Sampling guideline for inspection and testing of PV modules

15:2016. Visual inspection can be done on a random bas. s and does not require any equipment for inspec-tion. Hence it can be characterised as a general inspection. Similarly, a flash test

Get Price

SILICON SOLAR MODULE VISUAL INSPECTION GUIDE

This document is designed to be used as a guide to visually inspect front-contact poly-crystalline and mono-crystalline silicon solar photovoltaic (PV) modules for major defects (less common

Get Price

Anomaly Detection and Classification of Solar Photovoltaic Modules

In this study, we explore the application of ViT for anomaly detection and classification in solar PV modules using IR imaging data. Several studies have explored

Get Price

Sampling guideline for inspection and testing of PV

Testing a sample of modules at an operational solar can help identify faults and underperformance in the wider plant, but which ones to

Get Price

Field Inspection Checklist For Rooftop Photovoltaic

The checklist covers 19 items to inspect, including verifying the PV module installation matches approved plans, proper grounding and bonding, required

Get Price

Improving photovoltaic module inspection with convolutional

As solar energy adoption continues to grow globally, ensuring the optimal performance and longevity of photovoltaic (PV) modules is crucial for maximizing energy

Get Price

Should The Sky Be The (Acceptable Quality) Limit? A

Through this article, we are going to define each of those terms and go through a practical 30MW project example on how to calculate each

Get Price

A Maintenance Guide for PV System Safety and

The article outlines maintenance procedures for photovoltaic systems, including inverters, charge controllers, PV arrays, and battery banks.

Get Price

Quality, not quantity: the importance of solar module inspection

Pre-shipment inspections: random testing of finished modules before shipment, including performance measurement, electroluminescence imaging, visual inspection and insulation

Get Price

Applied imagery pattern recognition for photovoltaic modules

We present a literature review of Applied Imagery Pattern Recognition (AIPR) for the inspection of photovoltaic (PV) modules under the main used spect

Get Price

Development of a Visual Inspection Checklist for Evaluation

A visual inspection checklist for the evaluation of fielded photovoltaic (PV) modules has been developed to facilitate collection of data describing the field performance of PV modules.

Get Price

Annexure A Pre-dispatch Inspection Protocol for Crystalline

A. PRE-DISPATCH INSPECTION PROCEDURE Objective: The objective of this document is to establish General inspection protocol with objectivity for verification of Quality Parameters of

Get Price

Regulations on Sampling and Inspection of Photovoltaic

How to test a solar PV module? Sampling for testing of PV modules comprises the procedures involved to select a part of PV modules from the entire solar PV plant for inspection and it

Get Price

Best practice guide module field inspection

This chapter outlines the most common in-field inspection techniques for assessing the health of PV modules. Note that we are focusing on in-field inspection techniques available in the PV

Get Price

Pseudorandom Sequence Coded Electroluminescence Imaging

The inspection for photovoltaic (PV) module is mainly used in darkroom based on electroluminescence (EL) imaging. To improve the universality and anti-interference

Get Price

Field Inspection Checklist For Rooftop Photovoltaic PV Systems

The checklist covers 19 items to inspect, including verifying the PV module installation matches approved plans, proper grounding and bonding, required markings, signs and labels, correct

Get Price

Sampling guideline for inspection and testing of PV modules

Sampling guideline for inspection and testing of PV modules in the field an help identify faults and underperformance in the wider plant, but which ones to choose? Authors from Mahindra Teqo

Get Price

Inspection Checklist Guide for PV Systems in One

SECTION 1: Field Inspection Guide for Rooftop Photovoltaic (PV) Systems Standard Plan Make sure all PV system AC/DC disconnects and circuit breakers are in the open position and verify

Get Price

AUTOMATIC CLASSIFICATION OF DEFECTIVE

Since PV modules are made by series connections of PV cells, defects in cells are pointed out as a major cause of module output degradation. The main problem in PV module inspection is

Get Price

Solar PV Post-Evaluation Checklist

This procedure includes system nameplate rating (kW), solar irradiance measurement (W/m2) and module cell temperature (C). Procedure is best conducted during consistent weather

Get Price

Module defect detection and diagnosis for intelligent maintenance

The energy production efficiency of photovoltaic (PV) systems can be degraded due to the complicated operating environment. Given the huge installed capacity of large-scale

Get Price

Inspection Checklist Guide for PV Systems in One

Not all items outlined in this section are relevant to each PV system. This inspection reference details most of the issues that relate to the PV system during the inspection process.

Get Price

Inspection and condition monitoring of large-scale photovoltaic

The massive growth of PV farms, both in number and size, has motivated new approaches in inspection system design and monitoring. This paper presents a review of

Get Price

How to Use Electroluminescence (EL) Imaging to

Improper installation and handling procedures can result in significant PV module damage. The combination of EL and visual inspections

Get Price

Inspection and Testing Guidelines

Documentation, commissioning, tests and inspection [55] IEC TS 62446-3:2017- Photovoltaic (PV) systems - Requirements for testing, documentation and maintenance - Part 3:

Get Price

Should The Sky Be The (Acceptable Quality) Limit? A

Through this article, we are going to define each of those terms and go through a practical 30MW project example on how to calculate each parameter for the solar PV module

Get Price

6 FAQs about [What are the photovoltaic module random inspection items ]

What is sampling for testing of PV modules?

e essential information which can be used efectively to troubleshoot any problems arising within the system. Sampling for testing of PV modules comprises the procedures involved to select a part of PV modules from the entire solar PV plant for inspection and it should a

What is IR ographic inspection of PV modules?

ks and potential-induced degradation (PID) in the module, which afect the overall performance of the module. The IR ther ographic inspection of PV modules is performed to detect non-conformities such as hotspot and diode failure. During thermo-graphic inspection the evalu

What if a solar PV module sample is rejected?

A solar PV module sample will be considered to be rejected due to its observable quality defects if any one of the following conditions are met: If any single observed defect has been evaluated as a Severity of 5. A Severity of 5 indicates a major quality issue; a critical failure or a fraudulent module.

What is a severe rating on a solar PV module?

The schematics in the Terminology section describe where each component is found on a common solar PV module. A Severity Rating is also defined to give users guidelines on how concerning a particular defect may be.

Are all items outlined in this section relevant to a PV system?

Not all items outlined in this section are relevant to each PV system. This inspection reference details most of the issues that relate to the PV system during the inspection process. All California Electrical Code (CEC), California Residential Code (CRC), California Building Code (CBC) and California Fire Code (CFC) references are noted.

How do you know if a photovoltaic module is bad?

Where cells have become shiny or changed colour locally, cells have a poor or degrading anti-reflective coating which is an indicator of poor module performance. “IEC 61215: Crystalline silicon terrestrial photovoltaic (PV) modules - Design qualifications and type approval 2nd Edition,” International Electrotechnical Commission, Geneva, 2005.

More related information

-

What is a double-glass photovoltaic module

What is a double-glass photovoltaic module

-

Photovoltaic project component random inspection ratio

Photovoltaic project component random inspection ratio

-

What is the energy storage battery module of photovoltaic power station

What is the energy storage battery module of photovoltaic power station

-

What is the output value of 6GW photovoltaic module cells

What is the output value of 6GW photovoltaic module cells

-

Moldova photovoltaic module project

Moldova photovoltaic module project

-

Libya photovoltaic module project construction

Libya photovoltaic module project construction

-

The photovoltaic company with the largest module exports

The photovoltaic company with the largest module exports

-

Huawei undertakes photovoltaic module project

Huawei undertakes photovoltaic module project

Commercial & Industrial Solar Storage Market Growth

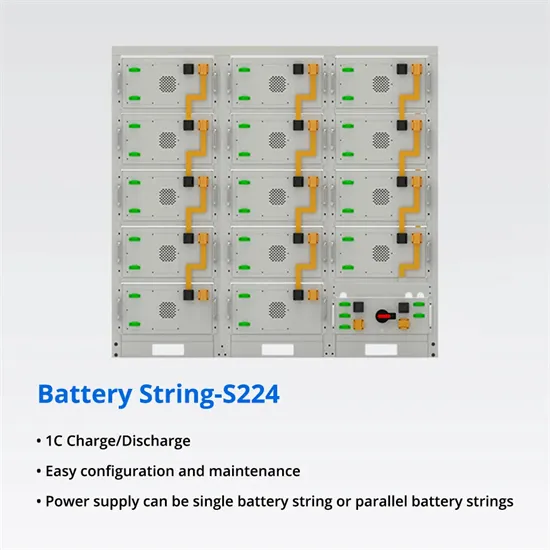

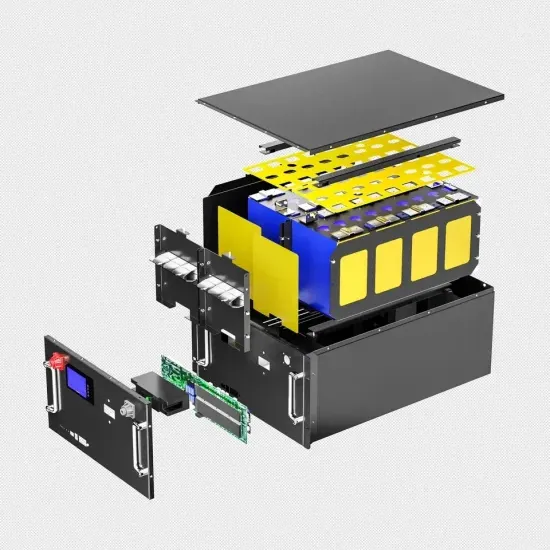

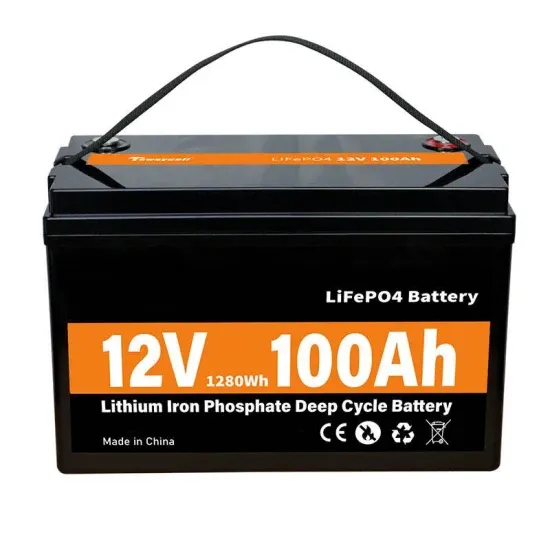

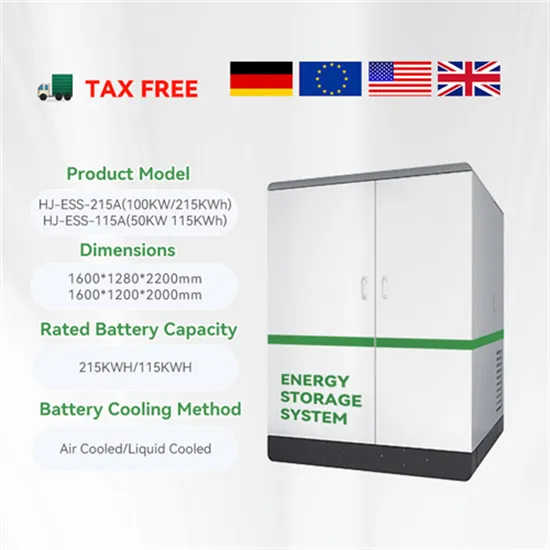

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.