How to Connect a Large or Small Inverter to a Battery

The most common way to connect the inverter to the battery is used in vehicles that have frames that are electrically connected to the

Get Price

Battery + to Inverter + & Inverter

One thing I noticed is that the Battery + ends up connected (After going through the breaker & Anderson Plug) to the Inverter +, but the Inverter

Get Price

2019 Open Road

Okay, I''m fairly new to having a Tiffin coach. Can anyone explain how the new Open Roads charge the coach and chassis batteries? We have a Magnum 2000 inverter if that

Get Price

Inverter Earth to Chassis

I asked about the chassis being connected to the negative of the battery and the earth on the inverter, not about finding a good earth grounding point. You do make a good

Get Price

Negative voltage on ground wire from house battery to inverter

iRV2 Forums > RV SYSTEMS AND TECHNOLOGIES FORUMS > RV Systems & Appliances Negative voltage on ground wire from house battery to inverter iRV2 Google

Get Price

Where to connect Inverter Earth/Ground cable

What is the best place to connect the earth/ground cable from the inverter body? to Battery negative? I use the inverter (1500 watt pure sine wave) as stand alone unit, to plug

Get Price

Battery + to Inverter + & Inverter

One thing I noticed is that the Battery + ends up connected (After going through the breaker & Anderson Plug) to the Inverter +, but the Inverter - is NOT connected to the

Get Price

inverter

Electricity novice here. Thanks for reading! I have a 3000 watt DC to AC inverter attached to a 12V battery bank. The inverter has "DC ground lug" on the exterior of the

Get Price

Grounding question for inverter. : r/electricians

At the inverter: connect chassis ground to a true earth, and optionally connect whichever of DC+/- is ground in your system. Three wire devices: make sure AC ground and AC neutral are both

Get Price

Mod: Lithium Batteries + 3,000w Inverter

Remove the house batteries, old inverter as well as the battery cables that previously connected them to each other. You can repurpose the black/ground

Get Price

Am I supposed to ground the inverter or the battery or both to the

It is important to have a very low resistance path between battery negative terminal and inverter negative terminal. If it is possible to bond them both to the chassis very securely,

Get Price

Another battery question

Replace chassis batteries and measure voltage with the main disconnect switch off. Should read about 12.6 volts (indicating fully charged). If batteries are fully charged, then

Get Price

Charging Chassis Batteries/Coach Batteries

I am new to the Fleetwood Discovery 39S batteries setup and here''s what I have determined how the 2 separate battery banks get charged. I have verified the charging

Get Price

How to Safely Connect a Battery to an Inverter: A Step-by-Step

Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend system life.

Get Price

Inverter installation questions

Cruisers & Sailing Forums > Engineering & Systems > Electrical: Batteries, Generators & Solar Inverter installation questions - neutral, ground, GFCI, etc.

Get Price

How to Use a Power Inverter with a Car Battery

Learn how to use a power inverter with a car battery efficiently; the process, safety tips, and best practices for seamless power conversion.

Get Price

Use vehicle chassis as inverter negative conductor? Pros/Cons

In other words the negative terminal of my inverter would connect to the chassis at the inverter, and the chassis to the battery terminal and the frame of the vehicle would be the

Get Price

Chassis ground of not chassis ground...

In the RV, the battery negative as well as the generator neutral and shore power neutral are all connected to the vehicle chassis. My concern is that, when using the generator

Get Price

How To Connect Batteries In Series and Parallel

To connect batteries in a series, a jumper wire connects a battery''s negative terminal to another battery''s positive terminal. This leaves you with a positive terminal at the

Get Price

How to Safely Connect a Battery to an Inverter: A

Learn how to safely connect your batteries to your inverter with our guide. Avoid common wiring mistakes to optimize performance and extend

Get Price

Can inverter chassis ground connect to negative dc inverter

One possible scenario: the battery negative cable might be disconnected. In grounding and bonding there are 50 ways to go wrong, if you can think of 25 of them you are a

Get Price

Does converter charge chassis battery | Forest River Forums

Since both my house battery and chassis battery connections are literally a few inches apart at the Battery Control Center in the hydraulics/house battery compartment,

Get Price

How To Ground An Inverter In An RV (8 Steps)

The inverter grounding wire to the grounding point must be of the same gauge or thicker than the battery wire. The grounding wire must be

Get Price

How do I ground a 12v battery and an AC inverter?

Do not connect the chassis ground terminal to anything except the vehicle chassis if mounted permanently. Never connect direct to the battery. Only the DC power input terminals

Get Price

Can I connect the inverter''s ground wire to the vehicle

Is it safe (for me and for the components) to connect the grounding wire for the 230V appliances to the vehicle chassis (which is also a common negative for

Get Price

Can I connect the inverter''s ground wire to the vehicle chassis

Is it safe (for me and for the components) to connect the grounding wire for the 230V appliances to the vehicle chassis (which is also a common negative for the leisure and starter batteries.)

Get Price

How to Connect a Large or Small Inverter to a Battery

The most common way to connect the inverter to the battery is used in vehicles that have frames that are electrically connected to the Negative terminal of the battery.

Get Price

6 FAQs about [Battery chassis connected to inverter]

How to connect battery negative terminal to inverter negative terminal?

It is important to have a very low resistance path between battery negative terminal and inverter negative terminal. If it is possible to bond them both to the chassis very securely, and verify that the resulting resistance is very low, then you can do that. To be safe, you should probably run a heavy gauge cable between them.

How do you use a car battery inverter?

Place the inverter on a stable surface 8. Connect the Positive battery clip to the battery positive terminal. 9. Connect the negative battery clip to a metal part of the vehicle frame. 10. Connect an appliance cord plug into the inverter or a USB power cord into the inverter. 11. Turn ON the inverter and use the appliance.

How to connect a battery to an inverter?

The connection between the battery and the inverter should be made using standardized connectors, ensuring that the joints are secure and not loose. In addition, make sure that the cables are securely connected to avoid looseness or poor contact that could lead to inefficiencies.

Are all power inverters compatible with all car batteries?

No, not all power inverters are compatible with every car battery. It’s essential to choose an inverter with the correct input voltage (typically 12V DC for most car batteries). Additionally, the inverter’s wattage should be appropriate for the devices you plan to power. Exceeding the inverter’s power limit can cause overheating or damage.

Do inverters and batteries need to match?

The inverter and batteries must match in terms of voltage, capacity, and power output. If you are using a 12V battery, then the input voltage of the inverter must match the battery voltage. If the specifications of the battery and the inverter do not match, the system will not operate stably and may even damage the equipment.

How to install a car inverter?

1. Make sure the vehicle is parked in a location that does not interfere with traffic. 2. Ensure the vehicle engine is not operating. 3. Open the engine compartment hood. 4. Make sure that the Inverter’s ON/Off switch is set to OFF. 5. Put on safety glasses. 6. Connect the battery clip cables to the Positive and Negative inverter terminals. 7.

More related information

-

Does the micro inverter need to be connected to a battery

Does the micro inverter need to be connected to a battery

-

Lead-acid battery connected to inverter

Lead-acid battery connected to inverter

-

The inverter is always connected to the battery

The inverter is always connected to the battery

-

What kind of battery can be connected to the inverter

What kind of battery can be connected to the inverter

-

Can a 48v large single-cell lithium battery be connected to an inverter

Can a 48v large single-cell lithium battery be connected to an inverter

-

Can a 48v battery be connected to a 12v inverter

Can a 48v battery be connected to a 12v inverter

-

Battery cabinet connected to inverter

Battery cabinet connected to inverter

-

What is the output voltage of the battery connected to the inverter

What is the output voltage of the battery connected to the inverter

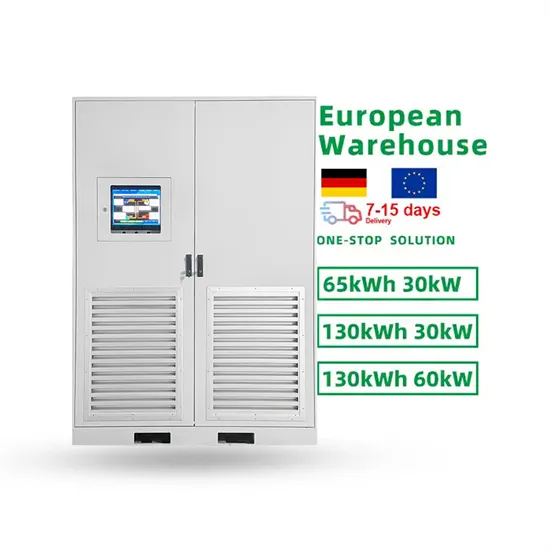

Commercial & Industrial Solar Storage Market Growth

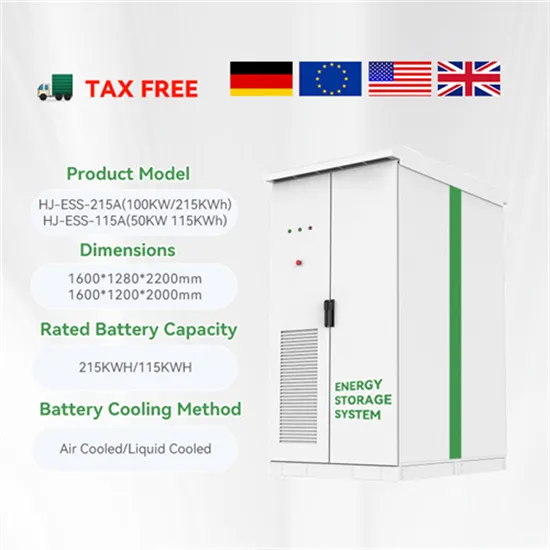

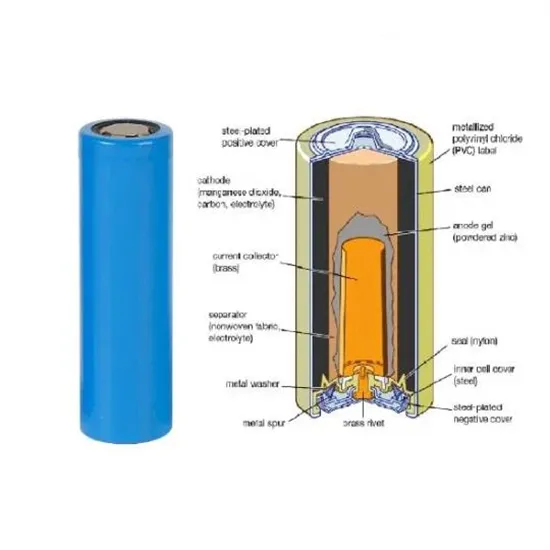

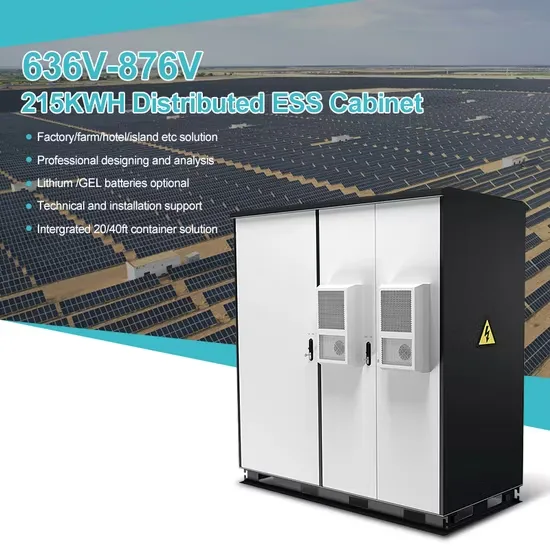

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

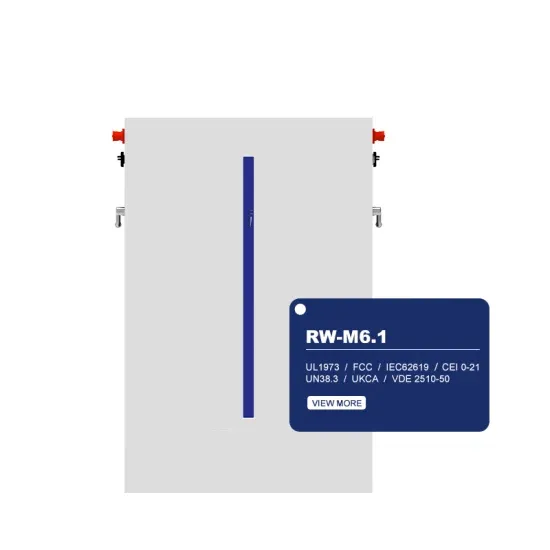

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.