The Anatomy of a Solar Cell: Constructing PV Panels

Discover the remarkable science behind photovoltaic (PV) cells, the building blocks of solar energy. In this comprehensive article, we delve

Get Price

How to manufacture a photovoltaic module

Learn how to assemble and produce high-quality solar modules. By understanding the photovoltaic module production process and to learn which

Get Price

Solar Photovoltaic Manufacturing Basics

Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing steps that typically occur separately from each other.

Get Price

Solar Panel Construction

We explain how silicon crystalline solar cells are manufactured from silica sand and assembled to create a common solar panel made up of 6 main

Get Price

Solar Photovoltaic Panel Production Line Assembly

Solar Photovoltaic Panel Production Line is a high-tech manufacturing process that converts sunlight into electricity using photovoltaic cells, involving cutting,

Get Price

Solar Panel Structure

Learn about the structure of solar panels, solar cells, and mounting designs. Discover how solar structures are built for durability and maximum

Get Price

How to Assemble a Solar Panel: Step-By-Step Guide

Here also our guide which helps you to assemble a solar panel. Did you know that you can assemble a solar battery at home by your own hands? With our

Get Price

Solar panel manufacturing process: from cell to module

During lay-up, solar cells are stringed and placed between sheets of EVA. The next step in the solar panel manufacturing process is lamination.

Get Price

Solar Mounting Structures Archive

The SteelCore Ground Mount system is designed to provide robust and cost-effective support for solar panels, crafted exclusively from high-grade . . .

Get Price

How to Assemble a Solar Panel: Step-By-Step Guide

Here also our guide which helps you to assemble a solar panel. Did you know that you can assemble a solar battery at home by your own hands? With our lifehacks it is easy. First of all,

Get Price

The Anatomy of a Solar Cell: Constructing PV Panels Layer by

Discover the remarkable science behind photovoltaic (PV) cells, the building blocks of solar energy. In this comprehensive article, we delve into the intricate process of PV

Get Price

DIY Solar Panel Mounts: Install Your Panels on a Budget

Solar energy is more accessible than ever, but installation costs can still add up for homeowners. Cutting costs is a priority for many solar

Get Price

Assembled satellite mock-up structure and solar array

The solar panels in the deployed configuration are shown in Fig. 13. The system assembly consists of two solar panels packs, comprising three solar panels each.

Get Price

How are solar panels assembled? | NenPower

Solar panels consist of various components, including photovoltaic cells, glass covers, backing materials, junction boxes, and

Get Price

Solar Panel Construction

We explain how silicon crystalline solar cells are manufactured from silica sand and assembled to create a common solar panel made up of 6 main components - Silicon PV cells,

Get Price

Solar Panel Structure

Learn about the structure of solar panels, solar cells, and mounting designs. Discover how solar structures are built for durability and maximum efficiency.

Get Price

How are solar panels assembled? | NenPower

Solar panels consist of various components, including photovoltaic cells, glass covers, backing materials, junction boxes, and aluminum frames. Each element plays a crucial

Get Price

An innovative deployable solar panel system for Cubesats

The main hinge, connecting the solar panels assembly to the satellite structure (red in Fig. 5) must allow (and limit ) the rotation of the whole assembly by 90°, from the stowed to

Get Price

Processes for the assembly and production of solar panels

Solar panels convert light into power, converting energy everywhere. However making solar panels requires complex material structures and production processes, read this article to

Get Price

A Guide to Solar Structure Manufacturing Techniques

Understanding Solar Structure Manufacturing: A Deep Dive The global race for cleaner, greener energy has placed solar power at the forefront of the renewable revolution. But while shiny

Get Price

Solar Panel Diagram and Its Components Explained

Focus on the following components when analyzing a photovoltaic module: the photovoltaic cells, the protective glass, and the backsheet. The cells convert light into electrical energy through

Get Price

Solar Panel Installation: Step-by-Step Process

Key Considerations for Solar Panel Installation Solar energy is a form of easy, renewable power that uses solar electricity to provide power. It offers many

Get Price

5 Different Types of Solar Mounting Structure

5 Different Types of Solar Mounting Structure: It includes mounted roof racks, ground-mounted racks, top-of-pole mounted racks, and the like.

Get Price

How To Assemble Solar Panel System?

Learn how to assemble solar panel system step-by-step. Discover essential components, tools, and safety tips for a successful installation.

Get Price

Characteristics and Importance of Ballasted Solar

The mounting structure of solar modules is a critical component, ensuring proper installation and optimal design angles to maximize solar exposure. Choosing

Get Price

Solar Panel Manufacturing Process: Step-by-Step Guide

Learn how solar panels are made in a solar manufacturing plant, including silicon wafer production, cell fabrication, and the assembly of panels into solar modules.

Get Price

Solar Photovoltaic Manufacturing Basics

Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing steps that

Get Price

Solar Panel Mounting Structure

A mounting structure for a solar panel assembly, having a plurality of solar panels, includes a plurality of vertical support legs and a grid assembly. The grid assembly includes a plurality of

Get Price

Engineering and Building a Dual-Axis Follow-the-Sun

Slew Drive for Solar Panels In summary, a slew drive operates through the interaction between a gear ring with internal teeth and a motor

Get Price

More related information

-

Kiribati solar panel assembly

Kiribati solar panel assembly

-

Syria South Solar Photovoltaic Panel Assembly

Syria South Solar Photovoltaic Panel Assembly

-

Single crystal silicon solar panel structure

Single crystal silicon solar panel structure

-

Photovoltaic transparent solar panel assembly

Photovoltaic transparent solar panel assembly

-

Photovoltaic Panel Dual Solar Panel Assembly

Photovoltaic Panel Dual Solar Panel Assembly

-

Power generation solar panel assembly

Power generation solar panel assembly

-

Uzbekistan New Energy Solar Panel Assembly Industry and Commerce

Uzbekistan New Energy Solar Panel Assembly Industry and Commerce

-

Southern Europe non-standard photovoltaic solar panel assembly 550w

Southern Europe non-standard photovoltaic solar panel assembly 550w

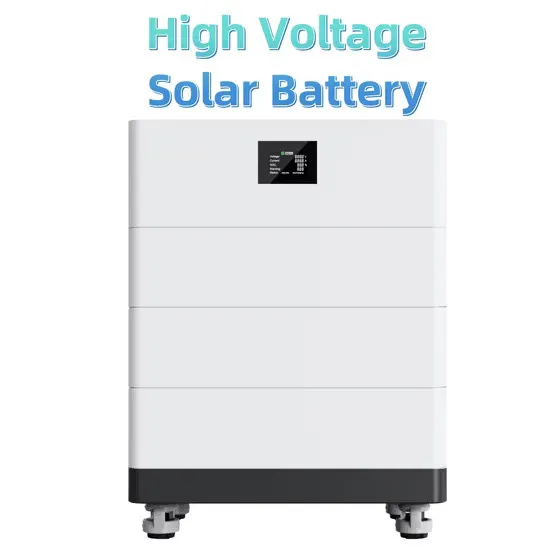

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

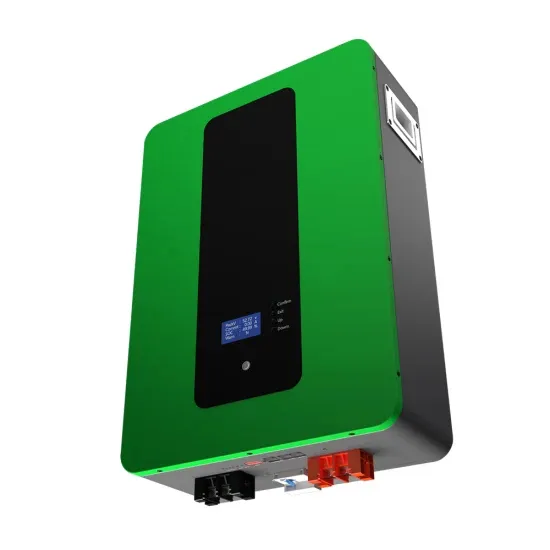

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.