Function Introduction Of Variable Frequency Control

The variable frequency control cabinet is usually designed with circuit breaker components, which are connected with the incoming power

Get Price

What is the purpose of a frequency converter?

The frequency conversion control cabinet is an electrical device used to adjust the operating frequency of the motor. It can effectively reduce energy loss and improve the

Get Price

Analysis of the main functions and applications of frequency converter

The following will discuss the main functions of the inverter control cabinet in detail and analyze its application in different fields. One of the core functions of the frequency

Get Price

How to choose a frequency conversion control cabinet

Remote control and communication function: In a system with a high degree of automation, the frequency conversion control cabinet needs to be able to communicate with the host

Get Price

Frequency conversion control cabinet-Shouke Yuantuo|A

Frequency conversion control cabinet The frequency conversion control cabinet is mainly used to adjust the working frequency of the equipment, reduce energy loss, start the equipment

Get Price

The Role of Frequency Conversion Cabinets in Modern Power

Frequency conversion cabinets are specialized electrical enclosures designed to regulate and adapt the frequency of power supplied to various systems. They serve as a

Get Price

Draught fan frequency conversion cabinet with fast switch function

Automatic switching between frequency conversion and power frequency is achieved when the frequency converter breaks down, accidents affecting production due to shutting down are

Get Price

Analysis Of Function Characteristics Of Frequency Conversion

The general design scheme of frequency converter control cabinet includes isolating switch components, which are connected with three-phase five-wire switching power supply, which

Get Price

Wireless frequency conversion cabinet with shock absorption function

The wireless frequency conversion cabinet has the advantages of reasonable design and artful concept, dual shock absorption design is adopted torealize a good shock absorption function,

Get Price

Frequency conversion cabinet, frequency control cabinet,

East China Industrial Control Frequency Control Cabinet|Intelligent motor speed control and energy saving expert, adapting to /Siemens/Schneider mainstream frequency converter.

Get Price

Design of Common Low Voltage Frequency Conversion Control

Before designing a frequency conversion control system, you must understand the system configuration, working mode, environment, control method, and customer specific

Get Price

Water pump frequency conversion integrated control cabinet

1. Core functions Frequency conversion speed regulation: The water pump variable frequency control integrated cabinet uses advanced frequency conversion speed

Get Price

The Function of Low-voltage Frequency Conversion Cabinet in

3 days ago· Today, Derun Electric''s editor will talk about the role of low voltage frequency conversion cabinet in coal-fired power plant. In general, the core role of * * LV frequency

Get Price

Design of Common Low Voltage Frequency Conversion Control Cabinet

Before designing a frequency conversion control system, you must understand the system configuration, working mode, environment, control method, and customer specific

Get Price

CN215990547U

The utility model relates to the technical field of frequency conversion cabinets, and discloses an intelligent frequency conversion cabinet with dehumidification and drying functions for oil

Get Price

Customization of high-voltage frequency conversion cabinet

Synchronous switching function (optional synchronous switching cabinet): achieve undisturbed switching between power frequency operation and variable frequency operation of the motor,

Get Price

Frequency Conversion Control Cabinet

The frequency conversion control cabinet is mainly used to adjust the working frequency of the equipment, reduce energy consumption, and can start the equipment smoothly, reducing the

Get Price

Frequency conversion control cabinet: efficient and energy-saving

As a key equipment in the field of modern industrial automation, frequency conversion control cabinets are becoming an important choice for enterprises to improve

Get Price

CN109039024A

The invention discloses a kind of frequency converter cabinet bodies with safeguard function, including outer case, the two sides of the bottom of outer case inner wall are fixedly connected

Get Price

What is the function of the frequency converter in the frequency

What is the function of the frequency converter in the frequency conversion control cabinet ? I. Adjust the motor speed The primary function of a frequency converter (VFD) is to adjust the

Get Price

OEM Custom Frequency Conversion Cabinet Manufacturers

The Frequency Conversion Cabinet comes with a built-in PID function and a PID DISABLE function. This allows for precise control of processes that require feedback and adjustment,

Get Price

Understanding How Frequency Conversion Cabinets Work

Frequency conversion cabinets control motor speed by adjusting electrical frequency, improving energy efficiency, reducing waste, and enhancing equipment performance.

Get Price

The Working Principle of Frequency Conversion Water Pump Control Cabinet

The whole system of intelligent frequency conversion constant pressure water supply energy-saving control cabinet is composed of four pumps, one inverter, one PLC and

Get Price

A complete guide to setting parameters of frequency

In the field of modern industrial automation, the frequency conversion control cabinet can achieve precise motor control, protect equipment from overload

Get Price

A complete guide to setting parameters of frequency conversion

In the field of modern industrial automation, the frequency conversion control cabinet can achieve precise motor control, protect equipment from overload and damage, and improve the safety

Get Price

Analysis Of Function Characteristics Of Frequency

The general design scheme of frequency converter control cabinet includes isolating switch components, which are connected with three-phase five-wire

Get Price

More related information

-

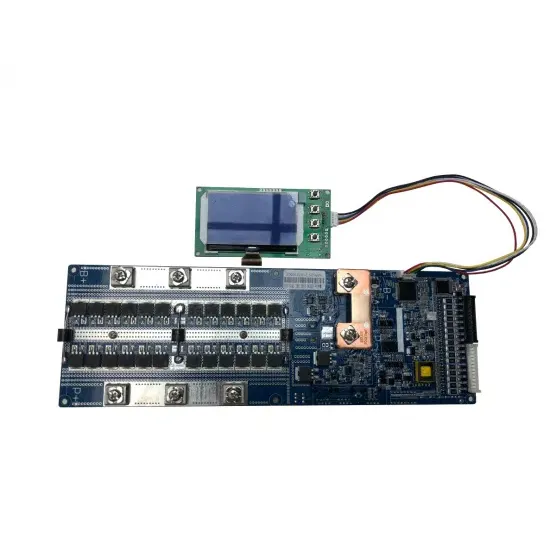

90kW frequency conversion cabinet inverter module

90kW frequency conversion cabinet inverter module

-

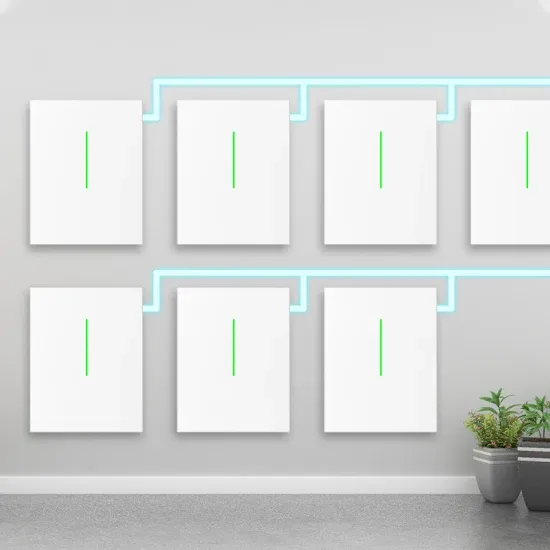

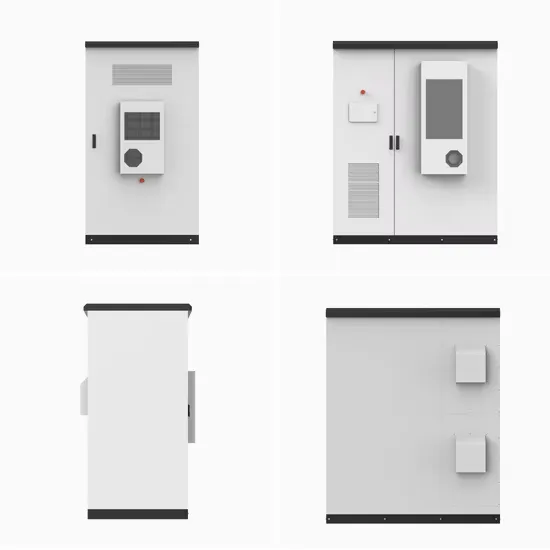

How to install the new energy battery cabinet for conversion equipment

How to install the new energy battery cabinet for conversion equipment

-

Battery cabinet management system BMS main function

Battery cabinet management system BMS main function

-

Energy battery cabinet nitrogen filling function

Energy battery cabinet nitrogen filling function

-

Conversion efficiency of industrial frequency inverter and high frequency inverter

Conversion efficiency of industrial frequency inverter and high frequency inverter

-

The function of base station power storage cabinet

The function of base station power storage cabinet

-

The function of 35kv energy storage cabinet

The function of 35kv energy storage cabinet

-

Does DC frequency conversion require an inverter

Does DC frequency conversion require an inverter

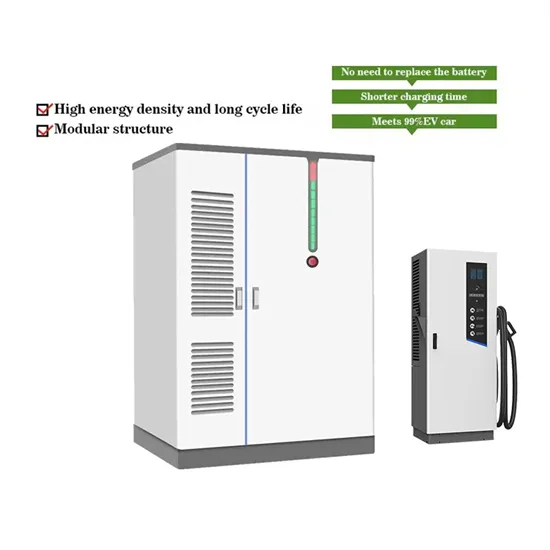

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.