What does a solar panel quality control inspection cover?

Needless to say, it is imperative that solar panels are not only manufactured using high-quality components but that they also undergo

Get Price

Solar panel

A single solar panel can produce only a limited amount of power; most installations contain multiple panels adding their voltages or currents. A

Get Price

Solar Quality Assurance and Quality Control (QA/QC)

Timely identification and correction of quality defects, as well as an adequate implementation of the quality control program, are vital to ensure the optimal long-term performance of solar

Get Price

INDUSTRY LEADING QUALITY CONTROL – CSI Solar – Global

We have adapted the stringent quality-management systems of the automotive industry to PV manufacturing and check every one of our products at 411 different points along the

Get Price

Quality Control for PV Systems, Best Solar Panels

Trina Solar ensures the highest standards of quality for our PV systems across the entire supply chain, to mitigate risk and increase ROI.

Get Price

The Important Role of QAQC in Large-Scale Solar Energy

The International PV Module Quality Assurance Task Force was formed in 2011 to develop standards that can help customers quickly assess a PV product''s ability to withstand regional

Get Price

Solar Panel Quality Check 101: Key Components,

In summary, conducting a quality check during production is crucial to ensuring that solar panels meet the required performance, safety,

Get Price

Enhancing Power Quality in Hybrid Solar-Wind Energy

Abstract: With the increasing adoption of hybrid solar-wind energy systems, ensuring high power quality is crucial for reliable and efficient operation. This review paper examines the integration

Get Price

Solar Quality Control

Searching for a solar panel inspection company? We conduct quality control services for photovoltaic materials and equipment, from PSI, DPI, to testing.

Get Price

The Significance of Quality Assurance in Solar EPC Projects

Importance of Quality Assurance EPC contractors serve as the backbone of any solar project. They are responsible for translating conceptual concepts into fully functioning

Get Price

Solar Quality Control Checklist

This checklist is designed to ensure the proper quality control measures are implemented throughout the solar energy system installation process. It covers inspection points for solar

Get Price

A Review of Control Techniques in Photovoltaic

Complex control structures are required for the operation of photovoltaic electrical energy systems. In this paper, a general review of the

Get Price

Solar Panel Quality Check 101: Key Components, Standards, and

In summary, conducting a quality check during production is crucial to ensuring that solar panels meet the required performance, safety, durability, and compliance standards.

Get Price

Quality Control in Solar Panel Manufacturing: A Guide

Quality control ensures the PV panels manufacturers produce are reliable, efficient, and safe for use. In this article, we will discuss how to implement quality control, common

Get Price

Proposal for a Guide for Quality Management Systems for PV

The International PV Module Quality Assurance Task Force was formed in 2011 to develop standards that can help customers quickly assess a PV product''s ability to withstand regional

Get Price

Control of Solar Energy Systems

Abstract: This work deals with the main control problems found in solar power systems and the solutions proposed in literature. The paper rst describes the main solar power technologies, its

Get Price

What does a solar panel quality control inspection cover?

Needless to say, it is imperative that solar panels are not only manufactured using high-quality components but that they also undergo stringent quality control inspections –

Get Price

Solar Safety Tips: A Checklist for Installation and Maintenance

When it comes to installing and maintaining a solar energy system, safety should always be a top priority. A proper installation and regular maintenance not only ensure that

Get Price

Quality Control and Testing for PV Solar Modules

CEA''s proactive and robust Quality Control and Testing program for PV solar modules proactively identifies and resolves issues at every stage of production

Get Price

How Do Solar Companies Ensure Quality Control? Inside Their

Discover how solar companies ensure top-quality solar systems through rigorous testing, strict standards, skilled teams, and cutting-edge technology.

Get Price

Quality Assurance and Control for Solar Installations

The journey toward achieving excellence in solar installation quality is continuous. With a proactive approach, a commitment to leveraging data analytics, and adherence to rigorous

Get Price

MNRE Issues Revised Quality Control Order for Solar

MNRE Issues Revised Quality Control Order for Solar PV Products The Ministry of New and Renewable Energy (MNRE) has issued the revised

Get Price

The Important Role of QAQC in Large-Scale Solar Energy

When constructing large-scale solar energy projects, quality control (QC) is essential. This includes testing materials used, inspecting physical components such as photovoltaic cells,

Get Price

Power quality analysis of a large grid-tied solar

This study presents practical approaches to a grid-connected solar photovoltaic plant with associated control circuits developed in the time

Get Price

Quality Control and Testing for PV Solar Modules

CEA''s proactive and robust Quality Control and Testing program for PV solar modules proactively identifies and resolves issues at every stage of production – before they impact your business.

Get Price

Quality Control in Solar Panel Manufacturing: A Guide

Quality control ensures the PV panels manufacturers produce are reliable, efficient, and safe for use. In this article, we will discuss how to

Get Price

Smart Soldering in PV: Enhancing Efficiency and

This technique not only enhances solar panel efficiency but also plays a crucial role in reducing the overall cost of photovoltaic (PV) modules.

Get Price

INDUSTRY LEADING QUALITY CONTROL – Canadian Solar –

This commitment to quality extends throughout the production process, with 411 quality control points for our solar modules, from source materials through to the packaging and pre-shipping

Get Price

More related information

-

Fully intelligent solar energy engineering control system distribution box

Fully intelligent solar energy engineering control system distribution box

-

Energy storage container assembly process quality control

Energy storage container assembly process quality control

-

Protection measures for solar energy systems

Protection measures for solar energy systems

-

Residential Concentrated Solar Energy Systems

Residential Concentrated Solar Energy Systems

-

South America Energy Efficient Solar Systems

South America Energy Efficient Solar Systems

-

What is the quality and price of photovoltaic energy storage cabinet solar energy

What is the quality and price of photovoltaic energy storage cabinet solar energy

-

Types of Solar Energy Systems

Types of Solar Energy Systems

-

Solar energy intelligent control system supplier

Solar energy intelligent control system supplier

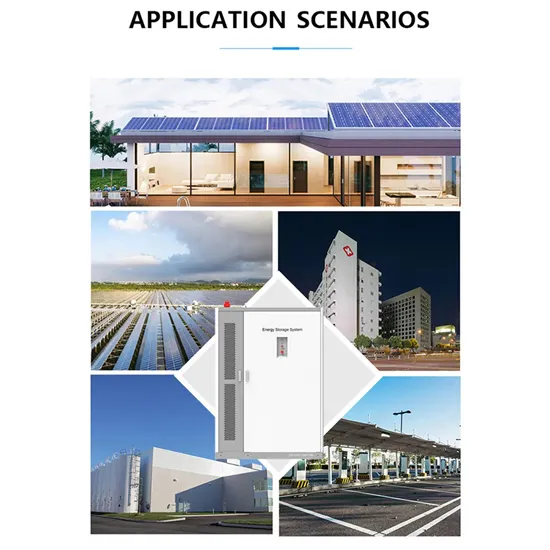

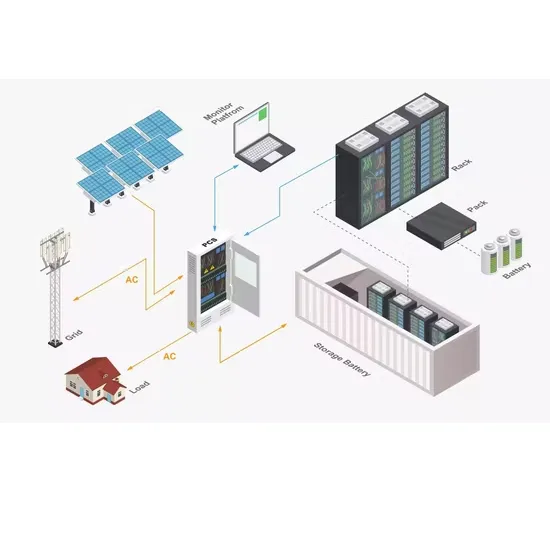

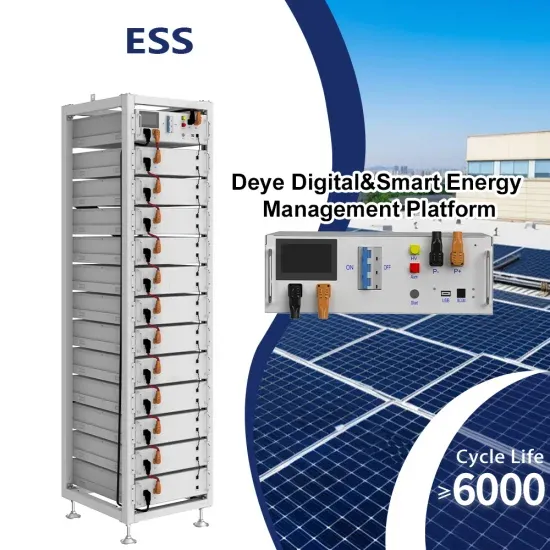

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

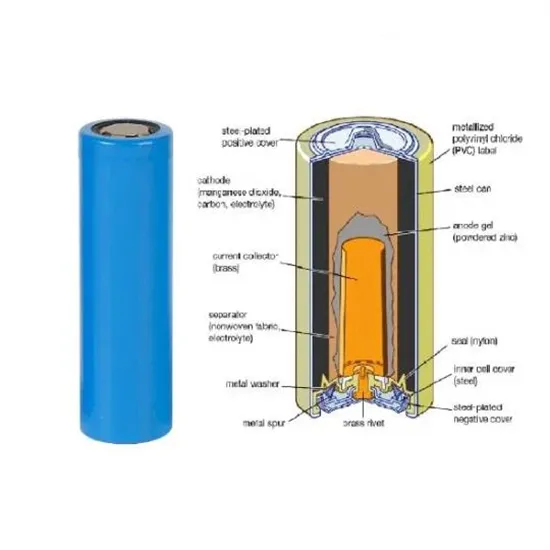

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.