(PDF) Material selection and assembly method of battery pack for

Battery packs become the key component in electric vehicles (EVs). The main costs of which are battery cells and assembling processes. The battery cell is indeed priced from

Get Price

How to Assemble a Lithium-Ion Battery Pack with a

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

Get Price

Battery Pack Assembly: Techniques and Materials Used

Electric vehicles rely on lithium-ion batteries for energy storage, making the battery pack the heart of an EV. Its assembly involves intricate processes to ensure reliability, energy

Get Price

(PDF) Design and Development of Electric Two Wheeler

It has major components as: BLDC 900 W motor (3400 rpm), motor controller and lithium ion battery pack. The applied battery pack gives 48 V

Get Price

How to Assemble a Lithium-Ion Battery Pack with a BMS Module:

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed assembly instructions, and testing

Get Price

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Get Price

How to Build Your Own Electric Scooter Battery Pack

Learn how to build your own electric scooter battery pack with this step-by-step guide, from choosing battery cells to assembling and protecting your pack. Customize and improve your

Get Price

Design of Lithium-ion battery packs for two-wheeled

Abstract and Figures The design of Lithium-ion battery pack to meet the power requirements of two-wheeled electric bikes for tropical

Get Price

Automated assembly of Li-ion vehicle batteries: A feasibility study

Electric Vehicles (EVs) with rechargeable Lithium-Ion batteries (Li-ion) are at the forefront of the global trend for lower-emission transportation and decarbonisation. Capable

Get Price

Replacement Battery For Balance Scooter Board 36V

Lithium Battery For Smart Self Balancing Electric Unicycle balance two Wheel 36v 4400 mAh. HIGH-QUALITY HOVER BOARD REPLACEMENT PART -

Get Price

Designing and CFD Analysis of Two

Out of the several existing battery technologies, the Lithium-ion battery technology is primarily used because of its high specific power, energy density, longer life cycle, reduced weight, and

Get Price

Complete Guide to Lithium Battery Pack Design and Assembly

A lithium battery pack is not just a simple assembly of batteries. It is a highly integrated and precise system project. It covers multiple steps, including cell selection,

Get Price

Lithium Battery Packs | BigBattery | Your Source for

"Big Battery made converting our 48v lead acid EZGO cart to lithium a breeze. Our cart is lighter, faster and the range went up dramatically using just a single

Get Price

MotoTec Electric Trike 48v 1000w Lithium

It''s like a three wheel Segway but at a fraction of the price! Powered by a 1000 watt front wheel hub motor with speeds up

Get Price

How are Lithium-ion Battery Packs Manufactured?

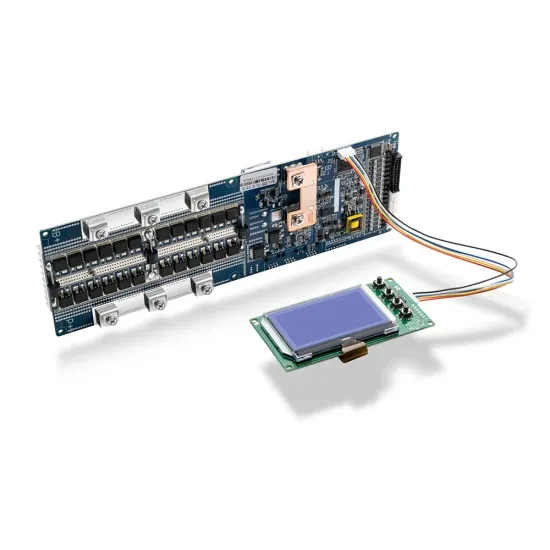

Lithium-ion battery packs are manufactured through a meticulous process that includes two key parts: the Battery Management System (BMS) and the battery pack assembly. The BMS is

Get Price

Design and Manufacturing Challenges in Lithium

In this blog, we will delve into the complexities of designing and manufacturing lithium batteries for two-wheelers, highlighting the hurdles that

Get Price

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

In this guide, we''ll walk you through everything you need to know – from the basics of what a battery pack is, to the tools and materials required, the step-by-step assembly

Get Price

TWO WHEELER / EV PACKS

Our Two-Wheeler portfolio consists of high-quality packs either in LFP and NMC cells. Our wide portfolio comes in different voltages and capacities ranging from 24V-72V and 7Ah-100Ah, are

Get Price

Design of lithium‐ion battery packs for two‐wheeled electric

The design of lithium-ion battery pack to meet the power requirements of two-wheeled electric bikes for Indian conditions is studied here. Theoretical calculations are

Get Price

Beginner-Friendly Tips for Assembling Lithium Battery Packs

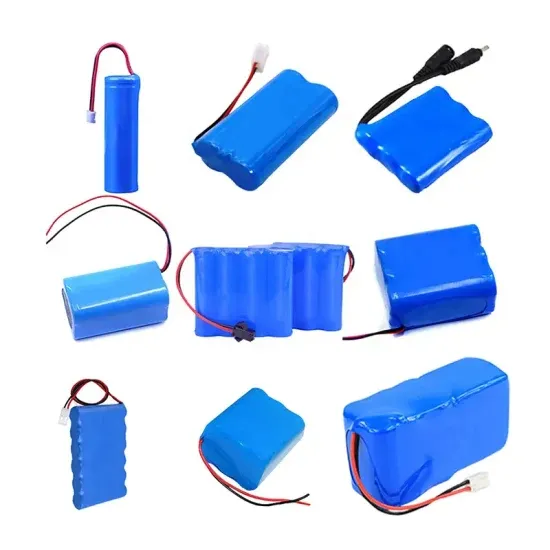

A lithium battery pack is a collection of lithium rechargeable batteries configured to deliver the desired voltage and capacity for specific applications. These packs are widely used

Get Price

How Are Lithium Battery Packs Assembled?

Lithium battery pack assembly is a complex process that involves several steps, from cell selection and testing to final assembly and quality control. The process requires specialized

Get Price

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase

Get Price

DIY a 72V 120AH Lithium Battery Pack for Electric bike

Step-by-step Assembly:Battery pack for a three-wheel Electric Bike. 16s 72v 80A, Li-ion BMS from DALY How to get BMS→: https://s.click.aliexpress /e/_opm

Get Price

Design of Lithium-ion battery packs for two-wheeled vehicles

Abstract and Figures The design of Lithium-ion battery pack to meet the power requirements of two-wheeled electric bikes for tropical conditions is studied here.

Get Price

Design and Manufacturing Challenges in Lithium Batteries for Two

In this blog, we will delve into the complexities of designing and manufacturing lithium batteries for two-wheelers, highlighting the hurdles that industry faces and the

Get Price

How To Make A Lithium Battery Pack With 18650 Cells

Browse the article How To Make A Lithium Battery Pack With 18650 Cells to learn more about lithium-ion battery company Sunpower New Energy and our events.

Get Price

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase plays a critical role in ensuring the

Get Price

Battery Pack Assembly: Techniques and Materials Used

Electric vehicles rely on lithium-ion batteries for energy storage, making the battery pack the heart of an EV. Its assembly involves intricate

Get Price

6 FAQs about [Assembly of two-wheel electric lithium battery pack]

Can lithium-ion battery pack meet the power requirements of two-wheeled electric bikes?

The design of lithium-ion battery pack to meet the power requirements of two-wheeled electric bikes for Indian conditions is studied here. Theoretical calculations are performed based on the technical data collected from various resources in India. In particular, the two-wheeled “Activa 6G” vehicle is considered for the analysis.

What is battery pack assembly?

Battery pack assembly is a critical component of the electric vehicle (EV) ecosystem. The efficiency, safety, and longevity of EVs depend significantly on the quality and precision of their battery packs. Similarly, the performance of EV charging infrastructure is closely linked to the characteristics of these battery systems.

What materials are used for EV batteries?

Aluminum and Steel: Commonly used for battery housing to provide strength while maintaining lightweight properties, essential for EV efficiency. Composite Materials: Increasingly adopted for their high strength-to-weight ratio, contributing to lighter battery packs and improved EV range. Dielectric Films: Prevent electrical shorts within the pack.

What are modular battery packs?

Modular battery packs offer flexibility and ease of replacement, enhancing the longevity of electric vehicles and reducing lifecycle costs. Increased focus on using recyclable and eco-friendly materials will further align battery pack assembly with the goals of a circular economy.

What are the components of an EV battery pack?

An EV battery pack comprises several key elements: Cells: The basic energy storage units, commonly cylindrical, prismatic, or pouch cells. Modules: Groups of cells arranged in series or parallel to achieve the desired voltage and capacity.

What is a battery pack?

Battery packs will increasingly incorporate features tailored for ultra-fast charging and wireless charging technologies, driving innovation in both EVs and EV charging networks. Battery pack assembly is at the heart of the EV revolution, shaping the performance, safety, and sustainability of electric vehicles.

More related information

-

Lithium battery pack assembly equipment

Lithium battery pack assembly equipment

-

Lithium battery pack design and assembly

Lithium battery pack design and assembly

-

Large-cell lithium battery pack assembly

Large-cell lithium battery pack assembly

-

What does the lithium battery pack assembly include

What does the lithium battery pack assembly include

-

Africa customized solar lithium battery pack

Africa customized solar lithium battery pack

-

Large capacity lithium battery pack all

Large capacity lithium battery pack all

-

New cell lithium battery pack

New cell lithium battery pack

-

12v 200A lithium iron phosphate battery pack price

12v 200A lithium iron phosphate battery pack price

Commercial & Industrial Solar Storage Market Growth

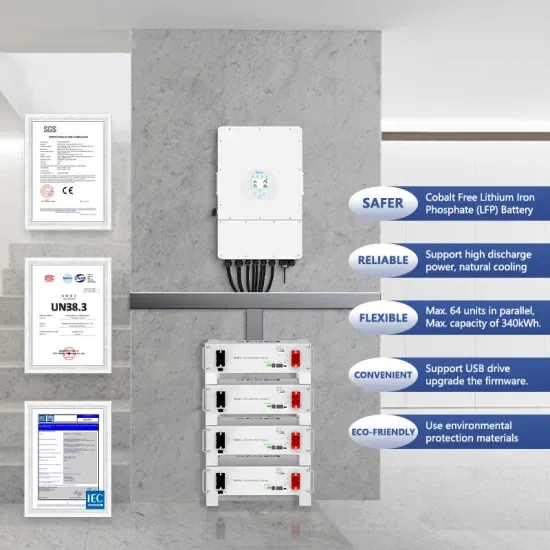

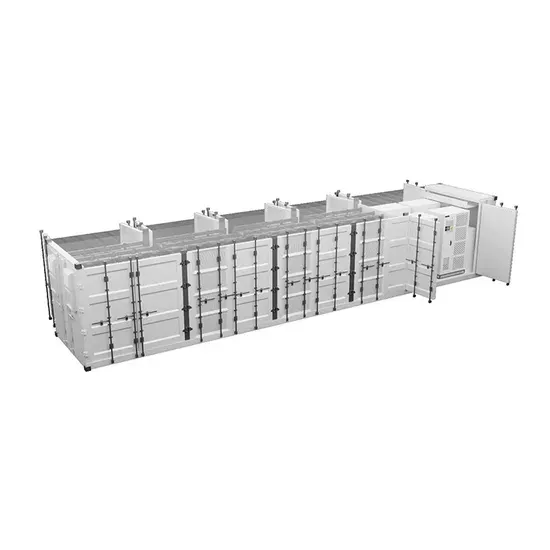

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.