Materials and methods for cost-effective fabrication of perovskite

The scalable and cost-effective synthesis of perovskite solar cells is dependent on materials chemistry and the synthesis technique. This Review discusses these considerations,

Get Price

Solar energy

Solar energy is a CO2-free renewable energy source. Solar power is an unlimited source of energy. Read more about solar energy production and or solar plants.

Get Price

How Solar Panels Are Made

Join us as we unveil the intricate process behind solar panels, revealing the materials, craftsmanship, and technology that make turning sunlight into electricity possible for

Get Price

The Solar Panel Manufacturing Process

Solar panels, the fundamental components of any solar energy system, harness the power of the sun to produce electricity. But how are these technologically advanced devices made? In this

Get Price

Photovoltaics Manufacturing, Polysilicon | Solar Power

PV manufacturing includes three distinct processes: 1. Manufacturing silicon (polysilicon or solar-grade), 2. wafers (mono- or polycrystalline) and 3. cells and modules (crystalline and thin-film).

Get Price

DOI: 10.1515/adms 2015 0024

efficiency of solar panels. In addition, graphene has a low coefficient of light absorption 2.3% which indicates that is an almost comp etely transparent material. In fact, it means that solar

Get Price

How Are Solar Panels Made? Detailed Facts And

Solar panels are a typical example of man-made technological marvels. They should provide clean energy for generations. How Are Solar

Get Price

Solar Panel Manufacturing : Process, Production

Understanding the manufacturing processes of solar panels is essential for renewable energy enthusiasts. This comprehensive article covers

Get Price

How Are Solar Panels Made Step by Step

Here, we''ll guide you through each step of making a solar panel. Making solar panels starts by turning raw materials, like silica sand, into powerful photovoltaic modules.

Get Price

The Solar Panel Manufacturing Process

Solar panels, the fundamental components of any solar energy system, harness the power of the sun to produce electricity. But how are these technologically

Get Price

Solar-Thermal Ammonia Production (STAP)

The Solution A solar thermochemical looping technology to produce and store nitrogen from air for the subsequent production of ammonia via a novel synthesis pathway

Get Price

Silicon-based photovoltaic solar cells

An overview is given of materials and manufacturing issues throughout the supply chain of the solar silicon photovoltaic industry. The historical evolution of the industry and

Get Price

Third-Generation Photovoltaic Solar Cells | 6 | Synthesis,

The growing demand for advanced materials and innovative technology for new energy devices has fueled the need for "green" production and energy/cost savings. Solar cells, an efficient

Get Price

What is the Manufacturing Process of Solar Panels?

Solar panel manufacturing is a complex and intricate process involving several critical stages, each contributing to the efficiency and functionality of the final product. Here''s a

Get Price

How Solar Panels Are Made: Step-by-Step Manufacturing Process

Discover how solar panels are made, from raw silicon to rooftop-ready tech. Learn about every step of the solar panel manufacturing process at Inter Solar.

Get Price

Synthesis Gas Production by Rapid Solar Thermal

The novel approach taken by the authors uses concentrated solar energy to efficiently achieve temperatures where conversion and selectivity of gasification are high (1000°C – 1200 °C).

Get Price

Solar Panel Manufacturing : Process, Production Stages

Understanding the manufacturing processes of solar panels is essential for renewable energy enthusiasts. This comprehensive article covers the main aspects of solar

Get Price

How Are Solar Panels Made Step by Step

Here, we''ll guide you through each step of making a solar panel. Making solar panels starts by turning raw materials, like silica sand, into

Get Price

How Are Solar Panels Made? Detailed Facts And Walkthrough

Solar panels are a typical example of man-made technological marvels. They should provide clean energy for generations. How Are Solar Panels Made? How are solar

Get Price

What is the Manufacturing Process of Solar Panels?

Solar panel manufacturing is a complex and intricate process involving several critical stages, each contributing to the efficiency and

Get Price

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes

Get Price

How Solar Panels Are Made

Join us as we unveil the intricate process behind solar panels, revealing the materials, craftsmanship, and technology that make turning

Get Price

Simple synthesis of weather-resistant and self-cleaning anti

Transparent self-cleaning coatings have garnered significant attention for their promising prospects in outdoor applications, particularly in solar panels and high-end optical

Get Price

Driving Chemical Transformations Through the Power

Researchers combine solar energy, electrochemistry, and thermal catalysis to remove the need for fossil fuel-driven chemical conversions.

Get Price

DOE ExplainsSolar Fuels

Energy production via solar fuels could recreate the starting chemicals, forming a closed cycle that minimizes unwanted by-products.

Get Price

Progress in Development of Photocatalytic Processes for Synthesis

With photovoltaics becoming a mature, commercially feasible technology, society is willing to allocate resources for developing and deploying new technologies based on using solar light.

Get Price

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get Price

How Solar Panels Are Made: A Comprehensive Guide

This article delves into the specifics of how solar panels are made, detailing the technology, minerals, production line, and each component involved in creating these marvels of modern

Get Price

Photochemical Systems for Solar-to-Fuel Production

The photochemical system, which utilizes only solar energy and H2O/CO2 to produce hydrogen/carbon-based fuels, is considered a promising approach to reduce CO2

Get Price

Green synthesis of TiO2 nanoparticles for enhanced

Future directions include exploring diverse natural extracts for TiO 2 synthesis, refining fabrication techniques, and developing novel dyes

Get Price

6 FAQs about [Synthesis and production of solar panels]

What is the manufacturing process of solar panels?

Understanding this process is crucial for advancing sustainable energy solutions. The manufacturing process of solar panels primarily involves silicon cell production, panel assembly, and quality assurance.

How are solar panels produced?

Solar panel manufacturing is a complex, multi-step process, involving a range of scientific disciplines and high precision procedures to turn raw materials into energy-generating devices. Let’s analyze each step of the production process.

What is the first step in solar panel manufacturing process?

The first step in solar panel manufacturing process is purifying quartz sand to extract high-grade silicon, which is the base for solar cells. Why does the type of silicon matter?

How do you make a solar panel?

Here, we’ll guide you through each step of making a solar panel. Making solar panels starts by turning raw materials, like silica sand, into powerful photovoltaic modules. This process includes melting silicon ingots to creating the final solar panels. Leading the charge in making these clean energy solutions is Fenice Energy from India.

How long does it take to make solar panels?

The entire solar panel manufacturing process, from silicon wafer production to the final panel assembly, typically takes about 3-4 days. This includes cutting silicon wafers, assembling cells, encapsulating them, and quality testing before shipping.

What are the stages involved in solar panel production?

The stages involved in solar panel production are: Silicon processing: The raw silicon is melted and purified to create high-purity silicon ingots or wafers. Wafering: The silicon ingots or wafers are cut into thin slices, which are then processed into solar cells.

More related information

-

The production of solar panels can be divided into

The production of solar panels can be divided into

-

The production of solar panels is divided into two categories

The production of solar panels is divided into two categories

-

How long will it take for solar panels to reach full production

How long will it take for solar panels to reach full production

-

Colombian solar panels 24W photovoltaic charging panels single

Colombian solar panels 24W photovoltaic charging panels single

-

Can solar photovoltaic panels generate heat

Can solar photovoltaic panels generate heat

-

Can solar photovoltaic panels generate enough electricity for home use

Can solar photovoltaic panels generate enough electricity for home use

-

Popularize solar panels

Popularize solar panels

-

Does the photovoltaic industry need solar panels

Does the photovoltaic industry need solar panels

Commercial & Industrial Solar Storage Market Growth

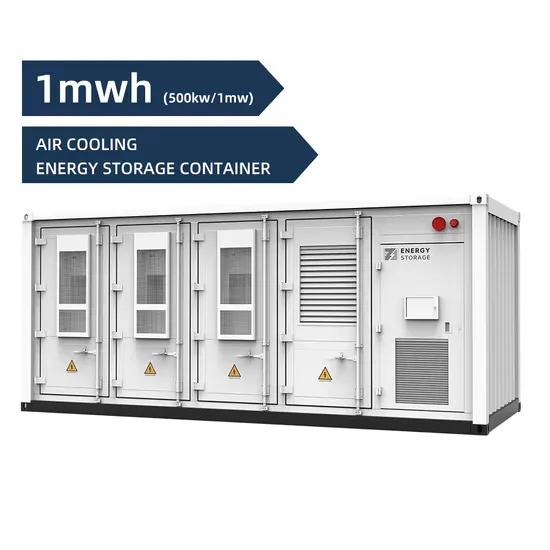

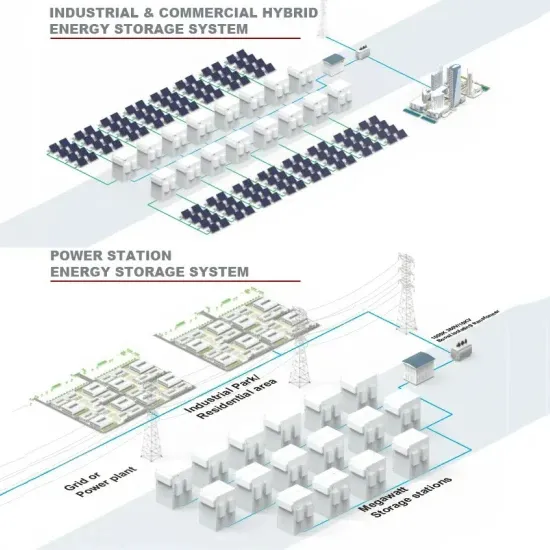

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.