Crystalline Silicon Solar Cell

Crystalline solar cells have long been used for the development of SPV systems, and known to exhibit the excellent longevity. The first crystalline silicon based solar cell was developed

Get Price

Multicrystalline Silicon Cell

The most common solar cells used in commercially available solar panels are crystalline silicon PV cells. Typically, solar cells are manufactured from single-crystalline silicon or

Get Price

Crystalline Silicon Photovoltaics Research

DOE supports crystalline silicon photovoltaic (PV) research and development efforts that lead to market-ready technologies.

Get Price

Crystalline Silicon Module

Crystalline silicon (c-Si) modules dominate the PV market with a 95% share [73]. The cells are available in multicrystalline (multi-Si) and mono-crystalline (mono-Si) variants, with mono-Si as

Get Price

Utility solar photovoltaic capacity is dominated by crystalline silicon

Most of the growing number of installations of utility-scale solar photovoltaic (PV) operating capacity across the United States have been systems that make use of crystalline

Get Price

Understanding Crystalline Silicon PV Technology

Learn everything you need to know about Crystalline Silicon PV technology, from its basic principles to its applications in solar panels.

Get Price

Crystalline silicon

Crystalline silicon is the dominant semiconducting material used in photovoltaic technology for the production of solar cells. These cells are assembled into solar panels as part of a photovoltaic

Get Price

Crystalline and Thin Film Solar Panels | The Difference

Solar panel energy and photovoltaic cells provide a solution for societies to generate clean energy and ensure future energy security. While the solar industry has been around for decades, two

Get Price

High-Efficiency Crystalline Photovoltaics | Photovoltaic Research | NREL

NREL is working to increase cell efficiency and reduce manufacturing costs for the highest-efficiency photovoltaic (PV) devices involving single-crystal silicon and III-Vs.

Get Price

What Is a Monocrystalline Solar Panel? Definition,

A monocrystalline (mono) solar panel is a type of solar panel that uses solar cells made from a single silicon crystal. The use of a single silicon

Get Price

Sustainable Strategies for Crystalline Solar Cell Recycling: A

The classification of PV recycling companies based on various components, including solar panels, PV glass, aluminum frames, silicon solar cells, junction boxes, plastic,

Get Price

Why Silicon is the Most Widely Used Material in Solar

Discover why silicon is used in solar panels as the key material for harvesting clean energy efficiently. Explore its vital role in solar technology.

Get Price

Advancements in Photovoltaic Cell Materials: Silicon, Organic,

We scrutinize the unique characteristics, advantages, and limitations of each material class, emphasizing their contributions to efficiency, stability, and commercial viability. Silicon-based

Get Price

Advancements in Photovoltaic Cell Materials: Silicon,

We scrutinize the unique characteristics, advantages, and limitations of each material class, emphasizing their contributions to efficiency, stability, and

Get Price

Crystalline Silicon Photovoltaics

Crystalline silicon solar cells are connected together and then laminated under toughened or heat strengthened, high transmittance glass to produce reliable,

Get Price

How Monocrystalline Solar Cells Work

Monocrystalline vs Polycrystalline Solar Panels Crystalline silicon solar cells derive their name from the way they are made. The difference

Get Price

Crystalline Silicon Photovoltaics

Crystalline silicon solar cells are connected together and then laminated under toughened or heat strengthened, high transmittance glass to produce reliable, weather resistant photovoltaic

Get Price

What is the Difference between Thin-Film and

Thin film as well as crystalline silicon panels vary in efficiency, durability, size, and cost. Thin-film panels are less expensive and more

Get Price

Crystalline Silicon Photovoltaic Cells, Whether or Not Assembled

The merchandise covered by the Orders are crystalline silicon photovoltaic cells, and modules, laminates, and panels, consisting of crystalline silicon photovoltaic cells,

Get Price

Crystalline silicon

SummaryOverviewPropertiesCell technologiesMono-siliconPolycrystalline siliconNot classified as Crystalline siliconTransformation of amorphous into crystalline silicon

Crystalline silicon or (c-Si) is the crystalline forms of silicon, either polycrystalline silicon (poly-Si, consisting of small crystals), or monocrystalline silicon (mono-Si, a continuous crystal). Crystalline silicon is the dominant semiconducting material used in photovoltaic technology for the production of solar cells. These cells are assembled into solar panels as part of a photovoltaic system to generate solar power

Get Price

Characteristics of Crystalline Silicon PV Modules

Single crystalline silicon (also known as monocrystalline silicon) and multi-crystalline silicon (also known as polycrystalline silicon) are two

Get Price

(PDF) Crystalline Silicon Solar Cells: State-of-the-Art and Future

Crystalline silicon solar cells have dominated the photovoltaic market since the very beginning in the 1950s. Silicon is nontoxic and abundantly available in the earth''s crust, and

Get Price

Properties of polycrystalline silicon cell

In integrated capacitors, polycrystalline silicon forms the conductive plates, while silicon oxide serves as the dielectric. Compared to

Get Price

Thin-film solar cell

Thin-film solar cells are a type of solar cell made by depositing one or more thin layers (thin films or TFs) of photovoltaic material onto a substrate, such as

Get Price

Understanding Crystalline Silicon PV Technology

Learn everything you need to know about Crystalline Silicon PV technology, from its basic principles to its applications in solar panels.

Get Price

High-Efficiency Crystalline Photovoltaics | Photovoltaic Research

NREL is working to increase cell efficiency and reduce manufacturing costs for the highest-efficiency photovoltaic (PV) devices involving single-crystal silicon and III-Vs.

Get Price

Characteristics of Crystalline Silicon PV Modules

Single crystalline silicon (also known as monocrystalline silicon) and multi-crystalline silicon (also known as polycrystalline silicon) are two forms of crystalline silicon (c

Get Price

Solar cell

Individual solar cell devices are often the electrical building blocks of photovoltaic modules, known colloquially as "solar panels". Almost all commercial PV cells

Get Price

Why Silicon Remains the Top Choice for Solar Panels

This abundance is a key driver behind the dramatic reduction in solar panel costs over the past decade. Silicon-based panels are now more

Get Price

Status and perspectives of crystalline silicon photovoltaics in

In this Review, we survey the key changes related to materials and industrial processing of silicon PV components.

Get Price

More related information

-

Austrian crystalline silicon photovoltaic solar panels

Austrian crystalline silicon photovoltaic solar panels

-

Middle East crystalline silicon photovoltaic modules solar panels

Middle East crystalline silicon photovoltaic modules solar panels

-

What are the monocrystalline silicon panels in photovoltaic plants

What are the monocrystalline silicon panels in photovoltaic plants

-

Photovoltaic monocrystalline silicon solar panels

Photovoltaic monocrystalline silicon solar panels

-

What are Montenegro monocrystalline silicon photovoltaic panels

What are Montenegro monocrystalline silicon photovoltaic panels

-

Polycrystalline silicon photovoltaic panels for power generation

Polycrystalline silicon photovoltaic panels for power generation

-

Solar cells and photovoltaic panels matching

Solar cells and photovoltaic panels matching

-

Photovoltaic crystalline silicon panel manufacturer

Photovoltaic crystalline silicon panel manufacturer

Commercial & Industrial Solar Storage Market Growth

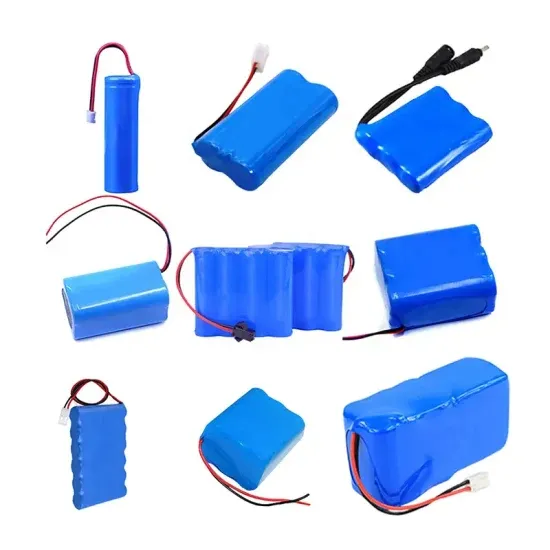

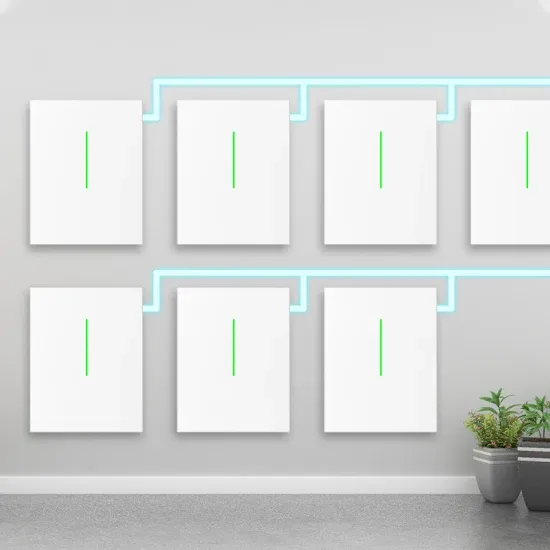

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.