What is a PV Inverter?

Centralized VS String VS Micro VS Power Optimizers: Comparison of the 4 Types of PV Inverters Centralized inverters are well-suited for large

Get Price

Utility-Scale PV | Electricity | 2024 | ATB | NREL

Plant costs are represented with a single estimate per innovation scenario because CAPEX does not correlate well with solar resources. For the 2024

Get Price

Why Laminated Inverter Busbar Cuts Inverter Cost

2 days ago· According to the China Photovoltaic Industry Association, inverter costs account for 18% of PV system costs in 2025. Reducing inverter costs is key for renewable energy

Get Price

Solar Installed System Cost Analysis | Solar Market Research

NREL''s bottom-up cost modeling methodology, shown here for residential PV systems, considers a wide set of factors and many interactions between them. These bottom

Get Price

Distribution Grid Integration Unit Cost Database | Solar Market

Distribution Grid Integration Unit Cost Database NREL''s Distribution Grid Integration Unit Cost Database contains unit cost information for different components that may be used to integrate

Get Price

What Are the Components Affecting Inverter Prices?

What Are the Components Affecting Inverter Prices? Inverter prices can vary greatly depending on several key factors. Understanding these components can help you make an informed

Get Price

Solar Inverter Prices in 2025: Trends & Cost Breakdown

More efficient inverters tend to be slightly more expensive but provide better energy output. Additionally, the introduction of AI-driven smart

Get Price

Renewable energy Flashcards | Quizlet

High Maintaining ___ power factor minimizes the sizes and costs for conductors, over current protection, switchgear, and other equipment Static Inverters used in PV systems are

Get Price

As PV Market Evolved in the Last Year, Prices Went Up, Prices

Compared to last year''s report, modeled market prices for installed residential PV systems were 15% lower this year. Although balance of system costs were higher, those increased costs

Get Price

What are the typical costs associated with the balance

Generally, BoS components can account for approximately 10% to 50% of the total cost of a solar PV system, depending on the complexity and

Get Price

The basic principles that guide PV system costs | Aurora Solar

Hard costs cover expenses related to the physical equipment that goes into a solar PV system – including modules, inverters, balance of system (BoS) components, optional batteries, and

Get Price

Solar Photovoltaic System Cost Benchmarks

Market analysts routinely monitor and report the average cost of PV systems and components, but more detail is needed to understand the impact of recent and future technology

Get Price

How Much Does a Solar Inverter Cost?

The cost of these materials accounts for most of the cost of the whole inverter, especially the two core components of transistors and

Get Price

Solar Inverter Prices in 2025: Trends & Cost Breakdown

More efficient inverters tend to be slightly more expensive but provide better energy output. Additionally, the introduction of AI-driven smart inverters and IoT-based

Get Price

Configuration and Components of Photovoltaic Systems: A

Understanding the components of photovoltaic systems is crucial for optimizing their efficiency and reliability, making them a cornerstone of the global renewable energy

Get Price

What Is The Cost Breakdown Of A Solar Power System?

Discover the detailed cost breakdown of solar power systems in this comprehensive guide. Learn how expenses for panels, inverters, installation, and optional battery storage are allocated,

Get Price

Solar PV Inverter Cost Breakdown: Types and Prices

Solar PV inverters, while crucial, are not the primary cost component in solar PV systems. Typically, they represent about 6% to 9% of the total system cost. Other components

Get Price

Solar Inverter Cost Breakdown: Understanding

The raw materials and components required to manufacture solar power inverters are a significant portion of the operating costs for a business

Get Price

PV System Costs

Installation and Labor: The cost of professional installation, which can vary based on location, system complexity, and the installer''s rates. Capital costs are

Get Price

PV Inverter Products Manufacturing and Design

2.1 FIRST YEAR OVERVIEW In the first year of this subcontract, Xantrex developed the hardware for three advanced, high-impact PV inverter products for grid-tied applications. Two of the

Get Price

Solar Manufacturing Cost Analysis | Solar Market Research

These manufacturing cost analyses focus on specific PV and energy storage technologies—including crystalline silicon, cadmium telluride, copper indium gallium

Get Price

U.S. Solar Photovoltaic System and Energy Storage Cost

This report benchmarks installed costs for U.S. solar photovoltaic (PV) systems as of the first quarter of 2021 (Q1 2021). We use a bottom-up method, accounting for all system and project

Get Price

Solar Inverter Cost Analysis from Manufacturing

Conclusion The cost of manufacturing solar inverters is shaped by a variety of factors, from the cost of high-quality materials and production

Get Price

What are Solar Decommissioning Costs and How to Calculate

Uncover the secrets of solar decommissioning costs! Learn how to calculate them accurately & navigate the process with confidence. Eco-friendly future awaits!

Get Price

What are the typical costs associated with the balance of system

Generally, BoS components can account for approximately 10% to 50% of the total cost of a solar PV system, depending on the complexity and scale of the project.

Get Price

Solar Installed System Cost Analysis | Solar Market

NREL''s bottom-up cost modeling methodology, shown here for residential PV systems, considers a wide set of factors and many interactions

Get Price

The basic principles that guide PV system costs

Hard costs cover expenses related to the physical equipment that goes into a solar PV system – including modules, inverters, balance of system (BoS)

Get Price

Solar Inverter Cost Breakdown: Understanding Operating Expenses

The raw materials and components required to manufacture solar power inverters are a significant portion of the operating costs for a business in this industry.

Get Price

PV Cost and Component Data

The System Advisor Model (SAM) is a performance and financial model designed to estimate the cost of energy for grid-connected power projects.

Get Price

Solar Photovoltaic System Cost Benchmarks

Market analysts routinely monitor and report the average cost of PV systems and components, but more detail is needed to understand the impact of recent and

Get Price

6 FAQs about [PV inverter accounts for the component cost]

How much does a solar inverter cost?

The overall cost breakdown shows that while necessary, inverters are a relatively small part of the total investment in solar technology. After applying tax credits, the total cost to install a solar system, inverter included, comes to between $10,600 and $26,500. In 2023, there was a 15% drop in the price of residential systems.

How can a solar company reduce the cost of a PV system?

However, tools like Aurora Solar lead capture, solar sales, and PV design platforms can help your team drive down these soft costs – allowing you to service more customers using fewer resources. Figure 1. Cost breakdown of PV systems.

How many inverters does a PV system use?

The DC cables are connected to 19 utility-scale central inverters, each rated at 4 MW ac, giving the PV system a rated AC power output of 76 MW ac, which corresponds to an inverter loading ratio of 1.32. The inverters are made in Europe in a plant that produces 250 of them each year. These inverters are not subject to import tariffs.

How efficient are solar PV inverters?

Modern solar PV inverters, especially those utilizing materials like silicon carbide (SiC) and gallium nitride (GaN), are achieving efficiency levels above 99%, thereby reducing energy losses and enhancing the overall energy output.

How much will a PV system save?

Based on this simple analysis, the system will generate approximately $27,450 in savings over its lifetime. It is important to note that this is an approximation and does not take into account factors such as maintenance costs or degradation over time. However, as grid electricity prices increase, the value of the PV system increases as well.

What are the different types of solar PV costs?

There are two general categories of expenses – capital costs and operations & management (O&M) costs. Capital costs refer to the fixed, one-time expenses associated with designing and installing solar PV systems. These can further be categorized into hard costs and soft costs:

More related information

-

Solar PV Water Pump Inverter Cost in Pakistan

Solar PV Water Pump Inverter Cost in Pakistan

-

Project cost of PV inverter

Project cost of PV inverter

-

Türkiye PV dedicated off-grid inverter

Türkiye PV dedicated off-grid inverter

-

Huawei Slovenia PV Inverter Market

Huawei Slovenia PV Inverter Market

-

PV panel power and inverter configuration

PV panel power and inverter configuration

-

70 PV inverter price

70 PV inverter price

-

Italian photovoltaic solar water pump inverter cost

Italian photovoltaic solar water pump inverter cost

-

Price of PV Energy Storage Inverter in Jordan

Price of PV Energy Storage Inverter in Jordan

Commercial & Industrial Solar Storage Market Growth

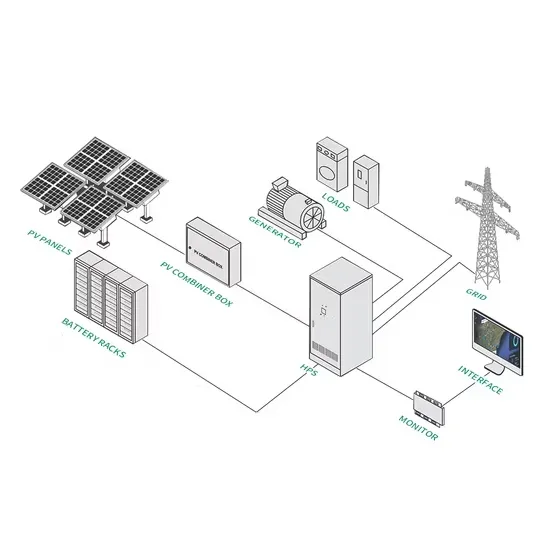

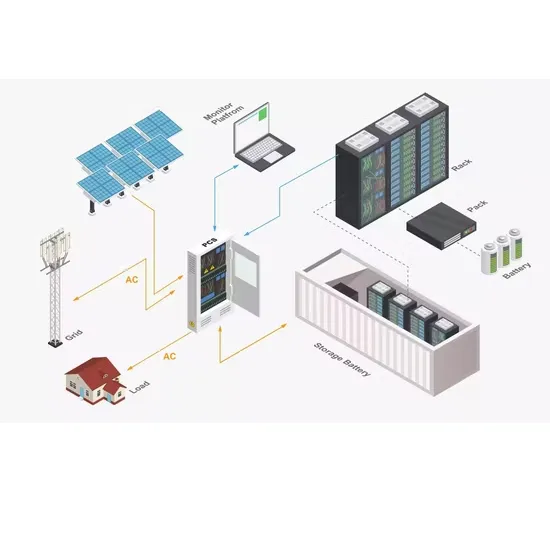

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.