Technical notes on output rating, operating

3. Power loss and efficiency as a function of load As an example let us look at the Phoenix Inverter 24/3000 or MultiPlus 24/3000/70 (both products have the same inverter). These

Get Price

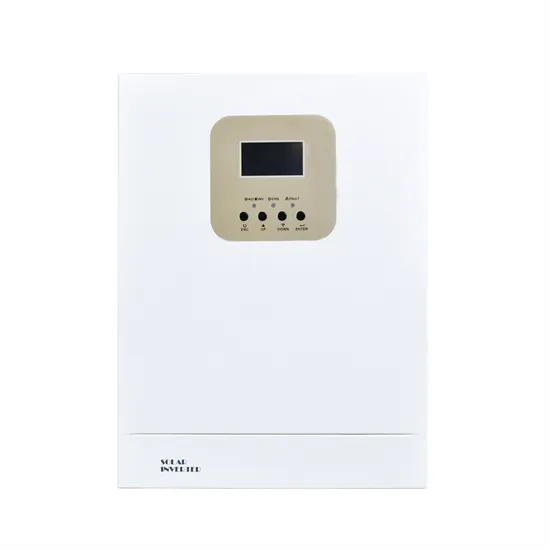

Inverter Specifications and Data Sheet

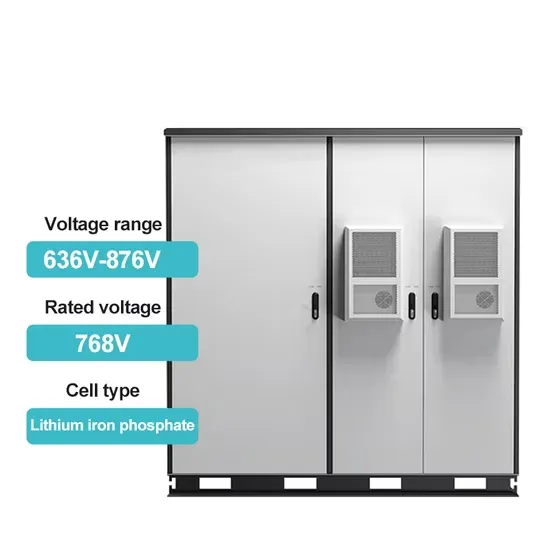

Both the maximum voltage value and operating voltage range of an inverter are two main parameters that should be taken into account when stringing the inverter and PV array.

Get Price

Understanding Inverter Voltage: Definition, Functions, Type, and

Medium voltage inverters themselves have input voltage power ranging from 100V to 600V. While the output voltage is usually 208V, 400V, or 480V.

Get Price

When choosing an inverter, what voltage ratings should you pay

The operating voltage range is the range of voltages within which an inverter can continuously function without damage. Operating voltage range 5 ensures your inverter runs smoothly

Get Price

What Is Nominal Operating Voltage In Solar Inverter

Input specifications of an inverter are crucial for understanding the characteristics of the AC power it produces for consumption. The nominal operating voltage (NOMINAL) is

Get Price

6.4. Inverters: principle of operation and parameters

6.4. Inverters: principle of operation and parameters Now, let us zoom in and take a closer look at the one of the key components of power conditioning chain -

Get Price

Inverter Specifications and Data Sheet

The article provides an overview of inverter functions, key specifications, and common features found in inverter systems, along with an example of power calculations and inverter

Get Price

When choosing an inverter, what voltage ratings

The operating voltage range is the range of voltages within which an inverter can continuously function without damage. Operating voltage range 5 ensures

Get Price

Inverter Voltage Calculator, Formula, Inverter Voltage Calculation

Inverter voltage, V (V) = V DC (V) * dm. V (V) = inverter voltage in volts, V. V DC (V) = DC voltage in volts, V. dm = modulation index. Given: V DC (V) = 400V, dm = 0.8. Inverter voltage, V (V) =

Get Price

How to Read Solar Inverter Specifications

The start-up voltage is the minimum voltage potential needed for the inverter to start functioning. For effective performance, it is recommended to confirm if the solar panel''s

Get Price

Inverter Power Factor Modes: How do they afect voltage rise

Inverter Power Factor Modes: How do they afect voltage rise calculations? As Australia continues to see the trend to increase system capacity to medium or large scale Grid-connected PV

Get Price

Motor Tip Sheet #14: When Should Inverter-Duty Motors Be

Voltage spikes have been reported with peak values as high as 2150 volts in a 460 V system operating at 10% over voltage. High voltage spikes can lead to insulation breakdown, resulting

Get Price

Understanding inverter startup voltage.

I would say 90v for EACH MPPT input, separately. So if your inverter has only one MPPT input, that''s 90v. If your inverter has two or more MPPT inputs, that''s 90v for each one.

Get Price

Nominal and maximum power of an inverter: Are they

This is the first value that an inverter displays; for example, an indicative form could be 500 W / 1000 W maximum. In this case, the nominal

Get Price

How to Choose the Operating Mode of Solar Inverter?

The solar inverter works in battery mode, and the load capacity is lower than 10% of the rated power of the inverter, the inverter will start and stop regularly to achieve energy

Get Price

Dielectric Testing for Solar Inverters: A Comprehensive Guide for

The test involves applying an AC voltage higher than the inverter''s normal operating voltage to check for insulation integrity. How It Works: A high AC voltage, typically 2-3 times

Get Price

Understanding inverter voltage

Choosing the optimal inverter voltage depends on various factors, including the inverter''s design, the power requirements of connected devices, and the available power source.

Get Price

Understanding Inverter Voltage: Definition, Functions,

Medium voltage inverters themselves have input voltage power ranging from 100V to 600V. While the output voltage is usually 208V, 400V, or

Get Price

What Is Operating Voltage? Definition and Examples

An example of this is when a 230V circuit has an input voltage of 230V and other internal parts that operate at say 110V or 80V. The operating voltage is different across

Get Price

Introduction to inverters: structure, operating

Discover the basics of inverters - their structure, operating principles, and functions. Explore Junchipower''s expertise in this informative

Get Price

An Overview of Issues Related to IEEE Std 1547-2018

Both Category A and Category B DERs must be capable of operating in three voltage regulation modes: (1) constant power factor mode, (2) constant reactive power mode, and (3) voltage

Get Price

Mppt voltage range vs max DC input voltage

what''s the difference between max MPPT voltage range and max DC input voltage? My inverter max dc input is 600V and the max range goes up to 550V. I''m wanting to

Get Price

Inverter minimum input voltages and string sizes

I am wondering about the minimum input voltage needed to turn on an inverter. For example the Sunny Boy 6000TL-US-22 has a minimum voltage input of

Get Price

Inverter Battery Voltage: How Many Volts Are Needed For

An inverter battery typically operates at 12V, 24V, or 48V. These voltages represent the nominal direct current (DC) needed for the inverter''s function.

Get Price

Interpreting inverter datasheet and main parameters | AE 868

Both the maximum voltage value and operating voltage range of an inverter are two main parameters that should be taken into account when stringing the inverter and PV array.

Get Price

How to Read Solar Inverter Specifications

The start-up voltage is the minimum voltage potential needed for the inverter to start functioning. For effective performance, it is recommended

Get Price

Technical White Paper SolarEdge Single Phase Inverter

circuit voltage (equal to the sum of all power optimizer ouput voltages) only increases to the normal operating voltage when connected to a properly operating inverter. The system

Get Price

What Is Nominal Operating Voltage In Solar Inverter

Input specifications of an inverter are crucial for understanding the characteristics of the AC power it produces for consumption. The nominal

Get Price

6 FAQs about [Inverter normal operating voltage]

What is the input voltage of an inverter?

Understanding the inverter voltage is crucial for selecting the right equipment for your power system. Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function optimally. What is the rated input voltage of an inverter?

What are inverter specifications?

Specifications provide the values of operating parameters for a given inverter. Common specifications are discussed below. Some or all of the specifications usually appear on the inverter data sheet. Maximum AC output power This is the maximum power the inverter can supply to a load on a steady basis at a specified output voltage.

How much power does an inverter need?

It’s important to note what this means: In order for an inverter to put out the rated amount of power, it will need to have a power input that exceeds the output. For example, an inverter with a rated output power of 5,000 W and a peak efficiency of 95% requires an input power of 5,263 W to operate at full power.

What voltage is a 12V inverter?

Inverters come in various configurations, each designed for specific power systems. Common rated input voltages include 12V, 24V, and 48V. The choice depends on the application, the size of the power system, and the available power source. A 12V inverter is commonly used for smaller applications, such as in vehicles or small off-grid setups.

What is an example of a power inverter?

Common examples are refrigerators, air-conditioning units, and pumps. AC output voltage This value indicates to which utility voltages the inverter can connect. For inverters designed for residential use, the output voltage is 120 V or 240 V at 60 Hz for North America. It is 230 V at 50 Hz for many other countries.

What are inverter voltage ratings?

Inverter voltage ratings are critical to ensure compatibility with your solar system and battery setup. Pay attention to these numbers. When selecting an inverter, understanding voltage ratings ensures proper system compatibility, efficiency, and longevity. Key ratings to focus on include rated voltage, maximum input voltage, and others.

More related information

-

220v inverter operating voltage range

220v inverter operating voltage range

-

Is the inverter voltage 217v normal

Is the inverter voltage 217v normal

-

Is it normal for the inverter to output 246V AC voltage

Is it normal for the inverter to output 246V AC voltage

-

Centralized inverter voltage

Centralized inverter voltage

-

Inverter has high voltage

Inverter has high voltage

-

What is the maximum input voltage of a 48v inverter

What is the maximum input voltage of a 48v inverter

-

Wide voltage inverter with high power

Wide voltage inverter with high power

-

Single-phase inverter voltage

Single-phase inverter voltage

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.