Your Guide to Solar Panel Temperature and Efficiency

Solar modules collect energy from the sun. It seems logical to suggest that the more sun there is, the more energy the modules produce. In

Get Price

How to Calculate PV Cell Temperature

Understanding and calculating PV cell temperature is crucial for optimizing the design and performance of solar energy systems. This article explores the factors affecting PV

Get Price

Solar panel output: Standard Test Conditions vs. Real

In this article, we''ll talk about Standard Test Conditions (STC) and Nominal Operating Cell Temperature (NOCT). You''ll learn what you can

Get Price

Anthropology Flashcards | Quizlet

A solar module is a limited energy DC supply and has internal impedances that vary throughout the course of the day, depending primarily on the level of solar irradiance impinging on the

Get Price

Normal Operating Cell Temperature (NOCT): definition

Normal Operating Cell Temperature (NOCT) is a testing standard geared to the operational conditions of solar cells, defined as the temperature reached by open circuited cells in a

Get Price

Standard Test Conditions (STC) for Solar Panels

A definition and overview of Standard Test Conditions (STC) for solar panels, including cell temperature, solar irradiance, and air mass.

Get Price

Comprehensive characterisation and analysis of PV

We characterised and analysed the effect of irradiance, temperature, spectrally distributed irradiance and angle-of-incidence on the

Get Price

Standards for PV Modules and Components Recent

Working Group 2 (Modules) of TC82 has been active over this entire period, developing standards for PV modules. The following is a list of the IEC standards on PV modules (and devices)

Get Price

1 derating a pv array to a ptc ac rating consider a pv array rated

Question 1- Derating a PV Array to a PTC, AC Rating. Consider a PV array rated at 1 kW under standard test conditions. Module nominal operating cell temperature (NOCT) is

Get Price

PVsyst Cell Temperature Model

PVsyst users can also enter a NOCT (Nominal Operating Collector Temperature) in place of U values. The program then automatically calculates U values

Get Price

Standard Test Conditions (STC) of a Photovoltaic Panel

Outdoor measurements on PV panels and modules (or arrays) have to be performed under the actual conditions of irradiance, temperature

Get Price

Standard Test Conditions (STC) for Solar Panels

A definition and overview of Standard Test Conditions (STC) for solar panels, including cell temperature, solar irradiance, and air mass.

Get Price

Understanding Standard Test Conditions (STC) Solar

This case study highlights the importance of STC ratings, managing cell temperature, and considering real-world conditions for optimal solar PV

Get Price

Understanding STC In Solar Panels: PV Test Conditions Explained

Solar technicians will measure the solar panel temperature before measuring power output, voltages, and relevant currents. "What should we set the air mass coefficient for testing PV

Get Price

How to Calculate PV Cell Temperature

Understanding and calculating PV cell temperature is crucial for optimizing the design and performance of solar energy systems. This article

Get Price

What is NOCT (Normal Operating Cell Temperature)?

4. NOCT (Normal Operating Cell Temperature) is crucial for evaluating the long-term reliability and durability of solar modules. Higher

Get Price

Understanding PV System Standards, Ratings, and

Learn about PV module standards, ratings, and test conditions, which are essential for understanding the quality and performance of

Get Price

Understanding the Specifications of Solar Panels and

Specifications of the solar panel include details on the efficiency, wattage, temperature coefficients, and warranty.

Get Price

Understanding PV System Standards, Ratings, and Test Conditions

Learn about PV module standards, ratings, and test conditions, which are essential for understanding the quality and performance of photovoltaic systems.

Get Price

What is Solar Panel Temperature Coefficient?

Calculation of Temperature Coefficient Let us take an example, to calculate the power loss of a solar PV module. The ambient temperature in

Get Price

Photovoltaic module cell temperature estimation: Developing a

After creating expressions giving ambient temperature, solar radiation, wind speed and photovoltaic panel cell temperature, the validity of the obtained expressions was

Get Price

Understanding STC In Solar Panels: PV Test Conditions Explained

"What should the PV cell temperature be during a solar panel test?" The efficiency of solar panels depends on cell temperature. For example, a very hot 120°F solar panel will usually produce

Get Price

Standard Test Conditions (STC) of a Photovoltaic Panel

The standard test condition for a photovoltaic solar panel or module is defined as being 1000 W/m 2 (1 kW/m 2) of full solar irradiance when the panel and cells are at a

Get Price

PVsyst Cell Temperature Model

PVsyst users can also enter a NOCT (Nominal Operating Collector Temperature) in place of U values. The program then automatically calculates U values based on α = 0.9 and η m.

Get Price

Cells, Modules, Panels and Arrays

The performance of PV modules and arrays are generally rated according to their maximum DC power output (watts) under Standard Test Conditions (STC).

Get Price

Solar panel output: Standard Test Conditions vs. Real world

In this article, we''ll talk about Standard Test Conditions (STC) and Nominal Operating Cell Temperature (NOCT). You''ll learn what you can expect from your panels and

Get Price

Measuring the temperature coefficient of a PV module

Solar technicians will measure the solar panel temperature before measuring power output, voltages, and relevant currents. "What should we set the air

Get Price

Standard Test Conditions (STC) of a Photovoltaic Panel

The standard test condition for a photovoltaic solar panel or module is defined as being 1000 W/m 2 (1 kW/m 2) of full solar irradiance

Get Price

Understanding Standard Test Conditions (STC) Solar

This case study highlights the importance of STC ratings, managing cell temperature, and considering real-world conditions for optimal solar PV system performance.

Get Price

More related information

-

Photovoltaic cell module production project

Photovoltaic cell module production project

-

Double glass module working environment temperature

Double glass module working environment temperature

-

Photovoltaic cell module customs declaration

Photovoltaic cell module customs declaration

-

Export PV Module Ranking

Export PV Module Ranking

-

Swaziland photovoltaic cell module wholesale

Swaziland photovoltaic cell module wholesale

-

Photovoltaic cell module manufacturing in Tunisia

Photovoltaic cell module manufacturing in Tunisia

-

Photovoltaic cell module manufacturing in Uzbekistan

Photovoltaic cell module manufacturing in Uzbekistan

-

What is the Standard PV Module Project

What is the Standard PV Module Project

Commercial & Industrial Solar Storage Market Growth

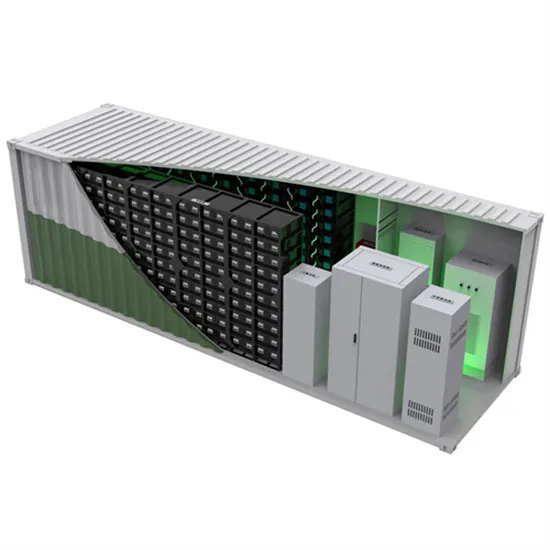

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

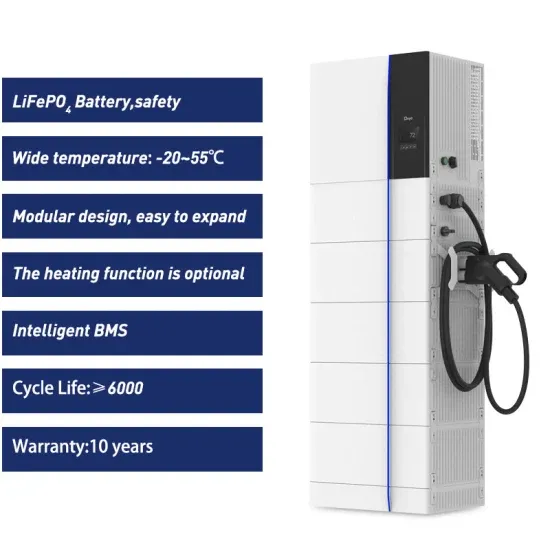

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.