BU-302: Series and Parallel Battery Configurations

Some packs may consist of a combination of series and parallel connections. Laptop batteries commonly have four 3.6V Li-ion cells in series to achieve a

Get Price

Battery Voltage Explained: Nominal, Charged, Minimum, and Cut

When selecting a lithium-ion battery pack, understanding its voltage characteristics is crucial for ensuring optimal performance and longevity. Three key voltage terms define a

Get Price

What Are Battery Cells, Battery Modules, And Battery

The process of assembling lithium battery cells into groups is called PACK, which can be a single battery or a battery module connected in

Get Price

How To Wire Lithium Batteries In Series to Increase

In this article, we will explain why you would want to wire lithium-ion batteries in series, how you wire them in series and how to charge battery

Get Price

Cells Per Battery Calculator

The Cells Per Battery Calculator is a tool used to calculate the number of cells needed to create a battery pack with a specific voltage and

Get Price

Lithium Batteries in series or parallel: What is the difference?

Lithium batteries in series: the voltage is added, the capacity remains unchanged, and the internal resistance increases. Lithium batteries in parallel: the voltage remains the same, the capacity

Get Price

How to Calculate the Number of Lithium Batteries in

Parallel voltage: The 2000mAh single battery can be assembled into a battery pack with a capacity of 2* (N)Ah as needed (N: number of single batteries)

Get Price

Lithium Series, Parallel and Series and Parallel

Introduction Lithium battery banks using batteries with built-in Battery Management Systems (BMS) are created by connecting two or more batteries together to support a single

Get Price

Battery pack calculator : Capacity, C-rating, ampere, charge and

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

Get Price

Helpful Guide to Lithium Batteries in Parallel and Series

During series charging, if the voltage of a single cell reaches the overcharge protection voltage, the battery management system will cut off the entire series charging circuit

Get Price

Battery configurations (series and parallel) and their protections

The series configuration is used where the voltage of a single cell is insufficient. The series configuration is achieved by connecting a cell''s positive to another cell''s negative,

Get Price

Lithium Battery Voltage Guide: Types, Charging

Lithium battery voltage impacts power and compatibility. This article covers Li-ion, LiPo, LiFePO4, and 18650 voltages, plus charging and

Get Price

What is the difference between a single-cell and multi-cell lithium

The most obvious difference between single-cell and multi-cell lithium polymer batteries is their structure. A single-cell battery consists of a single lithium-ion cell, while a

Get Price

Ultimate Guide to Battery Voltage Chart

Charging to 29.2V means that the battery pack is fully charged, and each cell reaches 3.65V at this moment. Discharging to 20V means that the battery pack has been fully

Get Price

Cells in Series and Pack Voltage

The maximum to minimum voltage swing increases as we increase the number of cells in series. The maximum voltage is important as the

Get Price

Connecting batteries in series – BatteryGuy

This means that if you have two batteries in series of the same voltage and amp hour capacity that you have been using for a while, but

Get Price

Ultimate Guide to Lithium-Ion Battery Voltage Chart

The recommended voltage range for short-term storage of lithium-ion batteries is 3.0 to 4.2 volts per cell in series. For long-term storage, lithium-ion batteries should be stored

Get Price

Battery configurations (series and parallel) and their

The series configuration is used where the voltage of a single cell is insufficient. The series configuration is achieved by connecting a cell''s

Get Price

Learn about BMS and Battery Pack: Cell Voltage Monitoring

The BMS (battery management system) monitors the battery cells in various aspects and controls the status of the battery pack. See cell voltage monitoring basics.

Get Price

Lithium Ion / Polymer Single Cells

Warnings Li-Ion battery is dangerous. Must read safety instructions before buying / using Li-ion / Polymer battery and packs Never use Li-Ion battery pack without PCB (protection circuit

Get Price

Lithium-Ion Battery Voltage: How Many Volts And Types

When connected in series, the total voltage increases by 3.7 volts for each cell. This configuration allows for different battery pack designs. Lithium-ion batteries are

Get Price

Series and Parallel Configuration of Lithium Battery

The single-cell configuration is the simplest battery pack. Typical these configuration are available in mobile phones and tablets with one 3.7V

Get Price

Ultimate Guide to Battery Voltage Chart

Charging to 29.2V means that the battery pack is fully charged, and each cell reaches 3.65V at this moment. Discharging to 20V means that

Get Price

Battery Cell Balancing: What to Balance and How

Simultaneous multi-cell balancing makes decision on which cells have to by bypassed under considerations of the entire pack and not only neighboring cells as it is the case with

Get Price

optimal series and parallel configurations for 18650 and 21700

In a series configuration, batteries are connected end-to-end, with the positive terminal of one cell connected to the negative terminal of the next. This arrangement has the following effects:

Get Price

Helpful Guide to Lithium Batteries in Parallel and Series

During series charging, if the voltage of a single cell reaches the overcharge protection voltage, the battery management system will cut off the

Get Price

Lithium Batteries in series or parallel: What is the

Lithium batteries in series: the voltage is added, the capacity remains unchanged, and the internal resistance increases. Lithium batteries in parallel: the voltage

Get Price

optimal series and parallel configurations for 18650 and 21700 lithium

In a series configuration, batteries are connected end-to-end, with the positive terminal of one cell connected to the negative terminal of the next. This arrangement has the following effects:

Get Price

Cells in Series and Pack Voltage

The maximum to minimum voltage swing increases as we increase the number of cells in series. The maximum voltage is important as the charging system requirements need

Get Price

How to Calculate the Number of Lithium Batteries in Series or

Parallel voltage: The 2000mAh single battery can be assembled into a battery pack with a capacity of 2* (N)Ah as needed (N: number of single batteries) Such as 4000mAh, 6000mAh,

Get Price

Series and Parallel Configuration of Lithium Battery

The single-cell configuration is the simplest battery pack. Typical these configuration are available in mobile phones and tablets with one 3.7V Lithium-ion cell.

Get Price

How to Calculate Lithium-Ion Battery Pack Capacity

Learn the simple steps to calculate a lithium-ion battery pack''s capacity and runtime accurately in this comprehensive guide.

Get Price

More related information

-

Single charging of a series lithium battery pack

Single charging of a series lithium battery pack

-

Lithium battery pack parallel voltage balance

Lithium battery pack parallel voltage balance

-

Lithium battery pack first connected in series then in parallel

Lithium battery pack first connected in series then in parallel

-

Lithium battery replacement single string battery pack

Lithium battery replacement single string battery pack

-

Pack lithium battery single layer

Pack lithium battery single layer

-

Lithium battery pack 1000V high voltage charging and discharging

Lithium battery pack 1000V high voltage charging and discharging

-

Minimum voltage of lithium battery pack

Minimum voltage of lithium battery pack

-

36v lithium battery pack voltage

36v lithium battery pack voltage

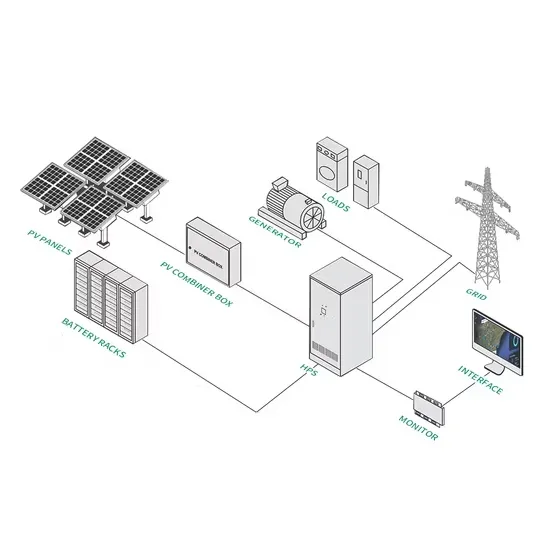

Commercial & Industrial Solar Storage Market Growth

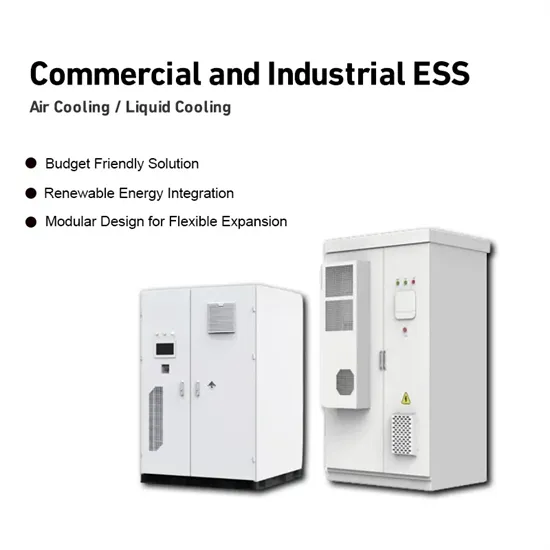

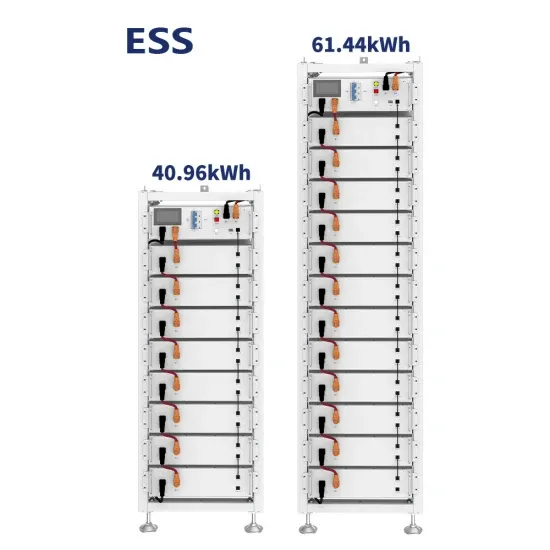

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

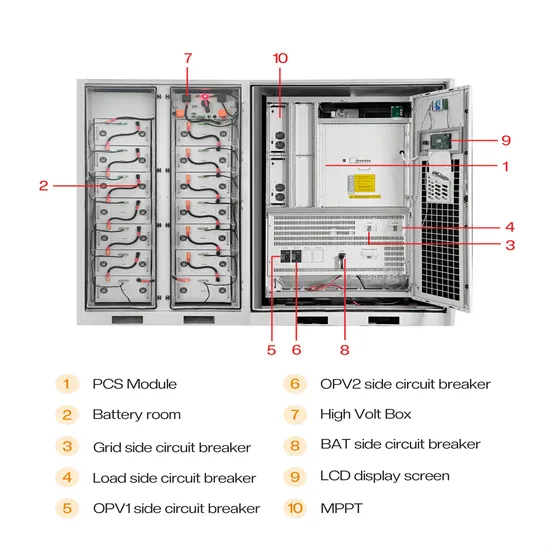

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.