Definition of Series and Parallel Connection of Lithium

Lithium battery pack technique refers to the processing, assembly and packaging of lithium battery pack. The process of assembling lithium cells

Get Price

Batteries in Series vs Parallel: Which is Better?

Do you know the difference between batteries in series vs parallel? Find out how to connect batteries in series or parallel & discover which one''s best for you!

Get Price

How to Connect & Charge Batteries in Series / Parallel

If you want to know about charging batteries in series and parallel then you have probably asked or are wondering what the advantage is of

Get Price

Lithium Series, Parallel and Series and Parallel

Connecting multiple lithium batteries into a string of batteries allows us to build a battery bank with the potential to operate at an increased voltage, or with increased capacity and runtime, or both.

Get Price

All Things You Need to Know about Lithium Battery

Do not let lithium batteries with different voltages in series. Due to the problem of consistency of lithium batteries, they are grouped in series under the same

Get Price

Connecting batteries in series – BatteryGuy

There are two ways to wire batteries together, parallel and series. The illustrations below show how these set wiring variations can produce

Get Price

Series and Parallel, which is the first when assembling lithium

A series-first then parallel battery pack requires more sensors and wiring, with more BMS channels, resulting in higher costs. In contrast, a parallel-first then series

Get Price

Ultimate Guide of LiFePO4 Lithium Batteries in Series & Parallel

Unlock the ultimate guide to using LiFePO4 lithium batteries in series and parallel. Learn configurations, benefits, and tips for optimal performance!

Get Price

Batteries in Series and Batteries in Parallel

Key learnings: Battery Cells Definition: A battery is defined as a device where chemical reactions produce electrical potential, and multiple

Get Price

Helpful Guide to Lithium Batteries in Parallel and Series

Understand how to connect lithium batteries in parallel and series. Get practical tips and avoid common pitfalls. Start optimizing your battery setup today!

Get Price

Batteries in Series vs Parallel: Which is Better?

Do you know the difference between batteries in series vs parallel? Find out how to connect batteries in series or parallel & discover which one''s best for you!

Get Price

Multi-fault diagnosis for series-connected lithium-ion battery pack

This section shows a multi-fault diagnosis procedure for a series-connected battery pack based on parallel PCA-KPCA, as shown in Fig. 2. The multi-fault here refers to different

Get Price

Safety Tips for Connecting Batteries in Series and

Ensure safety when connecting a battery in series and parallel. Learn about risks like overcharging, thermal runaway, and mismatched cells,

Get Price

Connecting cells in series and then parallel or opposite

Connect cells in pairs in parallel, and then connect 13 pairs in series. Which way should I use and why? I found this answer that suggest that the way (1) is safer (but the

Get Price

Parallel then Series or Series then Parallel

All of the cells working in parallel are joined together in groups and then these are joined in series. This approach gives more flexibility for very

Get Price

Series and Parallel, which is the first when assembling lithium battery

A series-first then parallel battery pack requires more sensors and wiring, with more BMS channels, resulting in higher costs. In contrast, a parallel-first then series

Get Price

Battery Packs In Series Or Parallel: Key Differences And Wiring

Series connections require connecting the positive terminal of one battery to the negative terminal of the next, while parallel connections connect all positive terminals together

Get Price

Parallel then Series or Series then Parallel

All of the cells working in parallel are joined together in groups and then these are joined in series. This approach gives more flexibility for very large packs. The cells are wire

Get Price

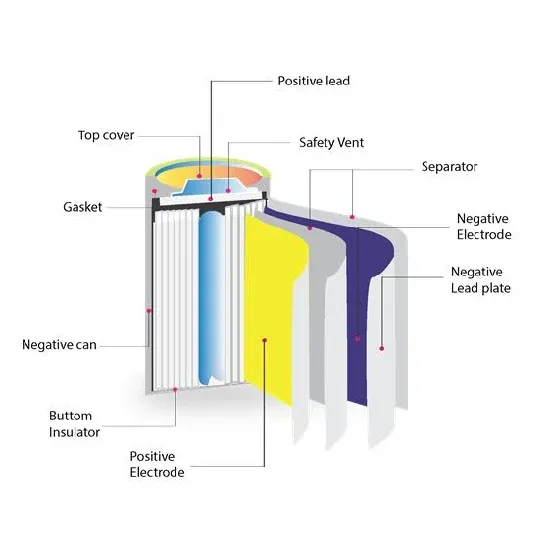

Definition of Series and Parallel Connection of Lithium Batteries

Lithium battery pack technique refers to the processing, assembly and packaging of lithium battery pack. The process of assembling lithium cells together is called PACK, which

Get Price

Can You Mix Different Capacity Lithium Batteries?

If you do not connect the batteries when they have the same state of charge (voltage level), then the inrush current can blow your fuses and

Get Price

All Things You Need to Know about Lithium Battery Series, Parallel

Do not let lithium batteries with different voltages in series. Due to the problem of consistency of lithium batteries, they are grouped in series under the same system (such as ternary or lithium

Get Price

6 FAQs about [Lithium battery pack first connected in series then in parallel]

What are the Connection modes of a lithium battery pack?

The typical connection modes of a lithium battery pack are connecting first in parallel and then in series, first in series and then in parallel, and finally, mixing together. Lithium battery pack for pure electric buses is usually connected first in parallel and then in series.

Can lithium-ion batteries be connected in parallel or in series?

Connecting lithium-ion batteries in parallel or in series is not as straightforward as a simple series-parallel connection of circuits. To ensure the safety of both the batteries and the individual handling them, several important factors should be taken into consideration.

How to connect a lithium battery in series?

) First connect in series according to the capacity of the lithium battery cell, such as 1/3 of the capacity of the entire group, and finally connect in parallel, which reduces the probability of failure of the large-capacity lithium battery module; first connect in series and then it is of great help to the consistency of the lithium battery pack.

Why are lithium batteries connected in series?

Lithium batteries are connected in series when the goal is to increase the nominal voltage rating of one individual lithium battery - by connecting it in series strings with at least one more of the same type and specification - to meet the nominal operating voltage of the system the batteries are being installed to support.

What is a series parallel battery connection?

Series-parallel. That's not wiring your batteries in both series and parallel. That would short your battery system! A series-parallel connection is when you wire several batteries in series. Then, you create a parallel connection to another set of batteries in series. By doing this, you can increase both voltage and capacity.

Why do we connect multiple lithium batteries to a string of batteries?

Connecting multiple lithium batteries into a string of batteries allows us to build a battery bank with the potential to operate at an increased voltage, or with increased capacity and runtime, or both.

More related information

-

How many amperes are there in a 12v lithium battery pack with 3 series and 8 parallel batteries

How many amperes are there in a 12v lithium battery pack with 3 series and 8 parallel batteries

-

10 series and 1 parallel lithium battery pack

10 series and 1 parallel lithium battery pack

-

Series lithium battery pack single cell voltage

Series lithium battery pack single cell voltage

-

Two lithium battery packs connected in parallel

Two lithium battery packs connected in parallel

-

Series and parallel connection of lithium battery packs

Series and parallel connection of lithium battery packs

-

Single charging of a series lithium battery pack

Single charging of a series lithium battery pack

-

Fengyu rechargeable lithium battery pack

Fengyu rechargeable lithium battery pack

-

Lithium battery pack maximum output current

Lithium battery pack maximum output current

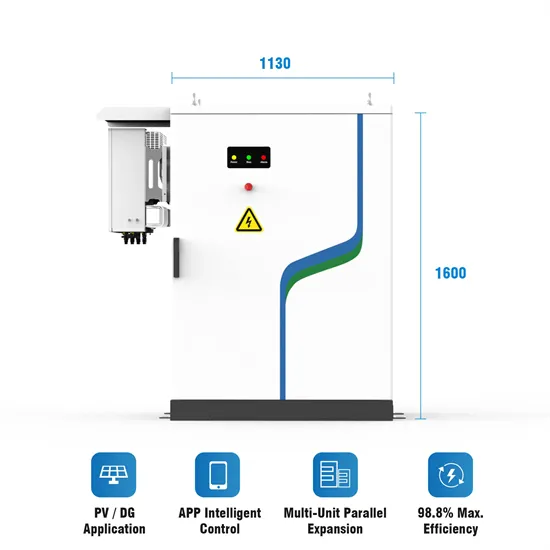

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.