Lithium-Ion Battery Pack Manufacturing Process Guide

From precise cell welding to smart BMS integration—uncover how lithium-ion battery packs are engineered for safety and power.

Get Price

[Step Guide ] How to Solder Multiple Lithium Batteries?

Learn step-by-step how to solder lithium batteries in series or parallel safely and effectively with this detailed, hands-on guide.

Get Price

Complete Guide to Lithium Battery Pack Design and Assembly

A lithium battery pack is not just a simple assembly of batteries. It is a highly integrated and precise system project. It covers multiple steps, including cell selection,

Get Price

Lithium Battery Pack Assembly: A Comprehensive Guide

Join us as we delve into the intricate art of lithium battery pack assembly, unveiling the expertise and precision engineering required to bring these cutting-edge technologies to life.

Get Price

Lithium Battery Pack Assembly: A Comprehensive Guide

Join us as we delve into the intricate art of lithium battery pack assembly, unveiling the expertise and precision engineering required to bring

Get Price

Design approaches for Li-ion battery packs: A review

Assessment of the forced air-cooling performance for cylindrical lithium-ion battery packs: a comparative analysis between aligned and staggered cell arrangements

Get Price

Advanced Lithium Battery Manufacturing Capabilities

We design and assemble prismatic battery packs using fully automated systems. Our cleanroom-compatible environment ensures consistent builds for high-energy-density applications,

Get Price

New Assembly Line to Make Lithium-Metal Batteries for EVs

TUCSON, AZ—Sion Power, a manufacturer of lithium-metal batteries for electric vehicles and energy storage, has installed a new large-format battery cell production line at its

Get Price

How to Build a Lithium Ion Battery Pack? A Step by Step Guide

Preparing all the materials and tools needed in how to build a lithium ion battery pack before starting the assembly process is a fundamental thing to do. Proper assembly will

Get Price

Mastering the Art of Lithium Battery Pack Assembly: A

Mastering the Art of Lithium Battery Pack Assembly. Join me on an adventure into the fascinating world of lithium battery pack assembly. As we

Get Price

BUILD A LARGE LITHIUM BATTERY PACK

Only $2 for 5 pcs PCBs and Free SMT Assembly at JLCPCB& Get $54 for New Users: https://jlcpcb /cyt In this video I will show how we can build our lithium battery pack for an old ups. It...

Get Price

Battery Cell Manufacturing Process

Battery Cell Manufacturing Process In order to engineer a battery pack it is important to understand the fundamental building blocks, including the battery

Get Price

BU-305: Building a Lithium-ion Pack

Use only lithium-ion batteries with a designated protection circuit and approved charger. Discontinue using a battery and/or charger if the pack temperature rises more than 10ºC (18ºF)

Get Price

Battery Pack Designer''s Guide: From Beginner to Pro [With

Battery pack design requires understanding both fundamental electrochemistry and application-specific engineering requirements. Custom battery pack applications have expanded

Get Price

Mastering the Art of Lithium Battery Pack Assembly: A

Mastering the Art of Lithium Battery Pack Assembly. Join me on an adventure into the fascinating world of lithium battery pack assembly. As we explore the intricate craft of

Get Price

How to Build a Lithium Ion Battery Pack? A Step by

Lithium-ion (Li-ion) batteries have become a primary power source for a various applications, from consumer electronics, electric vehicles, power

Get Price

How to Assemble a Battery Pack in 8 Easy Steps? [2025 Guide]

In this step-by-step guide, I''ll walk you through the entire DIY battery pack assembly process to help you build a safe, high-performance battery.

Get Price

Cell Contact System Assembly for Lithium-Ion

This article reveals the whole CCS assembly process for the lithium battery pack, from flexible PCB fabrication, and flexible PCB assembly,

Get Price

Custom Lithium Ion Battery Packs vs Off-the-Shelf: What

Development timelines represent a critical design parameter when selecting between . custom lithium ion battery packs and off-the-shelf solutions. Standard battery packs

Get Price

Lithium ion Battery Pack Assembly Line

Smooth assembly process, high production efficiency and yield rate, suitable for large and medium-sized square aluminum shell battery PACK assembly needs.

Get Price

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

Building lithium-ion battery packs requires systematic engineering across multiple disciplines, from cell selection to safety compliance. Here are the essential insights every

Get Price

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

Assembling a lithium battery pack is a critical skill for anyone working with modern energy storage systems. Whether you''re powering an electric vehicle, a renewable energy

Get Price

Design Custom Battery Pack for Complex Shapes

The durability and reliability of each battery pack design is confirmed through extensive vibration testing, thermal cycling assessments, and safety certifications. Large

Get Price

BUILD A LARGE LITHIUM BATTERY PACK

Only $2 for 5 pcs PCBs and Free SMT Assembly at JLCPCB& Get $54 for New Users: https://jlcpcb /cyt In this video I will show how we can build our lithium battery pack

Get Price

Lithium-Ion Battery Pack Manufacturing Process Guide

Conclusion The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each

Get Price

Lithium Battery Pack Assembly: A Comprehensive Guide

Quality control is a cornerstone of the lithium battery pack assembly process. At every stage, inline testing and inspection stations

Get Price

Sturcture of Battery: From Cell to Module and Pack | How are

The Structure of a Battery To review a battery''s structure from a macro-view as a whole pack until the smallest units, which are referred to as battery cells, batteries are by no

Get Price

6 FAQs about [Large-cell lithium battery pack assembly]

What is a lithium-ion battery pack?

The Lithium-Ion battery packs at La-Z-Boy have multiple functionalities. Here are some of them in a nutshell Works with all La-Z-Boy power recliners, sofas, and sectionals (excluding lift chairs). Red flashing light while charging, green steady light when fully charged (approx. 5-7 hours charge time).

What do we have for lithium-ion battery pack assembly?

For lithium-ion battery pack assembly, we offer complete solutions. This includes different sizes of barley paper, battery cells, plastic holders, nickel strip, handheld spot welder, PVC, and high-temperature resistant adhesive tape. We also provide rolls of various widths and cut the length as per customer requirements.

What is a high-performance lithium battery pack?

As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the heart of this burgeoning industry lies a meticulously orchestrated assembly process, where individual lithium-ion cells are transformed into powerful energy storage systems.

What is a lithium battery management system (BMS)?

The cells within a lithium battery pack are typically arranged in series or parallel configurations to achieve the desired voltage and capacity. Additionally, a Battery Management System (BMS) is often integrated to monitor and ensure the safe operation of the battery pack.

Why is quality control important in a lithium battery pack assembly?

Consequently, this intricate step paves the way for efficient power transfer and optimal pack performance. Quality control is a cornerstone of the lithium battery pack assembly process.

How does a lithium ion cell selection process work?

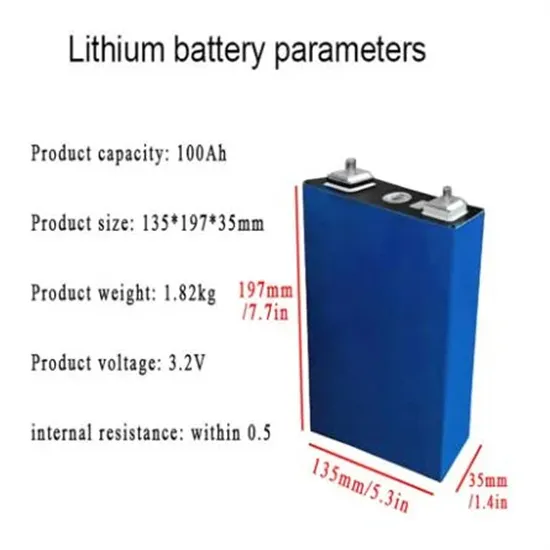

The journey begins with a rigorous cell selection process, where individual lithium-ion cells undergo meticulous testing to ensure consistent quality and performance. Manufacturers measure critical parameters such as cell voltage, capacity, and internal resistance, carefully sorting and grading the cells to eliminate potential imbalances.

More related information

-

Turkmenistan large-cell lithium battery pack

Turkmenistan large-cell lithium battery pack

-

What does the lithium battery pack assembly include

What does the lithium battery pack assembly include

-

Pack lithium battery automatic assembly price

Pack lithium battery automatic assembly price

-

Assembly of two-wheel electric lithium battery pack

Assembly of two-wheel electric lithium battery pack

-

12v lithium battery pack mobile power supply

12v lithium battery pack mobile power supply

-

Togo lithium battery pack wholesale

Togo lithium battery pack wholesale

-

Slovakia high-performance lithium battery pack

Slovakia high-performance lithium battery pack

-

Cuba pack lithium battery wholesale

Cuba pack lithium battery wholesale

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.