Battery and Energy Storage

We design and manufacturer each battery enclosure to meet the precise needs and requirements of YOUR project. Every Battery Enclosure is manufactured to spec, meeting size and weight

Get Price

OEM |BESS Container|Billion Electric

Localized assembly of battery cabinets and containers in the production line, completing calibration testing and system integration. Design and planning, construction and adjustment,

Get Price

BATTERY ENERGY STORAGE SYSTEMS

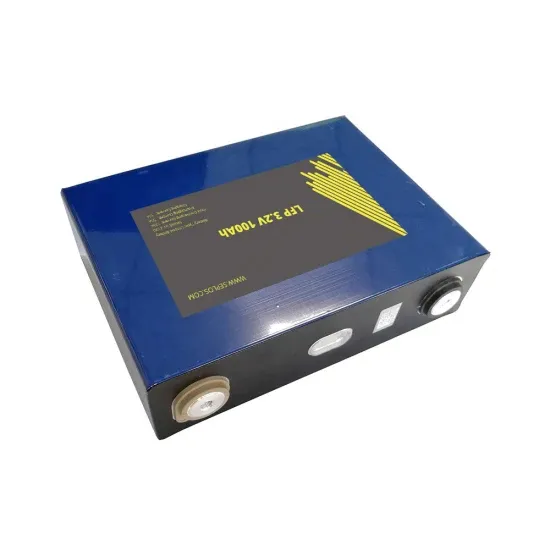

The rst block is the battery cell. When connecting several battery cells in series or/and in parallel, you will create a battery pack (or bat- tery module). When connecting several battery packs in

Get Price

Battery Assembly Plant

By following a structured procurement process and considering key factors such as equipment specifications, vendor reputation, and support services, businesses can ensure that

Get Price

Complete Guide for Battery Enclosure

Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or cabinet is always a

Get Price

Battery Enclosures

Our first battery enclosure was produced in Europe in 2011 for a hybrid electric vehicle. Magna provides a comprehensive range of battery enclosure production and engineering solutions,

Get Price

Innovating battery assembly

Innovating battery assembly Solutions that bring productivity, quality, and sustainability in e-mobility and battery manufacturing to a new level

Get Price

Clean/Dry Rooms for Lithium Ion Battery Manufacturing

In a lithium-ion battery, you''ll find pressurized containers that house a coil of metal and a flammable, lithium-containing liquid. The manufacturing process creates tiny pieces of metal

Get Price

Complete Guide for Battery Enclosure

Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or

Get Price

Battery Plant Design | Architecture and Engineering Firm

Our interdisciplinary team combines a well-balanced blend of Battery expertise and cutting-edge project execution to provide our clients with greater quality, transparency, and efficiency.

Get Price

RACK & CABINET

VRLA battery assembly cabinets are very durable, and easy to install. Engineered for use with most type of battery terminal models, these cabinets can fit a wide

Get Price

Uninterruptible Power Supply (UPS) Backup Battery

Battery Cabinets Arimon designs and manufactures custom uninterruptible power supply (UPS) backup battery cabinets, battery racks and accessories for the

Get Price

U.S. Battery Gigafactories [2025 List] | EV Supply

This is a list of all lithium battery gigafactories in the U.S. and the major ones worldwide. A large gigafactory can consume 2.4 GWh of electricity and 1

Get Price

U.S. Battery Gigafactories [2025 List] | EV Supply Chain

This is a list of all lithium battery gigafactories in the U.S. and the major ones worldwide. A large gigafactory can consume 2.4 GWh of electricity and 1 million gallons of water daily.

Get Price

OEM |BESS Container|Billion Electric

Localized assembly of battery cabinets and containers in the production line, completing calibration testing and system integration. Design and planning,

Get Price

Customized Lithium-Ion Battery Storage Cabinets | Wesgar

Rely on Wesgar to produce first-class battery enclosures and take care of your unique needs. Our quality custom lithium-ion battery storage cabinets are skillfully fabricated leveraging our 250+

Get Price

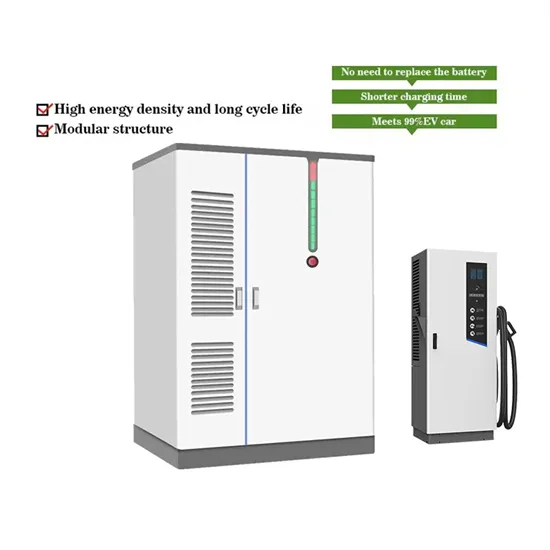

The Role of Battery Cabinet Systems in Modern Energy Storage

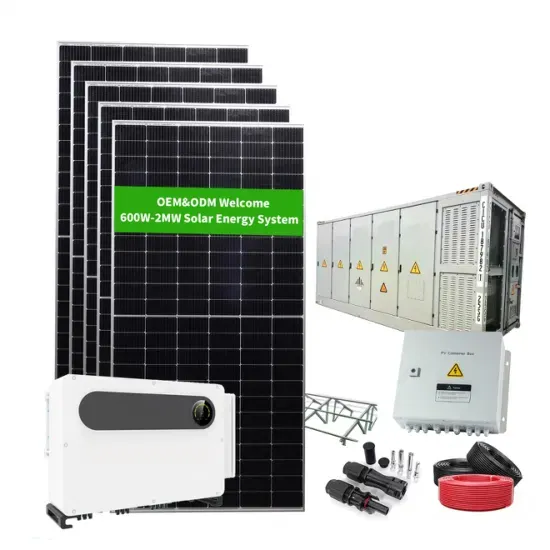

A battery cabinet system is an integrated assembly of batteries enclosed in a protective cabinet, designed for various applications, including peak shaving, backup power,

Get Price

Battery Energy Storage System (BESS)

Battery Energy Storage System (BESS) To the extent that this report is based on information supplied by other parties, Hatch accepts no liability for any loss or damage suffered, whether

Get Price

NETSURE 7100 SERIES

Improving reliability Where constant migration and change is the norm The NetSure 7100 Series of -48V DC power systems delivers outstanding reliability within a modular, scalable stand

Get Price

Battery Plant Design | Architecture and Engineering Firm

Our interdisciplinary team combines a well-balanced blend of Battery expertise and cutting-edge project execution to provide our clients with greater quality,

Get Price

battery cabinet,battery storage cabinet,battery bank

EverExceed VRL A battery assembly cabinets are very durable, and easy to install. Engineered for use with most type of battery terminal models, these

Get Price

SSOE Group | Battery Manufacturing | Battery Plant Design

Our proficiency is born from hands-on experience at the vanguard of a leading electric vehicle manufacturer''s plant, encompassing the entirety of battery assembly pack processes.

Get Price

Enclosed Battery Cabinet 6 Slot with Bus Bar

This 6 Slot Battery Cabinet is designed for secure and easy battery storage. Here are the key features: ★ Enclosed Cabinet: The door swings open for easy

Get Price

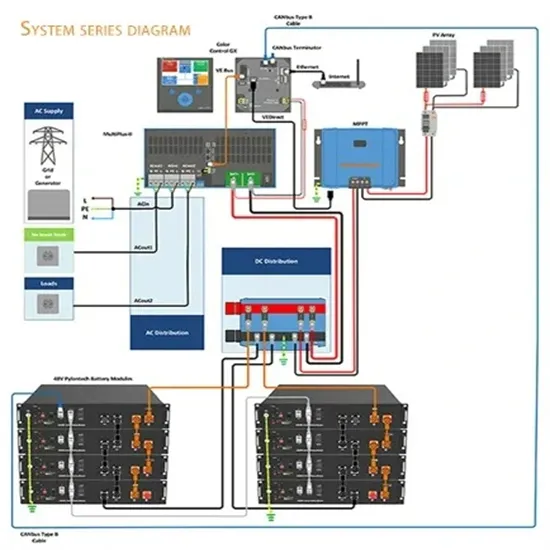

A Guide to Battery Energy Storage System

A battery energy storage system (BESS) contains several critical components. This guide will explain what each of those components does.

Get Price

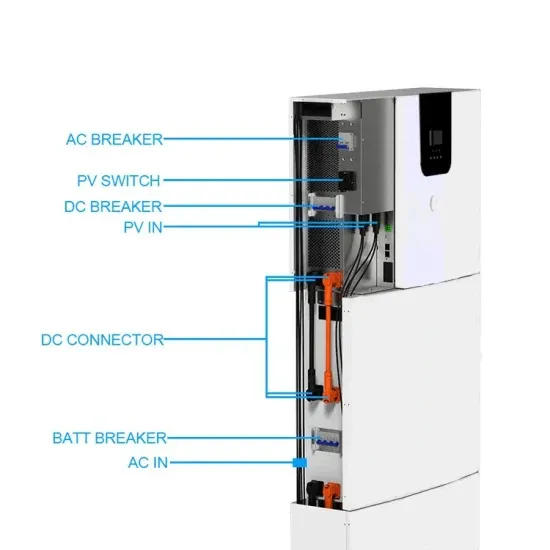

How to design an energy storage cabinet: integration and

This article will introduce in detail how to design an energy storage cabinet device, and focus on how to integrate key components such as PCS (power conversion system), EMS

Get Price

Battery Plant Design Do''s and Don''ts

An EV battery manufacturing plant is much different than a traditional automotive assembly plant, because of the high-speed production processes that take place within a

Get Price

Battery Cabinets and Enclosures Manufacture

We''re one of the industry leader in manufacturing of battery cabinets and enclosures that rank highest in quality, safety, maintenance and ease of use.

Get Price

6 FAQs about [Battery cabinet assembly plant]

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

What are the parts of a battery storage cabinet?

Let’s look at the most common parts: Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels. Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure.

When was the first battery enclosure made?

Our first battery enclosure was produced in Europe in 2011 for a hybrid electric vehicle. Magna provides a comprehensive range of battery enclosure production and engineering solutions, available in steel, aluminum, and innovative one-piece designs.

Where will EV batteries be made in 2026?

The reshoring and building of a domestic lithium battery supply chain is in full swing in the U.S., with a bevy of new EV battery manufacturing plants and factories coming online by 2026. #1 - Tesla Gigafactory Nevada will be the largest EV battery factory in the U.S. in 2025 with an expanded capacity of 100 GWh (up from 37 GWh).

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

How are battery plants different from other types of Advanced Manufacturing?

Battery plants are also different from other types of advanced manufacturing. For instance, clean rooms for semiconductor manufacturing are not dry rooms. They contain 30 times more humidity than the ultra-low requirements for battery plants.

More related information

-

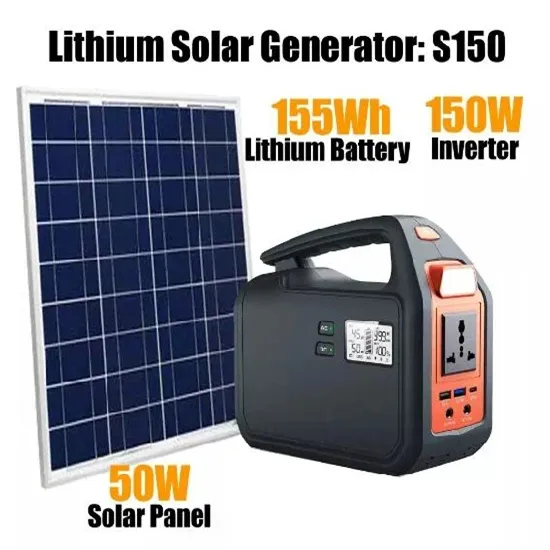

New Energy Battery Cabinet Assembly Plant

New Energy Battery Cabinet Assembly Plant

-

New Energy Battery Cabinet Assembly Site

New Energy Battery Cabinet Assembly Site

-

Heishan Energy Storage Lithium Battery Assembly Plant

Heishan Energy Storage Lithium Battery Assembly Plant

-

Egypt energy storage cabinet battery assembly

Egypt energy storage cabinet battery assembly

-

Energy storage cabinet battery production plant system

Energy storage cabinet battery production plant system

-

Cook Islands Energy Storage Cabinet Battery Assembly

Cook Islands Energy Storage Cabinet Battery Assembly

-

North Korea energy storage cabinet battery assembly

North Korea energy storage cabinet battery assembly

-

Energy Storage Battery Cabinet Assembly Cost Site

Energy Storage Battery Cabinet Assembly Cost Site

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.