How solar energy is produced? An In-Depth Overview

Solar energy production is diverse: There are two primary methods of solar energy production – photovoltaic solar cells and concentrated solar

Get Price

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal manufacturing exists, most solar

Get Price

Solar Energy Definition

What is Solar Energy? Solar energy is a renewable and sustainable form of power derived from the radiant energy of the sun. This energy is

Get Price

If a solar panel manufacturer wants to look at its total costs of

If a solar panel manufacturer wants to look at its total costs of production in the short run, which of the following would provide a useful starting point? A. Divide total costs into

Get Price

Solar Panel Manufacturing Process Explained | Anmak Solar

Solar panel manufacturing involves several key stages. Each stage is important for making sure the panels work well and last a long time. Here is an overview of the process:

Get Price

A breakdown of solar panel components and how they work

Learn how solar panels work with a detailed diagram and explanation of the components and process of converting sunlight into electricity.

Get Price

How to divide solar panels into several | NenPower

Depending on the installation site, solar panels can be grouped based on factors such as shading, orientation towards the sun, and local climate conditions. When solar panels

Get Price

Photovoltaic vs Solar Panels: Understanding the

Key Differences Between PV and Solar Thermal Panels While both PV and solar thermal panels harness energy from the sun, they serve different purposes

Get Price

How Much Energy Can Solar Panels Generate?

Explore how much energy solar panels generate, factors affecting their efficiency, and how to maximize solar power output for homes and businesses. Learn

Get Price

Examining the Environmental Impact of Solar Panels

What Needs to Change for Solar to Be a True Green Solution? While solar energy has significant benefits, it still has its downsides. To make it a true green solution, we need to

Get Price

Processes for the assembly and production of solar panels

In short, a number of specialists and 20-25 machines closely work together from cell to module. The process revolves around ten major steps, which divide into several sub-steps, to produce

Get Price

What are the Factors of Production? — OhMyEcon

The land resource can be divided into 2 categories: resources that are renewable and resources that are non-renewable. Renewable resources are ones that can be

Get Price

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get Price

How Are Solar Panels Manufactured Step-by-Step? A Clear

Discover the step-by-step journey of solar panel manufacturing, from high-purity silicon wafers to final assembly and quality testing. Explore key components like PV cells, tempered glass, and

Get Price

Solar Panel Output Calculator | Get Maximum Power

The Solar Panel Output Calculator is a highly useful tool for anyone looking to understand the total output, production, or power generation

Get Price

Solar Panel Manufacturing: A Step-by-Step Overview

In this guide, we will cover the basics of solar panel manufacturing — including the various components of a solar module, the photovoltaics manufacturing process, the

Get Price

How many MWh of solar energy comes from a MW of solar panels?

One of the most common questions in solar is: How much energy (megawatt hours / MWh) comes from 1 megawatt (MW) of solar power? The answer varies tremendously based

Get Price

Solar Panel Manufacturing : Process, Production Stages

Solar panel production involves several stages, including silicon processing, wafering, cell fabrication, module assembly, and testing. The process begins with silicon

Get Price

Solar Panel Manufacturing Process Explained

Solar panel manufacturing involves several key stages. Each stage is important for making sure the panels work well and last a long time.

Get Price

Solar Panel Production Process. A complete Guide on Solar?

From raw materials and assembly lines to safety testing and packaging, we''ll explore in-depth every aspect of the process that turns a simple material like silicon into a

Get Price

How is solar energy timed? | NenPower

2. SOLAR ANGLES AND THEIR IMPACT One of the essential components affecting solar energy timing is the angle of the sun''s rays as they impact solar panels. Solar

Get Price

How Solar Panels Are Made: A Comprehensive Guide

Solar panels are at the forefront of the renewable energy revolution, providing a sustainable and environmentally friendly way to generate electricity. The production of solar panels is a

Get Price

How much does a solar panel actually produce? | Greenwood

If a panel has a total surface area of 2 m2 and is rated at 400 watts, it has an efficiency of 20% Area of panel is determined and is divided into its watt rating, 400/2000mm= 20% As there are

Get Price

Solar Panel Output Calculator

Use this solar panel output calculator to find out the total output, production, or power generation from your solar panels per day, month, or in

Get Price

How solar energy is produced? An In-Depth Overview

Solar energy production is diverse: There are two primary methods of solar energy production – photovoltaic solar cells and concentrated solar power. Both methods offer unique

Get Price

How to divide solar panels into several | NenPower

Depending on the installation site, solar panels can be grouped based on factors such as shading, orientation towards the sun, and local

Get Price

Solar panels are divided into several levels

Solar panels are usually arranged in groups called arrays or systems. A photovoltaic system consists of one or more solar panels,an inverter that converts DC electricity to alternating

Get Price

Solar Panel Production Process. A complete Guide on

From raw materials and assembly lines to safety testing and packaging, we''ll explore in-depth every aspect of the process that turns a

Get Price

Solar Panel Manufacturing: A Step-by-Step Overview

In this guide, we will cover the basics of solar panel manufacturing — including the various components of a solar module, the photovoltaics

Get Price

Solar Panel Manufacturing : Process, Production

Solar panel production involves several stages, including silicon processing, wafering, cell fabrication, module assembly, and testing. The

Get Price

6 FAQs about [The production of solar panels can be divided into]

What are the different aspects of solar panel production?

In future guides, we will cover in detail the various aspects of solar panel production, including the parts of a solar panel, photovoltaic manufacturing, assembling a solar production line, the cost of production, and the benefits of automation.

What are the basics of solar panel manufacturing?

The basics of solar panel manufacturing are very important when it comes to the solar panel production business. Selecting the appropriate equipment is crucial to ensure top-notch outcomes. In particular, a production line requires various types of tools and machines, including soldering tools, wire strippers, drills, and testing equipment.

How are solar panels made?

The key components in solar PV manufacturing include silicon wafers, solar cells, PV modules, and solar panels. Silicon is the primary material used, which is processed into wafers, then assembled into solar cells and connected to form solar modules.

What is solar panel production?

Solar panel production involves the manufacture of photovoltaic cells and modules that convert sunlight into electricity. Silicon is at the heart of solar cell technology as it is used to create semiconductors which are then used to form photovoltaic cells or PV cells.

What are the stages involved in solar panel production?

The stages involved in solar panel production are: Silicon processing: The raw silicon is melted and purified to create high-purity silicon ingots or wafers. Wafering: The silicon ingots or wafers are cut into thin slices, which are then processed into solar cells.

How is solar energy produced?

Solar energy is produced through the conversion of sunlight into electricity or heat. This process involves using various technologies such as solar panels and solar thermal systems. What are photovoltaic (PV) panels?

More related information

-

The production of solar panels can be divided into

The production of solar panels can be divided into

-

How long will it take for solar panels to reach full production

How long will it take for solar panels to reach full production

-

Synthesis and production of solar panels

Synthesis and production of solar panels

-

Solar panels are divided into several levels

Solar panels are divided into several levels

-

Automated production of solar panels

Automated production of solar panels

-

Uruguay makes solar panels

Uruguay makes solar panels

-

12v low pressure water pump inverter can be connected to solar panels

12v low pressure water pump inverter can be connected to solar panels

-

Is there anyone who wants photovoltaic panels for sale as solar panels

Is there anyone who wants photovoltaic panels for sale as solar panels

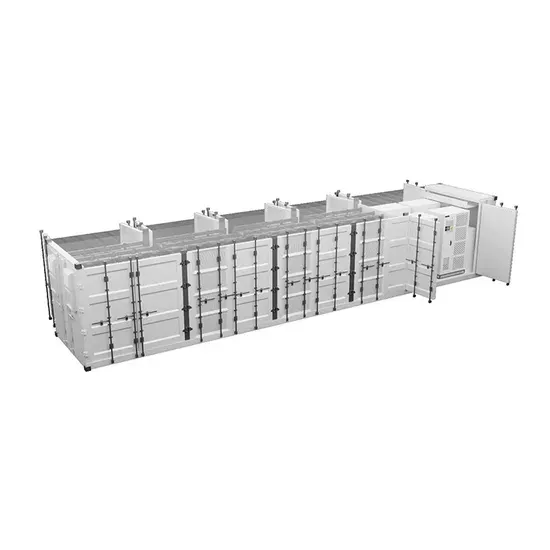

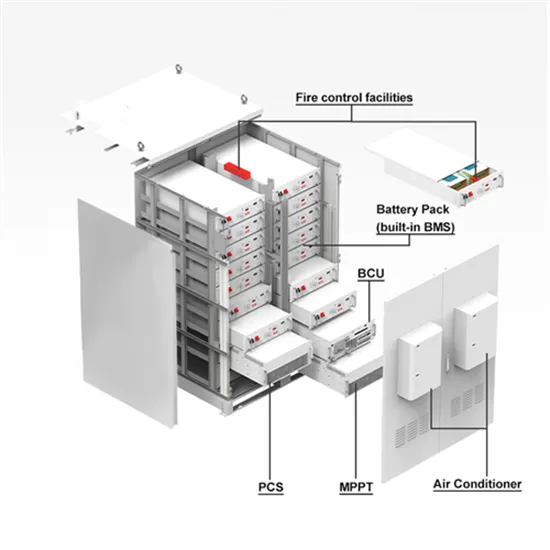

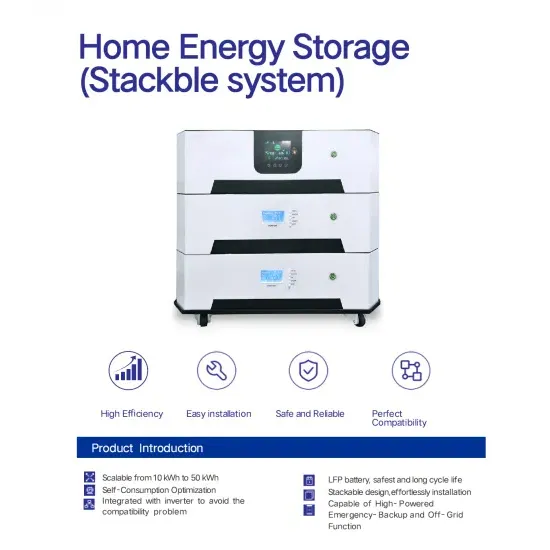

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

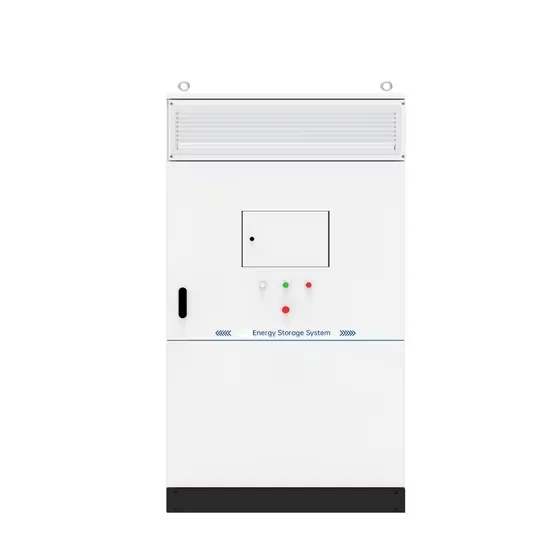

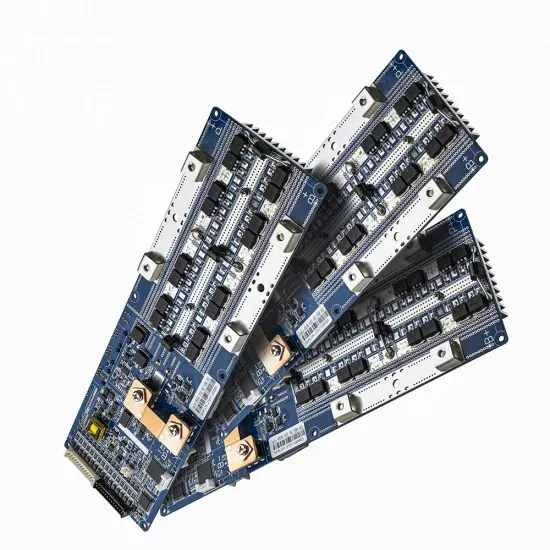

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.