Thermal conductive interface materials and heat dissipation of energy

This article will introduce you the mainstream heat dissipation methods and thermal conductive interface materials of energy storage modules, including the classifications

Get Price

Ultra-thin vapour chamber based heat dissipation technology for

Today, liquid cooling is an effective heat dissipation method that can be classified into direct cooling [7] and cold plate-based indirect cooling (CPIC) methods [8] according to

Get Price

Changes in heat dissipation requirements of energy storage

With the update and upgrade of energy storage systems, the heat dissipation requirements of energy storage converters have also changed, and corresponding heat

Get Price

Basics of Thermal Resistance and Heat Dissipation

Basics of Thermal Resistance and Heat Dissipation Challenges in designing electronic equipment include downsizing, improvement in efficiency, support for electromagnetic compatibility

Get Price

Research and application of containerized energy

Containerized energy storage systems currently mainly include several cooling methods such as natural cooling, forced air cooling, liquid cooling and phase

Get Price

BATTERY ENERGY STORAGE SYSTEMS (BESS)

We also provide customized connection solutions for charging stations, high-voltage control cabinets, and energy-storage and communication power supplies. At TE, we are dedicated to

Get Price

How do energy storage products dissipate heat? | NenPower

Thermal insulators prevent excessive heat from escaping core components of energy storage products where heat retention is vital for efficiency. These materials can be

Get Price

The role of the heat dissipation network for energy storage

By deploying multi-type energy storage systems, such as electrochemical energy storage, heat storage, and gas storage, the consumption of clean energy can be realized at a large scale

Get Price

Thermal Management Strategies in High-Power

This paper explores various thermal management techniques, including active and passive cooling systems, phase change materials, and

Get Price

Advancing heat exchangers for energy storage: A comprehensive

The growing demand for energy and the necessity to enhance the efficiency of heat exchangers have triggered numerous studies aimed at improving convective heat transfer

Get Price

How does the high voltage switch store energy? | NenPower

Yes, high voltage energy storage systems can be adapted for residential use, particularly as homeowners increasingly seek ways to incorporate renewable energy solutions.

Get Price

Heat management technology for solid‐state high voltage and high

This review may guide selecting an appropriate cooling technique and conducting a heat management design for high voltage high repetition pulse generators in numerous

Get Price

[PDF] Design and optimization of heat dissipation for a high

Building upon this foundation, the article conducts a thorough analysis of how the position and shape of the box''s openings impact the device''s temperature rise. The findings suggest that

Get Price

[PDF] Design and optimization of heat dissipation for a high-voltage

Building upon this foundation, the article conducts a thorough analysis of how the position and shape of the box''s openings impact the device''s temperature rise. The findings suggest that

Get Price

What is the heat dissipation of energy storage power supply?

As the demand for energy storage solutions escalates, innovative technologies are emerging to enhance heat dissipation strategies. Research into phase change materials,

Get Price

Low vs High Voltage Home Energy Storage Systems: Pros, Cons

Efficiency, Safety, and Maintenance 4.1 Energy Efficiency High-voltage batteries minimize transmission loss and convert DC to AC more efficiently. Low-voltage systems tend

Get Price

Ultrahigh capacitive energy storage through dendritic

We propose a microstructural strategy with dendritic nanopolar (DNP) regions self-assembled into an insulator, which simultaneously

Get Price

High-Voltage Energy Storage

A high-voltage energy storage system (ESS) offers a short-term alternative to grid power, enabling consumers to avoid expensive peak power charges or supplement inadequate grid

Get Price

Dielectric Loss: Definition, Causes and Factors

Dielectric loss refers to the conversion of part of the electrical energy into heat when a dielectric material is exposed to an alternating electric

Get Price

Design and Optimization of Heat Dissipation for a High-Voltage

This research offers invaluable practical insights and novel perspectives on the optimization of thermal management designs for box-type electronic devices, significantly

Get Price

The most comprehensive guide to thermal energy

Thermal energy storage technology (TES) temporarily stores energy (solar heat, geothermal, industrial waste heat, low-grade waste heat,

Get Price

Thermal Management Strategies in High-Power Energy Storage Device

This paper explores various thermal management techniques, including active and passive cooling systems, phase change materials, and advanced heat sink designs,

Get Price

A high heat dissipation strategy based on a multi-scale porous

Heat dissipation is critical for energy efficiency; high operating temperatures can even cause electronic device failure. Herein, a high heat dissipation strategy is proposed and

Get Price

Thermal conductive interface materials and heat

This article will introduce you the mainstream heat dissipation methods and thermal conductive interface materials of energy storage

Get Price

Energy Dissipation Systems for Seismic Applications

Abstract: This paper presents a summary of current practice and recent developments in the application of passive energy dissipation systems for seismic protection of structures. The

Get Price

6 FAQs about [What are the heat dissipation devices for high-voltage energy storage ]

How to improve heat dissipation of transient high voltage electronic equipment?

The heat dissipation of transient high voltage electronic equipment is analyzed. The more reliable natural heat dissipation method is adopted. Enhance heat dissipation by strengthening the heat conduction and sensible heat storage. Iron rod and ceramic are used to enhance heat conduction and heat storage.

Does sensible heat storage enhance heat dissipation characteristics of electronic devices?

Few researchers, however, have studied the enhancement effect of sensible heat storage on the heat dissipation characteristics of electronic devices. In this research, the issue of an efficient transient heat dissipation method for the aluminum-shelled high-power resistor is raised.

How does heat storage improve transient heat dissipation?

Internal heat conduction and sensible heat storage continue to be the primary method of enhancing transient heat dissipation. To better evaluate the heat storage performance of the resistor, the concept of heat storage efficiency is put forward.

What happens if a high power resistor is used in latent heat storage?

Since high power resistors work in more severe enviornment than other high-power electronic devices, if the latent heat storage method is used, it is likely to experience a solid–liquid-gas phase transition because of the device’s high temperature. It may cause the internal air pressure to be too high.

What is active heat dissipation?

Active heat dissipation mainly includes forced air-cooling heat dissipation, forced liquid cooling and other methods. The following section will intuitively classify the heat management technologies based on the heat transfer method and cooling agent utilised by each technology.

Which cooling method is suitable for hvprgs with moderate heat dissipation flux?

Air cooling, as the most widely used cooling technique, is suitable for HVPRGs with moderate heat dissipation flux. And it is applicable to both the component cooling and the overall system cooling. The air medium has no problem with the high voltage insulation, leakage pollution, and maintenance.

More related information

-

What are the container energy storage and heat dissipation technologies

What are the container energy storage and heat dissipation technologies

-

Heat dissipation of energy storage devices

Heat dissipation of energy storage devices

-

What are the energy storage devices in Tanzania

What are the energy storage devices in Tanzania

-

Energy storage equipment heat dissipation

Energy storage equipment heat dissipation

-

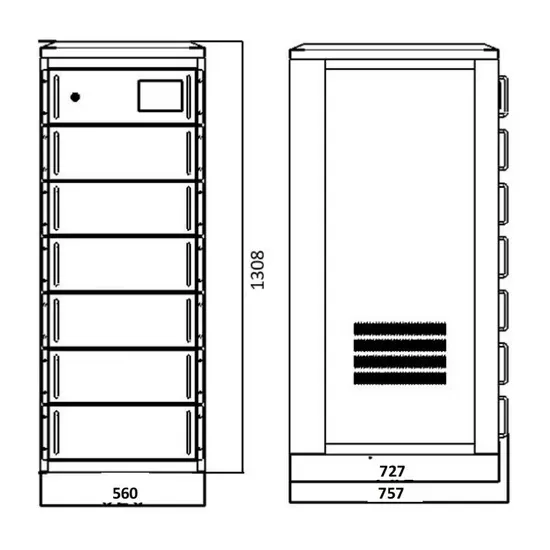

Energy storage battery cabinet heat dissipation

Energy storage battery cabinet heat dissipation

-

Current status of heat dissipation in communication base station energy storage systems

Current status of heat dissipation in communication base station energy storage systems

-

Liquid-cooled energy storage battery cabinet heat dissipation

Liquid-cooled energy storage battery cabinet heat dissipation

-

Heat dissipation type energy storage lithium battery station cabinet

Heat dissipation type energy storage lithium battery station cabinet

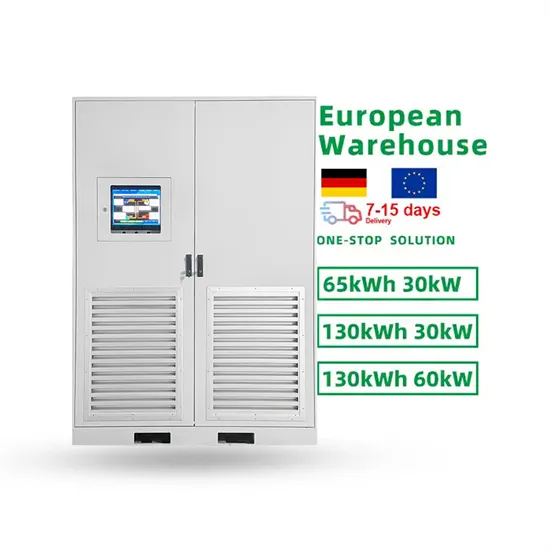

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.