Custom Cabinet Manufacturing Process

Want to see our custom cabinet manufacturing process? Look no further! NGY Group, Inc. and Parriott Wood have made notable investments in top-of-the-line mac

Get Price

The Manufacturing Process of Kitchen Cabinets 2025

Knowing more about the kitchen cabinet manufacturing process helps you make an informed decision when choosing a kitchen cabinet. Click

Get Price

Battery Cabinets and Enclosures Manufacture

Get your battery charging cabinets from the leading fabricator. Depend on Openex to eliminate supply chain delays and deliver quality cabinets—from small to extra-large.

Get Price

Battery Module: Manufacturing, Assembly and Test Process Flow.

In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell Finishing. Article Link In

Get Price

Home

The current production capacity of our li-ion battery factory is 6GWh and 20Gwh is in construction, and there are approximately 1600 employees, including 580

Get Price

LION ENERGY DEVELOPING U.S.-BASED

Lion Energy announced it is developing a cutting-edge manufacturing line at its Utah facility for battery rack modules (BRM) and large

Get Price

Clean/Dry Rooms for Lithium Ion Battery Manufacturing

In a lithium-ion battery, you''ll find pressurized containers that house a coil of metal and a flammable, lithium-containing liquid. The manufacturing process creates tiny pieces of metal

Get Price

Complete Guide for Battery Enclosure

Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or cabinet is always a

Get Price

From Raw Materials to Reliable Power: Inside the Energy Storage

Ever wondered what goes into creating those sleek battery cabinets powering solar farms or backup systems? The energy storage equipment production process is like baking a multilayer

Get Price

SMART E-BIKE BATTERY SWAPPING CABINET | PRODUCTION

Learn about how the collaboration between WeiMiao and China Tower Corporation Limited has enabled the production of state-of-the-art e-bike battery swapping cabinets. This video shows

Get Price

Battery cells to high-voltage battery cabinets! Factory live

🔋⚡Explore the core production line of the energy storage factory! 🏭From battery cell sorting, module welding to cabinet integration, the precision manufact

Get Price

Top 6 Electrical Cabinet Manufacturers in Vietnam

Explore the top 6 electrical cabinet manufacturers in Vietnam, including Eabel and 3C Electric, offering customized, high-quality solutions for

Get Price

CATL Battery Factory • CÉH

CATL Battery Factory The investment is the largest European battery plant to date by Chinese company CATL, being built in Debrecen, in the Southern

Get Price

battery cabinet production, protect the batteries

Dear friend, this video has show how to produce the battery cabinet. more step are control by computer, it can ensure the correct size for the battery cabinet. if you has any question about the

Get Price

The Battery Cell Factory of the Future | BCG

To reduce conversion costs, cell makers need to retrofit or design factories with the latest advancements in automation and artificial intelligence, along with making proven lean

Get Price

Welcome to Gamma Factory for Metal Ind.

Company Profile Gamma Factory For Metal Industries located in Saudi Arabia – Riyadh. Gamma Specialized in manufacturing of 19" Networking and Telecom Cabinets, Sound Proof Canopies

Get Price

BC Series UPS Battery Cabinets

ZincFive BC Series UPS Battery Cabinets are the world''s first NiZn battery energy storage solution with backward and forward compatibility with

Get Price

Factory Infrastructure for Battery Manufacturing | PDF

The document outlines the infrastructure and design considerations for battery manufacturing facilities, emphasizing the importance of process-driven design

Get Price

How AZE Systems Manufactures BESS Battery Energy Storage

Manufacturing a BESS cabinet requires a combination of advanced engineering, precise manufacturing, and rigorous testing. By following the steps outlined above, you can

Get Price

Battery cells to high-voltage battery cabinets! Factory live production

🔋⚡Explore the core production line of the energy storage factory! 🏭From battery cell sorting, module welding to cabinet integration, the precision manufact

Get Price

Battery Manufacturing Process: Materials, Production

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Get Price

Battery Cabinets and Enclosures Manufacture

Get your battery charging cabinets from the leading fabricator. Depend on Openex to eliminate supply chain delays and deliver quality cabinets—from

Get Price

Complete Guide for Battery Enclosure

Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or

Get Price

Energy Storage All-in-One Cabinet Factory

Our Energy Storage All-in-One Cabinet Factory integrates cutting-edge battery technology, intelligent energy management, and robust safety features to deliver seamless power solutions.

Get Price

Battery Manufacturing Process: Materials, Production & Test

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process,

Get Price

Lion Energy building out large energy storage cabinet

Battery manufacturer Lion Energy is developing a manufacturing line at its Utah facility for battery rack modules (BRM) and large energy

Get Price

Lion Energy building out large energy storage cabinet production

Battery manufacturer Lion Energy is developing a manufacturing line at its Utah facility for battery rack modules (BRM) and large energy storage cabinet assembly.

Get Price

Exploring the World of Cabinet Type Energy Storage Battery

At the core of every cabinet type energy storage battery factory lies a commitment to cutting-edge technology and meticulous design. These facilities are designed to optimize

Get Price

New Energy Battery Production Line

Xiaowei specialize in the research, development and sales of battery technology (battery production machine) manufacturing processes and equipment, and can customize, layout and

Get Price

6 FAQs about [Factory battery cabinet production]

What is the battery manufacturing process?

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from material selection to the final product’s assembly and testing.

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

How do battery cell producers prepare for the factory of the future?

To navigate these challenges and capitalize on the benefits of the factory of the future, battery cell producers should take the following steps: Evaluate optimization levers. Assess the business maturity and financial implications of optimization measures across each dimension of the factory of the future. Assess fit.

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

How will the factory of the future improve battery production?

This reduces reliance on dedicated maintenance teams and prevents deterioration of equipment by maintaining it in optimal condition. We estimate that the factory of the future will reduce conversion costs in battery cell production by 20% to 30% from the 2024 baseline. (See Exhibit 5.)

What are the parts of a battery storage cabinet?

Let’s look at the most common parts: Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels. Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure.

More related information

-

Lithium battery station cabinet factory production standards

Lithium battery station cabinet factory production standards

-

What production equipment does the lithium battery station cabinet need

What production equipment does the lithium battery station cabinet need

-

How much does battery cabinet production equipment cost

How much does battery cabinet production equipment cost

-

Ess energy storage battery production factory

Ess energy storage battery production factory

-

Belarusian energy storage cabinet battery production

Belarusian energy storage cabinet battery production

-

Battery cabinet production in Sierra Leone

Battery cabinet production in Sierra Leone

-

Energy storage cabinet battery production plant system

Energy storage cabinet battery production plant system

-

Cambodia Energy Storage Cabinet Battery Factory

Cambodia Energy Storage Cabinet Battery Factory

Commercial & Industrial Solar Storage Market Growth

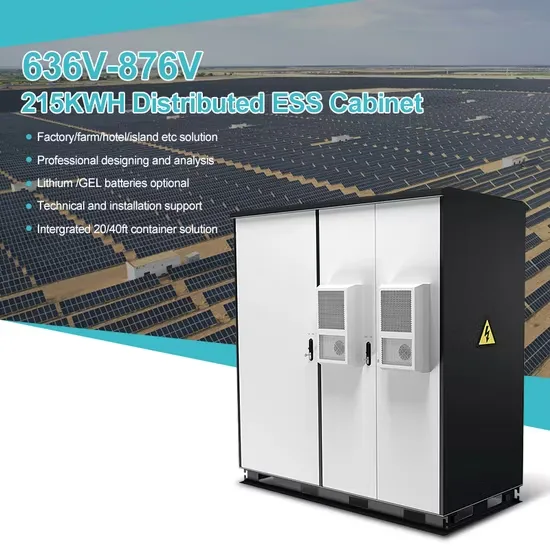

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.