Best practices for solar system commissioning and acceptance

Before commercial operations start, solar systems need to pass a set of acceptance and performance tests conducted by the Engineering, Procurement and Construction (EPC)

Get Price

Assessment of Performance loss rate of PV Power systems

What is IEA PVPS Task 13? Within the framework of IEA PVPS, Task 13 aims to provide support to market actors working to improve the operation, the reliability and the quality of PV

Get Price

Quantification of Technical Risks in PV Power systems

Operational data from PV systems in different climate zones compiled within the project will help provide the basis for estimates of the current situation regarding PV reliability and performance.

Get Price

How many units are sampled for solar energy quality inspection?

The scale of a solar energy project significantly impacts the size of the sample used during inspections. Typically, larger installations—such as utility-scale solar farms—require a

Get Price

Inspection and Testing Guidelines for Large-Scale Solar

In all cases, the work and interventions in construction and during inspection and maintenance of a PV array shall be considered works/interventions under voltage.

Get Price

Solar panel inspection techniques and prospects

Therefore, effective inspection of PV plants under various environmental conditions remain one of the major goals of electrical power utilities companies. In most of the cases, PV

Get Price

Solar Energy Quality Infrastructure in India

Executive Summary This report is about the quality of infrastructure (QI) used in renewable energy installations, pertaining specifically to solar PV and solar thermal. The study is first of

Get Price

Solar Photovoltaic System Cost Benchmarks

The U.S. Department of Energy''s solar office and its national laboratory partners analyze cost data for U.S. solar photovoltaic systems to develop cost

Get Price

Best practices for solar system commissioning and acceptance

Engineering, Procurement and Construction (EPC) contractor. This is the process of assuring safe operation of a solar photovoltaic (PV) system and making sure it is compliant with

Get Price

Solar (PV ) Performance Ratio Assessment | TÜV SÜD

TÜV SÜD offers abridged expert assessment using standard PV components and system-related energy yield reduction factors. Our detailed expert assessment covers investment decisions

Get Price

Inspection and condition monitoring of large-scale photovoltaic

This paper aims to provide a detailed state-of-the-art review of the current research on innovative, optics-based characterization tools for PVM inspection specifically adapted for

Get Price

Sampling guideline for inspection and testing of PV modules

If the PV plant is operational then the module selection should be made as per the inverter performance.

Get Price

Fault Detection and Classification for Photovoltaic

The deployment of solar photovoltaic (PV) panel systems, as renewable energy sources, has seen a rise recently. Consequently, it is

Get Price

End of warranty inspections in solar PV power plants

Asset management | Examining a PV power plant to ascertain its health is a key measure when warranties for components expire. Romain Elsair and Marcos Blanco of Greensolver outline

Get Price

Inspection and Testing Guidelines for Large-Scale Solar

1 SCOPE These Guidelines provide information on the Inspection and Testing procedures to be carried out by the eligible consumer at the end of the construction of a Large-Scale Solar PV

Get Price

Inspection techniques in photovoltaic power plants: A review of

According to the International Energy Agency (IEA), the energy sector accounted for 34.17 GtCO 2eq in 2021 (International Energy Agency Global Energy Review, 2021),

Get Price

SILICON SOLAR MODULE VISUAL INSPECTION GUIDE

ABOUT THIS DOCUMENT This document is designed to be used as a guide to visually inspect front-contact poly-crystalline and mono-crystalline silicon solar photovoltaic (PV) modules for

Get Price

Quantification of Technical Risks in PV Power systems

What is IEA PVPS Task 13? Within the framework of IEA PVPS, Task 13 aims to provide support to market actors working to improve the operation, the reliability and the quality of PV

Get Price

Optimal Methodology for Forecasting Performance

In this paper, an optimal methodology for forecasting the performance loss rate (PLR) of photovoltaic (PV) systems is presented using

Get Price

Performance ratio

Here the performance ratio acts as an indicator and can prompt more detailed inspection of the PV plant so that, for example, soiling of the PV modules is removed or defective components

Get Price

Solar Photovoltaic: SPECIFICATION, CHECKLIST AND GUIDE

The RERH specifications and checklists take a builder and a project design team through the steps of assessing a home''s solar resource potential and defining the minimum structural and

Get Price

Fundamentals of the commissioning

AbstrACt This paper presents the minimum aspects to consider for the commissioning of large-scale PV plants. This methodology has been successfully implemented in the commissioning

Get Price

Procedure for Measuring and Reporting the Performance of

This document includes definitions, calculations and measurements of building energy use for use in energy performance analyses and is provided by the National Renewable Energy

Get Price

Solar inspections 101: A guide to the solar inspection

Solar inspection checklist The solar inspection process is one of the most time-consuming parts of any company''s operations, from design to installation. PV

Get Price

Understanding Solar Photovoltaic System Performance

This report presents a performance analysis of 75 solar photovoltaic (PV) systems installed at federal sites, conducted by the Federal Energy Management Program (FEMP) with support

Get Price

6 FAQs about [Photovoltaic project component random inspection ratio]

Can imaging technology be used to analyze faults in photovoltaic (PV) modules?

The massive growth of PV farms, both in number and size, has motivated new approaches in inspection system design and monitoring. This paper presents a review of imaging technologies and methods for analysis and characterization of faults in photovoltaic (PV) modules.

What is sampling for testing of PV modules?

e essential information which can be used efectively to troubleshoot any problems arising within the system. Sampling for testing of PV modules comprises the procedures involved to select a part of PV modules from the entire solar PV plant for inspection and it should a

What should be included in a PV system inspection?

Inspection of the PV system shall at least verify that:all circuits, protective devices, switches and terminals are suitably labe ed to the requirements of IEC 60364 and SASO IEC 62548.all PV string combiner boxes carry a warning label indicating that active parts inside the boxes are fed from a PV array and may still be energize

What are the future trends in PVS inspection?

The prediction of the future trends in PVS inspection is a real challenge due to the rapid evolution of technologies and user needs. However, it is obvious that the massive yearly growth of PV farms together with other renewable energy sources is necessary to ensure energy security while moving away from fossil and nuclear energy.

What is photovoltaic risk analysis?

Photovoltaic (PV) risk analysis serves to identify and reduce the risks associated with invest-ments in PV projects. The key challenge in reacting to failures or avoiding them at a reasonable cost is the ability to quantify and manage the various risks.

What are the disadvantages of PV module inspection?

The conventional approach to PV module inspection is to use a hand-held infrared sensor and perform visual inspection in-situ by a human operator. The main disadvantages of this method, when applied to a large-scale PV power plant, are that it is time-consuming and costly .

More related information

-

What are the photovoltaic module random inspection items

What are the photovoltaic module random inspection items

-

Belgian photovoltaic power station energy storage project bidding

Belgian photovoltaic power station energy storage project bidding

-

Bulgarian photovoltaic solar energy project

Bulgarian photovoltaic solar energy project

-

Ghana Kumasi Photovoltaic Power Generation and Energy Storage Project

Ghana Kumasi Photovoltaic Power Generation and Energy Storage Project

-

Photovoltaic module intelligent production project

Photovoltaic module intelligent production project

-

Photovoltaic project photovoltaic modules

Photovoltaic project photovoltaic modules

-

Southeast Asia Photovoltaic Module Project

Southeast Asia Photovoltaic Module Project

-

Mali Photovoltaic Power Station Energy Storage Project

Mali Photovoltaic Power Station Energy Storage Project

Commercial & Industrial Solar Storage Market Growth

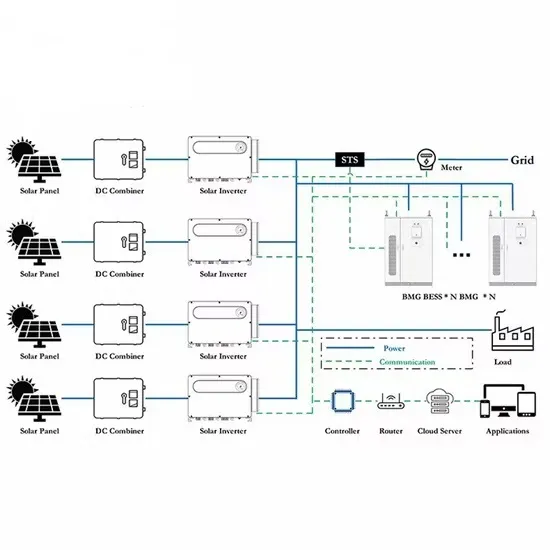

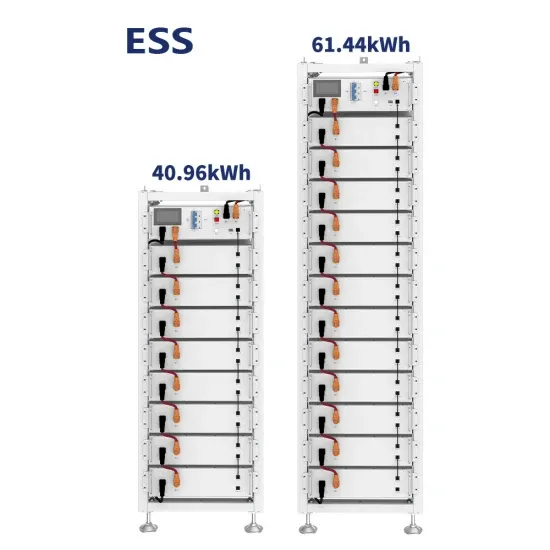

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.