液冷散热技术在电化学储能系统中的研究进展

Research progress in liquid cooling and heat dissipation technologies for electrochemical energy storage systems [J]. Energy Storage Science and Technology, 2024, 13 (10): 3596-3612.

Get Price

THERMAL MANAGEMENT FOR ENERGY STORAGE:

To maintain the temperature within the container at the normal operating temperature of the battery, current energy storage containers have two main heat dissipation

Get Price

Heat Dissipation Superstars: How Next-Gen Lithium Battery

Picture this: a lithium battery pack working overtime in a solar farm storage container. Without proper heat dissipation type energy storage lithium battery pack technology, it''s like watching

Get Price

What does energy storage and heat dissipation mean?

There are various energy storage systems, including mechanical storage such as pumped hydro and flywheels, electrical storage technologies

Get Price

EXPLORING THE ADVANTAGES OF AIR-COOLED

Higher Energy Density: Liquid-cooled systems enable higher energy density, as they can dissipate heat more efficiently. This allows for the

Get Price

Several Recommended Heat Dissipation Systems for

Several heat dissipation systems used in the energy storage market especially for battery container temperature control, that are integrated

Get Price

THERMAL MANAGEMENT FOR ENERGY

To maintain the temperature within the container at the normal operating temperature of the battery, current energy storage containers have

Get Price

Research and application of containerized energy

Containerized energy storage systems currently mainly include several cooling methods such as natural cooling, forced air cooling, liquid

Get Price

Research and application of containerized energy storage thermal

Containerized energy storage systems currently mainly include several cooling methods such as natural cooling, forced air cooling, liquid cooling and phase change cooling. Natural cooling

Get Price

What does energy storage and heat dissipation mean?

There are various energy storage systems, including mechanical storage such as pumped hydro and flywheels, electrical storage technologies like batteries and

Get Price

What Is a Container Energy Storage System?

A deep dive into containerized BESS. Explore key components, grid-scale applications, safety, and how they support renewable energy. Read our expert guide.

Get Price

Heat dissipation principle of energy storage power station container

Does airflow organization affect heat dissipation behavior of container energy storage system? In this paper, the heat dissipation behavior of the thermal management system of the container

Get Price

Container energy storage system heat dissipation and refrigeration

About Container energy storage system heat dissipation and refrigeration As the photovoltaic (PV) industry continues to evolve, advancements in Container energy storage system heat

Get Price

Simulation analysis and optimization of containerized energy storage

This approach not only improves heat dissipation efficiency and reduces experimental costs but also informs the design of containerized energy storage battery cooling

Get Price

Liquid Cooling in Energy Storage: Innovative Power Solutions

Embracing a Sustainable Future The integration of liquid cooling technology in energy storage solutions represents a significant step towards a sustainable future. By

Get Price

Thermal conductive interface materials and heat dissipation of energy

This article will introduce you the mainstream heat dissipation methods and thermal conductive interface materials of energy storage modules, including the classifications

Get Price

Introduction on Heat Dissipation Technology of Energy Storage

Background Battery thermal dissipation technology, also called cooling technology, is essentially a heat exchange process that reduces the internal temperature of the battery by

Get Price

Shipping Container Energy Storage System Guide

As the demand for eco-friendly and flexible energy solutions grows, the concept of containerized energy storage has come to the forefront. These systems leverage the

Get Price

What is Container Energy Storage? Applications & Advantages

Container energy storage systems, with their modularity, mobility and high efficiency, have gradually emerged in the field of energy storage. This article will introduce the

Get Price

energy storage container

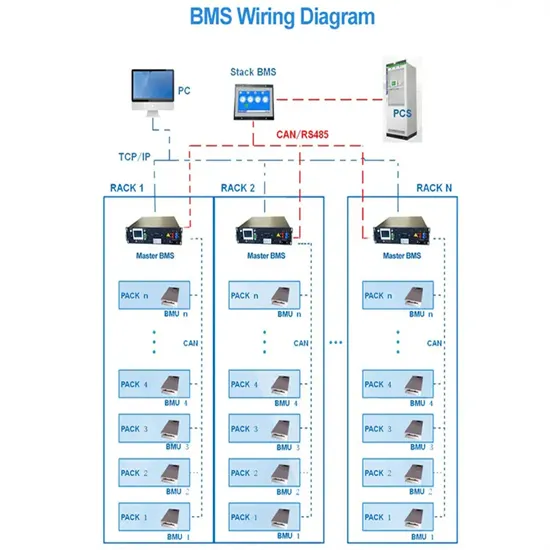

Container Energy Storage System (CESS) is an integrated energy storage system developed for the mobile energy storage market. It integrates battery cabinets, lithium battery management

Get Price

Combined Heat and Power Technology Fact Sheet Series:

Thermal energy storage (TES) technologies heat or cool a storage medium and, when needed, deliver the stored thermal energy to meet heating or cooling needs.

Get Price

energy storage container

Container Energy Storage System (CESS) is an integrated energy storage system developed for the mobile energy storage market. It integrates battery

Get Price

Research on air‐cooled thermal management of energy storage

Abstract Battery energy storage system occupies most of the energy storage market due to its superior overall performance and engineering maturity, but its stability and

Get Price

Thermal conductive interface materials and heat

This article will introduce you the mainstream heat dissipation methods and thermal conductive interface materials of energy storage

Get Price

Liquid Cooling for Energy Storage——Selection of

The isothermal liquid cooling plate for energy storage batteries is a heat dissipation technology applied to energy storage batteries. It can effectively

Get Price

Integrated cooling system with multiple operating modes for

Therefore, the integration of vapor compression refrigeration technology, vapor pump heat pipe technology and heat pump technology for temperature control of energy

Get Price

CN110707391A

The invention provides a self-rotating heat conduction and dissipation method of a container energy storage battery, which comprises the following steps: the container, and set up energy

Get Price

6 FAQs about [What are the container energy storage and heat dissipation technologies ]

What is a container energy storage system?

Containerized energy storage systems play an important role in the transmission, distribution and utilization of energy such as thermal, wind and solar power [3, 4]. Lithium batteries are widely used in container energy storage systems because of their high energy density, long service life and large output power [5, 6].

What is a composite cooling system for energy storage containers?

Fig. 1 (a) shows the schematic diagram of the proposed composite cooling system for energy storage containers. The liquid cooling system conveys the low temperature coolant to the cold plate of the battery through the water pump to absorb the heat of the energy storage battery during the charging/discharging process.

What is container energy storage temperature control system?

The proposed container energy storage temperature control system integrates the vapor compression refrigeration cycle, the vapor pump heat pipe cycle and the low condensing temperature heat pump cycle, adopts variable frequency, variable volume and variable pressure ratio compressor, and the system is simple and reliable in mode switching.

What is thermal energy storage?

Thermal energy storage (TES) technologies heat or cool a storage medium and, when needed, deliver the stored thermal energy to meet heating or cooling needs.

What is container energy storage system (cess)?

Container Energy Storage System (CESS) is an integrated energy storage system developed for the mobile energy storage market. It integrates battery cabinets, lithium battery management system (BMS), container dynamic loop monitoring system, and energy storage converters and energy management systems according to customer requirements.

How much power does a containerized energy storage system use?

In Shanghai, the ACCOP of conventional air conditioning is 3.7 and the average hourly power consumption in charge/discharge mode is 16.2 kW, while the ACCOP of the proposed containerized energy storage temperature control system is 4.1 and the average hourly power consumption in charge/discharge mode is 14.6 kW.

More related information

-

What are the heat dissipation devices for high-voltage energy storage

What are the heat dissipation devices for high-voltage energy storage

-

What is the principle of liquid-cooled energy storage container

What is the principle of liquid-cooled energy storage container

-

What is the ranking of energy storage container manufacturers

What is the ranking of energy storage container manufacturers

-

What is the thickness of the photovoltaic energy storage container

What is the thickness of the photovoltaic energy storage container

-

What is the price of the Dominican container energy storage station

What is the price of the Dominican container energy storage station

-

What is the price of Moldova energy storage container

What is the price of Moldova energy storage container

-

What is the price of the Bahamas energy storage cabinet container

What is the price of the Bahamas energy storage cabinet container

-

What are the overseas energy storage container companies

What are the overseas energy storage container companies

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.