Inverter Based Resource Performance Issues

Greater than 2/3 of voltage and frequency protections settings reported are not set based on inverter capability. The use of phase lock loop (PLL) loss of synchronism protection was

Get Price

Inverters: The secret to minimizing power loss and maximizing

Explore essential strategies to minimize power loss in inverters, focusing on switching dynamics, resistive losses, and SiC semiconductor advantages, while optimizing

Get Price

Understanding Solar Inverter Losses Efficiently

The conversion process itself can contribute to power loss in the inverter. During the conversion of DC power to AC power, circuit resistance

Get Price

Photovoltaic Inverter Reliability Assessment

With the input PV power obtained from the irradiance and temperature data, the average inverter loss model can be used to measure the junction and heat sink temperatures of the DC-DC

Get Price

Big inverters vs smaller inverters

The dominate idle consumption on inverters should be caused by the power consumed switching the high frequency power MOSFET gate input capacitance. The larger

Get Price

How to Analyze and Calculate True Efficiency in Inverters

Learn how to calculate true inverter efficiency, analyze performance factors, and discover SOROTEC''s high-efficiency solutions for optimal energy conversion.

Get Price

Inverter Efficiency: Complete Guide and Calculator

Inverter efficiency is how much Direct Current (DC) is converted into Alternating Current (AC). This is the primary function of an inverter, unfortunately, it is not 100% efficient. It means that

Get Price

Inverter Efficiency: Understanding Conversion Rates

With the rising demand for dependable power solutions, inverter manufacturers across India are playing a crucial role in supplying high-quality

Get Price

How Long Can I Run The Power Inverter On My Battery?

How long does an inverter that uses battery power actually last? This article will delve into this question and provide knowledge and calculations.

Get Price

Loss Minimization in Inverters calculation for Electrical Engineering

The higher the efficiency, the less power is lost in the inverter. There are a number of factors that can affect the efficiency of an inverter, including the input voltage, output

Get Price

Inverter Efficiency: Complete Guide and Calculator

Inverter efficiency is how much Direct Current (DC) is converted into Alternating Current (AC). This is the primary function of an inverter, unfortunately, it is not

Get Price

Understanding DC/AC Ratio – HelioScope

A common source of confusion in designing solar systems is the relationship between the PV modules, inverter (s), and their "nameplate" power ratings.

Get Price

Motor Drive Efficiency and Loss at High Frequencies

Studying high switching frequency in motor drive systems offers valuable insights into efficiency and loss characteristics. This article, based on

Get Price

Is there a formula to figure out power loss of a power inverter?

Is there a formula that will give me a ball park idea of how much power I will lose when I run my DC battery bank through a power inverter? Is this something that varies

Get Price

Big inverters vs smaller inverters

The dominate idle consumption on inverters should be caused by the power consumed switching the high frequency power MOSFET gate input

Get Price

How Solar Inverter and MPPT Controller Choices Affect Power

3. Less circuit loss: The MPPT power circuit has an inductor and a switch tube, which will cause losses during operation. The more MPPT circuits, the greater the loss. Generally speaking, the

Get Price

Inverter Model: Input and Output

-If the MPP power is greater than the acceptable input power (PnomDC), the inverter will clip the operating point to the input power which corresponds to Pnom (AC).

Get Price

Should you oversize your solar array / oversize your

After numerous questions about the relationship between solar panel power and inverter power, I decided to put together this blog post. Now

Get Price

How to Reduce DC to AC Inverter Losses & Boost Efficiency?

Understanding inverter power loss, selecting efficient inverters and adopting appropriate energy saving measures to improve the efficiency of home energy use.

Get Price

6.5. Efficiency of Inverters | EME 812: Utility Solar

Some of the power can be lost as heat, and also some stand-by power is consumed for keeping the inverter in powered mode. The general efficiency

Get Price

How to Analyze and Calculate True Efficiency in

Learn how to calculate true inverter efficiency, analyze performance factors, and discover SOROTEC''s high-efficiency solutions for optimal energy conversion.

Get Price

Inverter Efficiency: Understanding How Much Power You''re

In simple terms, inverter efficiency refers to how well an inverter converts DC electricity into usable AC power. No inverter is 100% efficient—some energy always gets lost

Get Price

Impact of inverter loading ratio on solar photovoltaic system

We use the term inverter loading ratio (ILR) to describe this ratio of the array''s nameplate DC power rating to the inverter''s peak AC output rating. Other commonly-used

Get Price

Efficiency of Inverter: Calculation & Equation Guide

How Much Is the Loss of Power In an Inverter? The efficiency of the inverter is defined as the ratio of output power to input power, which is given as a percentage.

Get Price

6.5. Efficiency of Inverters | EME 812: Utility Solar Power and

Some of the power can be lost as heat, and also some stand-by power is consumed for keeping the inverter in powered mode. The general efficiency formula is: where P AC is AC power

Get Price

Inverter clipping: How to maximize solar project value

Balancing inverter clipping ratios to tune cash flows Pushing the limits of DC loading on an inverter could be detrimental to its long-term service

Get Price

How to Reduce DC to AC Inverter Losses & Boost

Understanding inverter power loss, selecting efficient inverters and adopting appropriate energy saving measures to improve the efficiency of

Get Price

6 FAQs about [The greater the inverter power the greater the loss]

What is the efficiency of an inverter?

Efficiency of Inverters The efficiency of an inverter indicates how much DC power is converted to AC power. Some of the power can be lost as heat, and also some stand-by power is consumed for keeping the inverter in powered mode.

What if inverter load is less than 15%?

In general, if the inverter is loaded less than 15%, the efficiency will be low. As a result, a good match between inverter capacity and load capacity will allow us to obtain more efficiency, which is more ac output power from the inverter for the same DC input power. Efficiency of Inverter per Output Power (Reference: inverter.com)

Why do inverters lose energy?

There are 2 real reasons that you lose energy in an inverter: Heat loss – During the conversion of DC to AC some of the energy is lost as heat. Internal systems – Inverters need a little power for run systems like cooling, safety protections, LEDs, and digital screens.

Why is my inverter efficiency lower during hours?

Inverter efficiency will be lower during hours when the array output power is low, such as owing to shading or extremely early/late in the day, than during hours when the array is running under full irradiance with no shading. This is normal behavior, but because the input power is minimal, it usually has no impact on the system’s performance.

How much power is lost in an inverter?

Suppose the efficiency of the inverter is 90 percent, then 10 percent of the power is lost in the inverter. It depends on the load as to how efficient the inverter will be. Generally speaking, it is usually at its peak at about two-thirds of the capacity of the inverter.

Is an inverter 100% efficient?

No inverter is 100% efficient—some energy always gets lost as heat during the conversion. Most modern inverters have efficiency ratings between 90% and 98%. Let’s break it down: If you feed 1000 watts of DC power into your inverter and it outputs 950 watts of AC power, your inverter efficiency is 95%.

More related information

Commercial & Industrial Solar Storage Market Growth

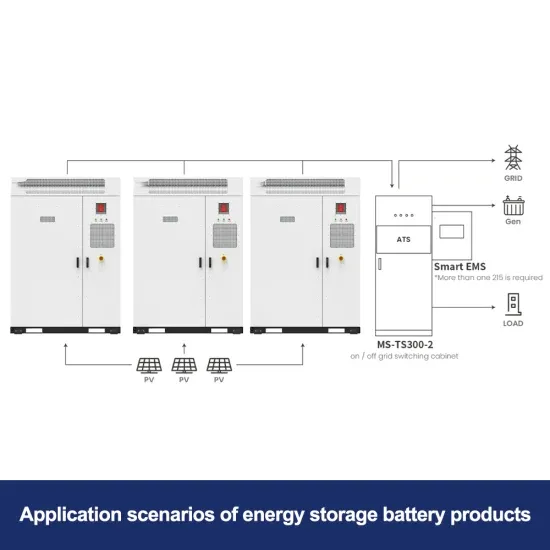

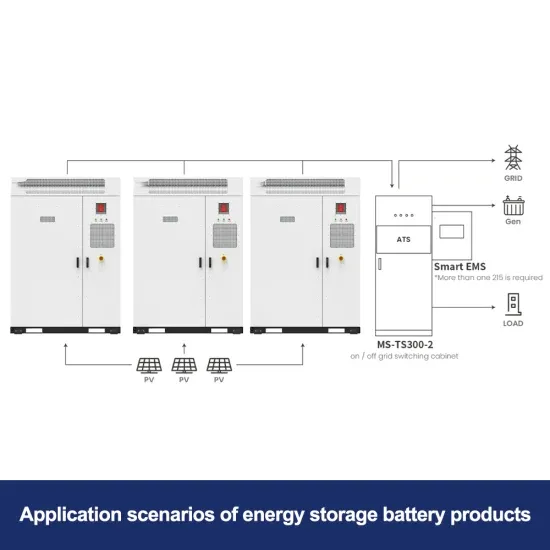

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.

Which inverter has greater power

Which inverter has greater power

The real-time power of the inverter is greater than the rated power

The real-time power of the inverter is greater than the rated power

PV inverter power loss

PV inverter power loss

Large inverter with high power

Large inverter with high power

We photovoltaic panel power loss

We photovoltaic panel power loss

Inverter power cost

Inverter power cost

Italian 60v power inverter

Italian 60v power inverter