EU Solar Manufacturing Map

The EU Solar Manufacturing map gives an overview of solar manufacturing companies active along the solar PV chain. On this map, you''ll find manufacturers spanning from polysilicon to

Get Price

MANUFACTURING OF SOLAR PANELS: FROM CELL TO

Here we have emphasized on complete panel manufacturing process viz. Manufacturing of PV Cell, different types of PV Cell, Solar Panels, Testing of Solar Panels, Packaging & Quality

Get Price

Temperature Dependent Photovoltaic (PV) Efficiency and Its Effect on PV

PV modules with less sensitivity to temperature are preferable for the high temperature regions and more responsive to temperature will be more effective in the low

Get Price

Solar Panel Manufacturing: A Step-by-Step Overview

In this guide, we will cover the basics of solar panel manufacturing — including the various components of a solar module, the photovoltaics manufacturing process, the

Get Price

What is the Manufacturing Process of Solar Panels?

Here''s a detailed breakdown of each step in the production process: 1. Silicon Processing. The journey of solar panel manufacturing begins with silicon processing. Silicon,

Get Price

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get Price

Journal of Cleaner Production

Recycling PV panels through e-waste management is crucial step in minimizing the environmental impact of end-of-life PV systems such as the release of heavy metals into the

Get Price

How to Start a Solar Panel Manufacturing Plant: Complete Guide

To put it simply, a solar panel manufacturing plant is a facility where photovoltaic cells are produced and assembled into solar panels. These panels convert sunlight into usable

Get Price

PV Solar Cell Manufacturing Process & Equipment Explained

Solar photovoltaic lamination stands as an important step in the solar module manufacturing process. This technique involves encasing solar cells in protective materials, typically EVA and

Get Price

What is the Manufacturing Process of Solar Panels?

Here''s a detailed breakdown of each step in the production process: 1. Silicon Processing. The journey of solar panel manufacturing

Get Price

How are solar panels manufactured? | Solar

We''ll look at the manufacturing process for most common panels, photovoltaic or PV. Photovoltaic cells make electricity from sunlight. Basically, they do this by enabling light

Get Price

IEA: Global photovoltaic module production capacity will exceed

According to the International Energy Agency (IEA), global solar panel production capacity will exceed 1.5TW by 2035. Its latest report, Energy Technology Outlook 2024,

Get Price

Processes for the assembly and production of solar panels

In short, a number of specialists and 20-25 machines closely work together from cell to module. The process revolves around ten major steps, which divide into several sub-steps, to produce

Get Price

Global Solar Pv Manufacturing Trends By Country And Region

Explore solar PV manufacturing trends and future projections by country and region from 2021-2027 with detailed charts and statistics.

Get Price

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes

Get Price

The State of the Solar Industry

State-by-State Electricity from Solar (2023) Sources: U.S. Energy Information Administration, "Electric Power Monthly," forms EIA-023, EIA-826, and EIA-861. U.S. Energy Information

Get Price

Life Cycle Greenhouse Gas Emissions from Solar Photovoltaics

LCA of Energy Systems LCA can help determine environmental burdens from "cradle to grave" and facilitate comparisons of energy technologies. Comparing life cycle stages and proportions

Get Price

How Does Solar Work?

Learn solar energy technology basics: solar radiation, photovoltaics (PV), concentrating solar-thermal power (CSP), grid integration, and soft costs.

Get Price

How to Start a Solar Panel Manufacturing Plant:

To put it simply, a solar panel manufacturing plant is a facility where photovoltaic cells are produced and assembled into solar panels. These panels convert

Get Price

PV Solar Cell Manufacturing Process & Equipment

Solar photovoltaic lamination stands as an important step in the solar module manufacturing process. This technique involves encasing solar cells in

Get Price

Solar Cell Production: from silicon wafer to cell

Producers of solar cells from silicon wafers, which basically refers to the limited quantity of solar PV module manufacturers with their own wafer

Get Price

Solar Panel Production Process: A Complete Guide

This document gives guidelines on the solar panel production process. It also gives details of the relevant raw materials that are needed by solar panel

Get Price

How Are Solar Cells Made? A Complete Guide To

Solar panels or PV modules are made by assembling solar cells into a frame that protects them from the environment. A typical PV module

Get Price

Top 10 Solar Panel Manufacturers in India in 2025 [Updated List]

In this blog, we have listed top solar manufacturers in India. We have concluded this list from the top manufacturers and fetched the best among them.

Get Price

Solar Panel Manufacturing: A Step-by-Step Overview

In this guide, we will cover the basics of solar panel manufacturing — including the various components of a solar module, the photovoltaics

Get Price

Solar panel manufacturing process: from cell to module

Solar panel manufacturing process After having produced the solar cells and placed the electrical contacts between the cells, they are then wired and subsequently arrayed.

Get Price

More related information

-

Honduras standard photovoltaic module solar panels

Honduras standard photovoltaic module solar panels

-

Photovoltaic power generation production of monocrystalline silicon panels

Photovoltaic power generation production of monocrystalline silicon panels

-

Photovoltaic cell module production project

Photovoltaic cell module production project

-

Standard photovoltaic module solar panels

Standard photovoltaic module solar panels

-

Production of photovoltaic panels

Production of photovoltaic panels

-

Solar photovoltaic module production in South Korea

Solar photovoltaic module production in South Korea

-

Can photovoltaic panels be installed on high-rise roofs

Can photovoltaic panels be installed on high-rise roofs

-

Polish double-glass photovoltaic module manufacturer

Polish double-glass photovoltaic module manufacturer

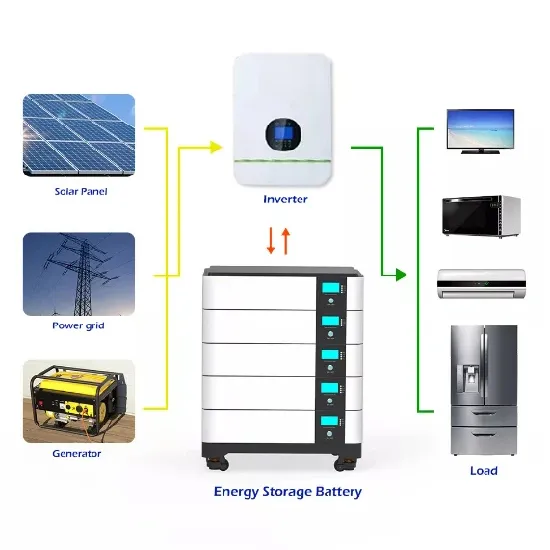

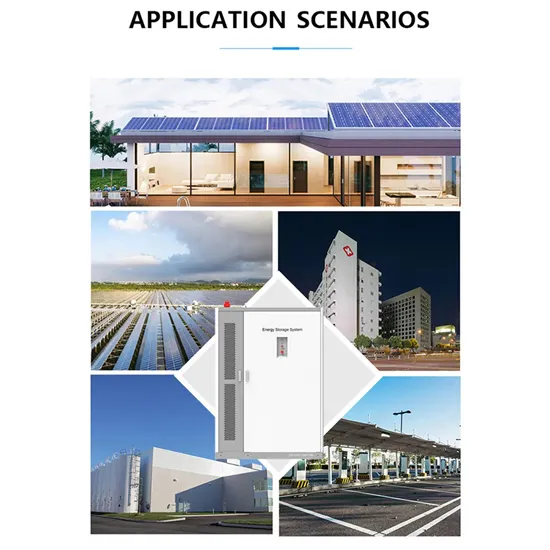

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

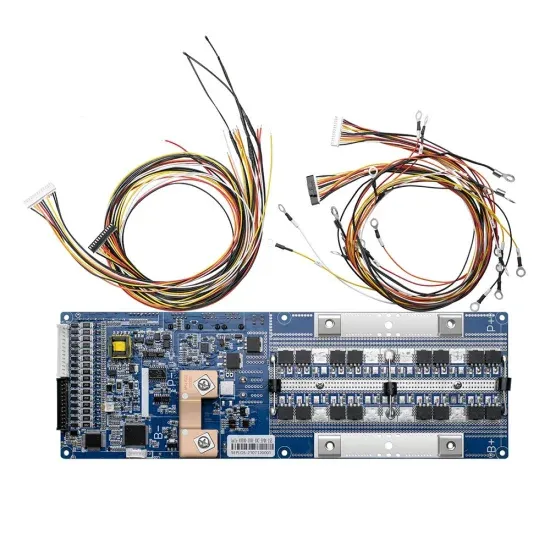

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.