Tungsten oxide nanostructures for all-vanadium redox flow battery

Vanadium redox flow batteries (VRFBs) offer remarkable performance capabilities for renewable energy power plants. However, the kinetics of the VRFBs'' redox reactions are

Get Price

Redox flow battery:Flow field design based on bionic mechanism

All-vanadium redox flow batteries (VRFBs) are pivotal for achieving large-scale, long-term energy storage. A critical factor in the overall performance of VRFBs is the design of

Get Price

Redox Flow Batteries: A Literature Review Oriented to

This paper presents a literature review about the concept of redox flow batteries and its automation and monitoring. Specifically, it is focused on

Get Price

Electrode materials for vanadium redox flow batteries: Intrinsic

The design and future development of vanadium redox flow battery were prospected. Vanadium redox flow battery (VRFB) is considered to be one of the most

Get Price

Why Vanadium? The Superior Choice for Large-Scale

As renewable energy adoption continues to grow, so does the demand for reliable, long-duration energy storage solutions. Vanadium Redox

Get Price

All-vanadium redox flow batteries

All-vanadium redox flow batteries use V (II), V (III), V (IV), and V (V) species in acidic media. This formulation was pioneered in the late eighties by the research group of Dr

Get Price

A comparative study of iron-vanadium and all-vanadium flow battery

The flow battery employing soluble redox couples for instance the all-vanadium ions and iron-vanadium ions, is regarded as a promising technology for large scale energy storage,

Get Price

Development status, challenges, and perspectives of key

Abstract All-vanadium redox flow batteries (VRFBs) have experienced rapid development and entered the commercialization stage in recent years due to the

Get Price

Bringing Flow to the Battery World

In 1984, Maria Skyllas-Kazacos invented the breakthrough flow battery chemistry - the all vanadium RFB. This is a symmetric RFB that

Get Price

Redox Flow Battery: How It Works, Types, Applications, And

The diversity of redox flow battery types highlights various attributes, such as energy density, cost, and scalability. Each type has unique advantages and potential

Get Price

Fact Sheet: Vanadium Redox Flow Batteries (October 2012)

There are many kinds of RFB chemistries, including iron/chromium, zinc/bromide, and vanadium. Unlike other RFBs, vanadium redox flow batteries (VRBs) use only one element (vanadium) in

Get Price

Why Vanadium? The Superior Choice for Large-Scale

In this article, we''ll compare different redox flow battery materials, discuss their pros and cons, and explain why vanadium is the most promising

Get Price

Redox Flow Batteries: Stationary Energy Storages

Functional scheme of an all-vanadium redox flow battery. During charging, the ions of the two electrolytes are forced into higher or lower

Get Price

DOE ESHB Chapter 6 Redox Flow Batteries

These types of membranes are industrially employed in the chloro-alkali process and used in large demonstration-size acidic vanadium and Fe-Cr flow batteries due to low proton

Get Price

Analysis of different types of flow batteries in energy storage field

Different classes of flow batteries have different chemistries, including vanadium, which is most commonly used, and zinc-bromine, polysulfide-bromine, iron-chromium, and iron

Get Price

Bringing Flow to the Battery World

In 1984, Maria Skyllas-Kazacos invented the breakthrough flow battery chemistry - the all vanadium RFB. This is a symmetric RFB that leverages the same electrolyte in both

Get Price

Vanadium redox battery

Different types of graphite flow fields are used in vanadium flow batteries. From left to right: rectangular channels, rectangular channels with flow distributor, interdigitated flow field, and

Get Price

Vanadium Redox Flow Batteries

Guidehouse Insights has prepared this white paper, commissioned by Vanitec, to provide an overview of vanadium redox flow batteries (VRFBs) and their market drivers and barriers.

Get Price

Vanadium redox battery

Different types of graphite flow fields are used in vanadium flow batteries. From left to right: rectangular channels, rectangular channels with flow distributor,

Get Price

Solar energy storage: part 6

Sinovoltaics explains the flow battery, its key feautres and different technology types, including redox flow, membraneless, organic and more types.

Get Price

Redox‐Flow Batteries: From Metals to Organic Redox‐Active

Go with the flow: Redox-flow batteries are promising candidates for storing sustainably generated electrical energy and, in combination with photovoltaics and wind farms, for the creation of

Get Price

Water crossover phenomena in all-vanadium redox flow batteries

Water crossover through the membrane of a vanadium redox flow battery system is not desirable because it floods one half-cell, diluting the vanadium solution on one side and

Get Price

Vanadium Redox Flow Batteries: A Review Oriented to Fluid

This review aims to present and discuss the numerical models developed in this field and, particularly, to analyze different types of flow fields and patterns that can be found in the

Get Price

Analysis of different types of flow batteries in energy

Different classes of flow batteries have different chemistries, including vanadium, which is most commonly used, and zinc-bromine,

Get Price

Why Vanadium? The Superior Choice for Large-Scale Energy

In this article, we''ll compare different redox flow battery materials, discuss their pros and cons, and explain why vanadium is the most promising choice for large-scale energy storage.

Get Price

Polymer Membranes for All-Vanadium Redox Flow

Redox flow batteries such as the all-vanadium redox flow battery (VRFB) are a technical solution for storing fluctuating renewable energies on a

Get Price

Strategies for improving the design of porous fiber felt

All-vanadium redox flow batteries (VRFBs) are ideal for large-scale and long-duration energy storage due to their intrinsic safety, long life,

Get Price

Redox Flow Batteries: potential, alternatives and challenges

The redox flow battery market, although less well known than conventional lithium or solid-state batteries, is gaining momentum as a robust and viable alternative in large-scale,

Get Price

More related information

-

Micro all-vanadium redox flow battery

Micro all-vanadium redox flow battery

-

All-vanadium redox flow battery discharge rate

All-vanadium redox flow battery discharge rate

-

All-vanadium redox flow battery 100mw

All-vanadium redox flow battery 100mw

-

Finnish all-vanadium redox flow battery

Finnish all-vanadium redox flow battery

-

Romanian all-vanadium redox flow battery

Romanian all-vanadium redox flow battery

-

All-vanadium redox flow battery is used

All-vanadium redox flow battery is used

-

Reduction-oxidation all-vanadium redox flow battery

Reduction-oxidation all-vanadium redox flow battery

-

Entering the all-vanadium redox flow battery industry

Entering the all-vanadium redox flow battery industry

Commercial & Industrial Solar Storage Market Growth

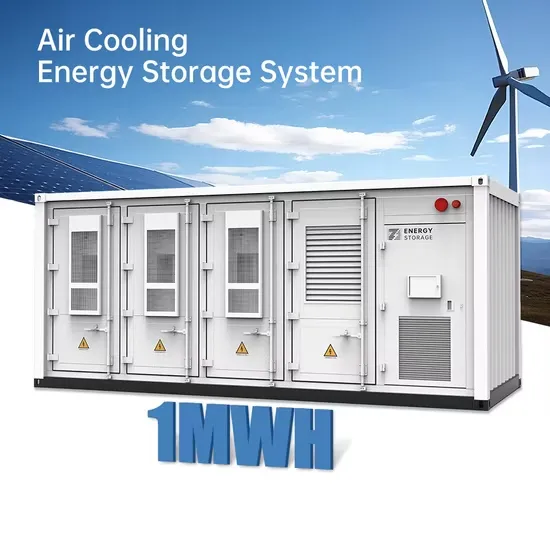

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

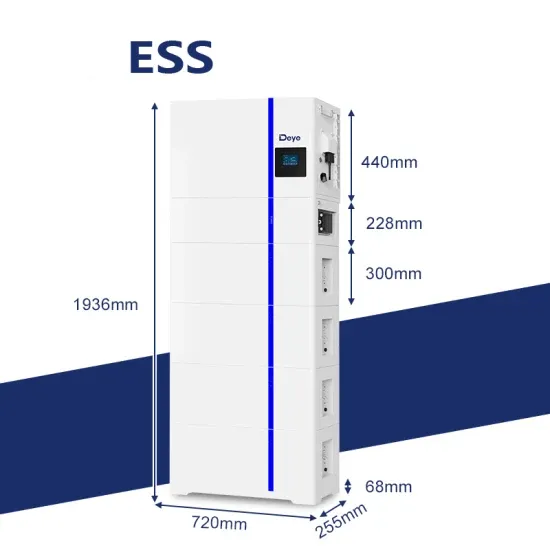

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.