage Market Growth

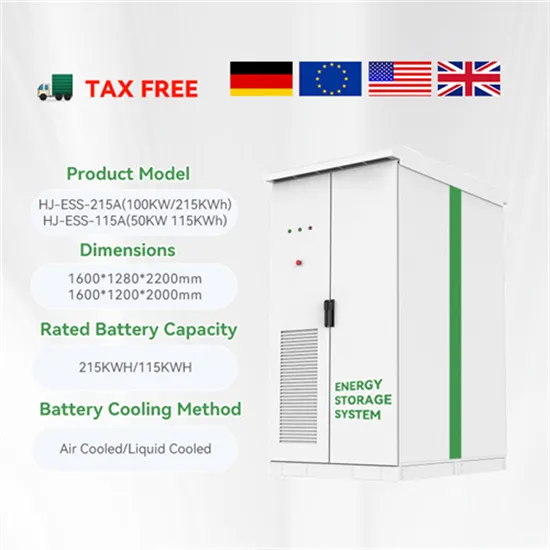

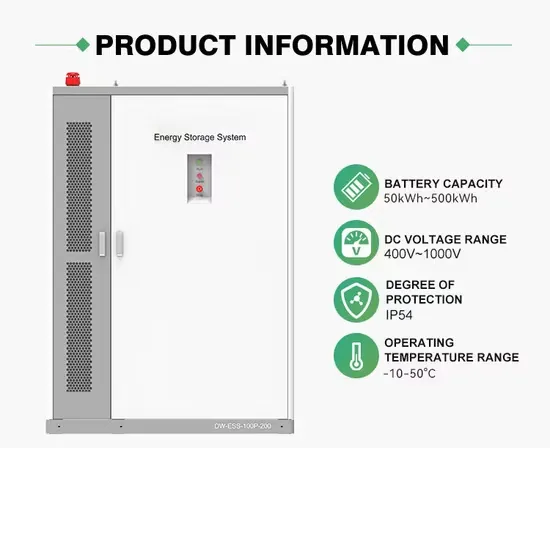

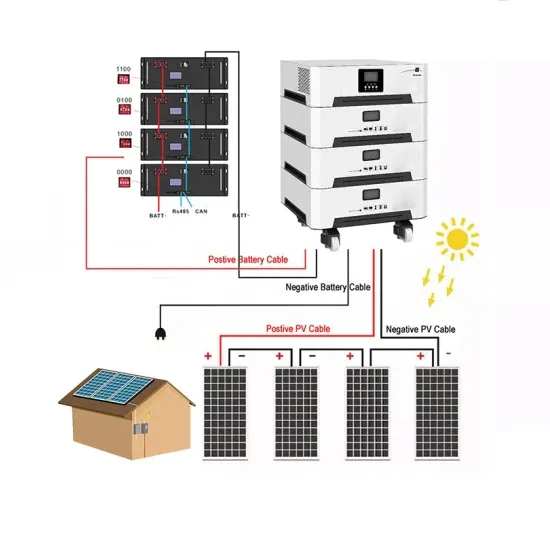

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.