What equipment are used to make solar panels?

To manufacture solar panels, various advanced materials and specialized instruments are deployed. 1. Silicon wafers, the core component,

Get Price

What equipment are used to make solar panels? | NenPower

To manufacture solar panels, various advanced materials and specialized instruments are deployed. 1. Silicon wafers, the core component, are essential as they convert

Get Price

Harnessing Solar Power: A Comprehensive Guide to Solar Panel

Solar panel making machines are specialized equipment used in the manufacturing process of solar panels, including machines for producing silicon ingots, wafers, cells, and

Get Price

Solar Production Equipment

In the solar sector, European companies originally played a key role in developing the production equipment needed for the mass production of solar wafers, cells, and modules.

Get Price

The Role of Machinery in PV Production | Eco Green Energy

The equipment behind PV module production is at the heart of the solar revolution. As technology continues to evolve, the role of automation, AI, and energy-efficient machines will only grow.

Get Price

The Equipment You Need For A Solar Panel System

The components of a solar panel system are pretty simple. But different product options and brands can sometimes make the equipment

Get Price

How Does Solar Power Produce Energy? A Simple Guide

How does solar power produce energy? Solar panels convert sunlight into electricity through photovoltaic cells made of silicon semiconductors.

Get Price

Essential Equipment and Materials in Solar Panel Production

The production of solar panels is a complex and multi-stage process that involves various types of equipment designed to enhance efficiency and ensure quality. At its core, solar panel

Get Price

Solar Cell Manufacturing Equipment: Key Devices in the

Each piece of equipment plays a crucial role in transforming raw materials into efficient, high-quality solar cells. This article provides an in-depth look at the key manufacturing equipment

Get Price

The Role of Machinery in PV Production | Eco Green

The equipment behind PV module production is at the heart of the solar revolution. As technology continues to evolve, the role of automation, AI, and

Get Price

Solar Photovoltaic Manufacturing Basics

While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems.

Get Price

8 Major Raw Materials Used for Making Solar Panels

From Aluminum Frames to Solar Cells, explore all the key raw material components that are used in making solar panels.

Get Price

Solar Panel Making Machines: A Guide to the Production Process

In this comprehensive guide, you will discover a fundamental overview of solar panel making machines and production processes essential for understanding solar panel

Get Price

What are the solar panel production equipment?

1. Solar panel production equipment comprises various machines and tools necessary for manufacturing solar photovoltaic cells, modules, and

Get Price

Executive summary – Solar PV Global Supply Chains

Global capacity for manufacturing wafers and cells, which are key solar PV elements, and for assembling them into solar panels (also known as modules),

Get Price

Solar Equipment And Installation

Solar Panel Installation Northern Virginia Solar Energy Equipment At Prospect Solar, we specialize in the design and installation of solar photovoltaic energy

Get Price

Solar Panel Laminator: A Guide to the Lamination

During production, solar panel laminators use heat and pressure to bond different layers of a solar panel together, creating a durable and

Get Price

Solar Panel Manufacturing Process: Step-by-Step Guide

The key components in solar PV manufacturing include silicon wafers, solar cells, PV modules, and solar panels. Silicon is the primary material used, which is processed into

Get Price

Solar Power System Equipment: Needs, Costs, Pros,

Key takeaways There are three main types of residential solar panel installations: grid-tied, hybrid, and off-grid. Grid-tied systems are the most common and the

Get Price

Solar Photovoltaic Manufacturing Basics

While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems. Those systems are comprised of PV

Get Price

Solar Cell Manufacturing Equipment: Key Devices in the Production

Each piece of equipment plays a crucial role in transforming raw materials into efficient, high-quality solar cells. This article provides an in-depth look at the key manufacturing equipment

Get Price

Where are solar panels made? [Top 9 countries, 2025]

Wondering where solar panels are manufactured? We run through the nine countries that dominate solar panel production, from Canada to Taiwan.

Get Price

Solar panel production equipment and machinery

In this instance we will use the 100MW Line, consisting of the following equipment and accessories: Main machinery: Solar simulator. Accessories: Laboratory accessories for

Get Price

Panel Laminators | Solar Module Manufacturing | Horad

Horad provides two types of quality solar panel laminators, double layer and three chamber laminators and double layer and double chamber laminators. The laminating machines adopt

Get Price

What are the solar panel production equipment? | NenPower

Solar panel production equipment comprises various machines and tools necessary for manufacturing solar photovoltaic cells, modules, and systems, including(1)

Get Price

The 3 Different Types of Solar Power Systems Explained

There are three basic types of solar power systems: grid-tie, off-grid, and backup power systems. Here''s a quick summary of the differences between them: Off

Get Price

6 FAQs about [What are the three major equipments for producing solar panels ]

What equipment do you need to make solar panels?

Main machinery: Solar simulator. Accessories: Laboratory accessories for quality control. Setting a production line of solar panels is a task that requires know-how and experience.

Where can I find the latest solar panels production & testing machines?

Discover the latest Solar panels’ production & testing machines from Ecoprogetti Srl by clicking here. Solar panel production equipment and machinery Nowadays the solar panels’ production equipment is divided into the following required machinery and accessories.

How does solar manufacturing work?

How Does Solar Work? Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems.

What are the different types of solar energy systems?

Photovoltaic (PV) System: This technology converts sunlight directly into electricity using solar panels made of semiconductor materials like silicon. Solar Thermal Systems: This technology uses sunlight to heat fluids, which can then be used for heating or electricity generation in concentrated solar power (CSP) plants. 1.

How are solar panels manufactured?

Nowadays the solar panels’ production equipment is divided into the following required machinery and accessories. The first run automated processes are the stringing and lamination, but also the analysis of quality as electroluminescence tests. These and other procedures are indispensable for the correct manufacture of the module in each component.

What are the key PV module manufacturing equipment?

Let’s break down the key PV module manufacturing equipment and how they contribute to the overall process: The heart of solar cell production lies in silicon wafers. These wafers are the building blocks of solar cells. Wafering machines use diamond wire saws to slice silicon ingots into thin sheets, often less than 200 microns thick.

More related information

-

What are the manufacturers of solar panels for communication base stations

What are the manufacturers of solar panels for communication base stations

-

What are the differences between solar panels of different wattages

What are the differences between solar panels of different wattages

-

What is the best voltage for solar panels

What is the best voltage for solar panels

-

What are the brands of container solar panels

What are the brands of container solar panels

-

What are solar panels made of

What are solar panels made of

-

What are the equipments of wind solar and energy storage power stations

What are the equipments of wind solar and energy storage power stations

-

What is the unit cost of solar panels

What is the unit cost of solar panels

-

What types of solar panels are there in photovoltaic modules

What types of solar panels are there in photovoltaic modules

Commercial & Industrial Solar Storage Market Growth

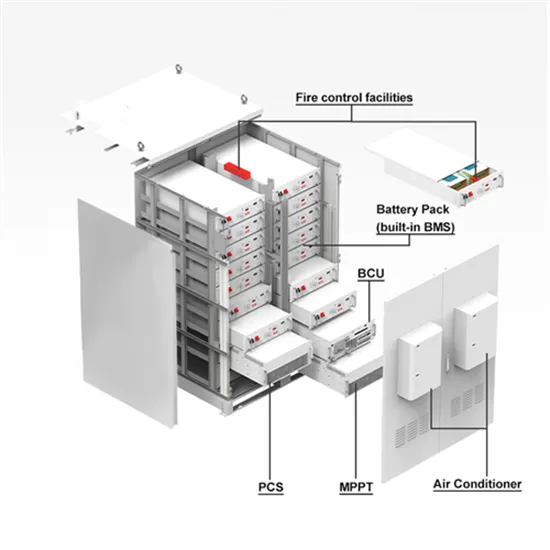

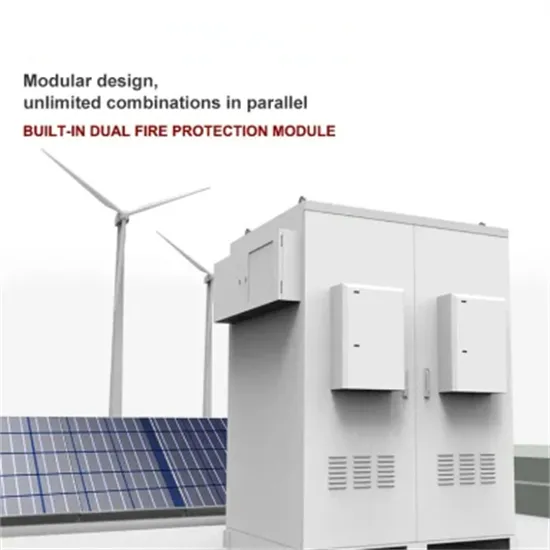

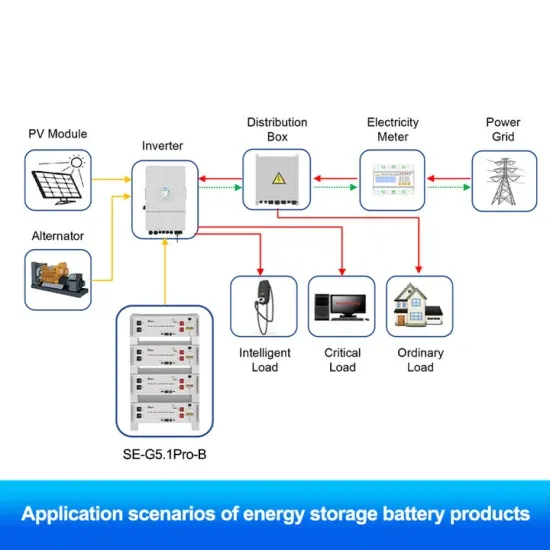

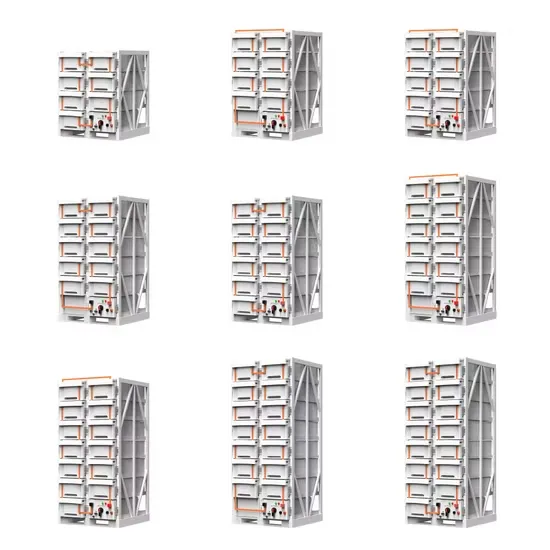

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.