Low Vs High Frequency Inverters/UPS Comparison

High-frequency inverters are known for their advanced technology and efficiency. But what is a high-frequency inverter? At its core, a high-frequency inverter converts DC to AC using

Get Price

Understanding inverter frequency – effects and adjustments

In this comprehensive guide, we delve into the intricacies of inverter frequency, exploring its significance, factors affecting it, and its practical implications.

Get Price

Ferrite Transformer Turns Calculation with Example

In this article, you will learn how to calculate the turns ratio of a ferrite core transformer for high-frequency switch mode power supply inverters. High-frequency ferrite core transformers are

Get Price

Frequency inverter basics

37. Open-loop vector: A complex but effective motor-control method that allows frequency inverters to realize the best characteristics of dc drive control

Get Price

Calculation method of high-frequency transformer turns for

The number of wires in a coil is not necessarily the number of turns. Only when the number of parallel windings is equal to 1, does the number of wires in a coil equal the

Get Price

Voltage Fed Full Bridge DC-DC & DC-AC Converter High

The high frequency transformer, with relatively few primary turns, has extremely low DC resistance, and the IR drop from the DC magnetizing current component is usually not

Get Price

High frequency effects in inverter-fed AC electric machinery

High frequency effects in inverter-fed AC electric machinery Voltage wave reflections at motor terminals HF voltage distribution in armature winding Insulation stress of AC winding at

Get Price

iMars BD3KTL-PS Energy Storage Inverter

3kW energy storage inverter is a bi-directional and high frequency isolated inverter. It is able to generate power from battery to feed the grid (utility) and also can charge the

Get Price

Fundamentals of Inverter–Fed Motors

The Growing Use Of Inverters The long standing desire to be able to adjust the speed of AC induction motors electronically became a reality in the early 1980''s. Called Adjustable Speed

Get Price

Mastering Inverter Switching Frequencies: A

Explore the intricate dance of inverter switching frequencies to optimize energy flow. Master the rhythms of power electronics with our

Get Price

High Frequency Inverter Power Stage Design

For inverter operation above the resonant frequency, the resonant current will flow through the anti-parallel diode before the switch is turned on. During the device turn on

Get Price

Ferrite Transformer Turns Calculation for High-Frequency/SMPS Inverter

On different forums, I often find people asking for help in calculating the required turns for a ferrite transformer they are going to use in high-frequency/SMPS inverters. In a high

Get Price

How to Design Your Own Inverter Transformer

Primary Voltage (Output Voltage) = 12-0-12 volts, that is equal to 24 volts. Output Frequency = 50 Hz Calculating Inverter Transformer Voltage,

Get Price

Transformer Turn Calculation | PDF | Power Inverter

This document discusses calculating the required number of turns for a ferrite transformer used in a high-frequency switching mode power supply (SMPS) inverter.

Get Price

Single-Stage Variable-Turns-Ratio High-Frequency Link Grid

Abstract: In this paper, a technique of variable-turns-ratio high-frequency link inverter is proposed to provide a simple method to achieve multi-level outputs for the isolated

Get Price

Ferrite Transformer Turns Calculation with Example

In this article, you will learn how to calculate the turns ratio of a ferrite core transformer for high-frequency switch mode power supply inverters. High

Get Price

32 Common Faults in Inverters and Their Solutions

Discover the top 32 reasons for inverter failure and how to fix them with our comprehensive troubleshooting guide. Ensure your inverter is always

Get Price

A Review on the Recent Development of High-Frequency Inverters

With the demand for the miniaturization and integration of wireless power transfer (WPT) systems, higher frequency is gradually becoming the trend; thus, the power electronic

Get Price

Nine‐level high‐frequency inverter

In the high-frequency AC (HFAC) power distribution system, problems such as high switching frequency, a complicated circuit configuration

Get Price

Ferrite Transformer Turns Calculation | PDF | Power Inverter

The document discusses how to calculate the required number of turns for a ferrite transformer used in a high-frequency switching mode power supply (SMPS) inverter.

Get Price

Transformer Coil Turns Calculator – Primary and Secondary

Calculate the number of turns in a transformer coil based on voltage, frequency, and core area. Ideal for primary or secondary winding design.

Get Price

Understanding inverter frequency – effects and

In this comprehensive guide, we delve into the intricacies of inverter frequency, exploring its significance, factors affecting it, and its practical

Get Price

Ferrite Transformer Turns Calculation for High

On different forums, I often find people asking for help in calculating the required turns for a ferrite transformer they are going to use in

Get Price

Calculation method for the number of turns of high-frequency

Calculation method for the number of turns of high-frequency transformers in switching power supplies. Calculation formula: N=0.4 (l/d) to the power of the root. (Among

Get Price

Inverter Basics | inverter

High-power inverters generate heat, typically managed by a fan. In elevated temperatures, an inverter might struggle to sustain continuous

Get Price

Design and Construction of a High-Frequency Transformer of

Parameter Analysis: The number of turns, core, magnetic flux density, frequency, and copper losses serve as their primary summaries. In order to determine the trade-offs and

Get Price

Transformer Turn Calculation | PDF | Power Inverter

This document discusses calculating the required number of turns for a ferrite transformer used in a high-frequency switching mode power supply (SMPS)

Get Price

Ferrite Transformer Turns Calculation for High-Frequency/SMPS Inverter

On different forums, I often find people asking for help in calculating the required turns for a ferrite transformer they are going to use in high-frequency/SMPS inverters.

Get Price

Calculation method of high-frequency transformer

The number of wires in a coil is not necessarily the number of turns. Only when the number of parallel windings is equal to 1, does the

Get Price

6 FAQs about [Number of turns of high frequency inverter]

What is a high frequency inverter?

In many applications, it is important for an inverter to be lightweight and of a relatively small size. This can be achieved by using a High-Frequency Inverter that involves an isolated DC-DC stage (Voltage Fed Push-Pull/Full Bridge) and the DC-AC section, which provides the AC output.

What is inverter frequency?

In today's world, inverters play a vital role in various applications, such as home solar power system, inverter for office use, inverter for van, etc. Central to their operation is the concept of an inverter frequency, which determines the rate at which the current alternates direction.

What is AC inverter frequency?

1. What is the frequency of AC inverter? An AC inverter frequency refers to the number of power signal fluctuations, typically measured in Hertz (Hz). In most regions, the standard inverter frequency for AC power systems is 50 or 60 Hz, representing the number of complete cycles per second.

What factors affect inverter frequency?

Several factors influence the inverter frequency, including the design of the power electronics, the configuration of the control circuitry, and the specifications of the utility grid. In grid-tied inverters, for instance, the inverter frequency is typically synchronized with the utility grid to ensure compatibility and seamless energy transfer.

What is the maximum inverter frequency?

The maximum inverter frequency depends on its design specifications, with most commercial models offering a maximum frequency between 10 kilohertz to megahertz.

What happens if you exceed inverter frequency limits?

Exceeding these inverter frequency limits can lead to various undesirable consequences, including component stress, overheating, reduced system lifespan, and potential safety hazards.

More related information

-

The inverter high frequency voltage becomes 50hz

The inverter high frequency voltage becomes 50hz

-

High frequency inverter parallel operation

High frequency inverter parallel operation

-

Does a high inverter frequency mean high power

Does a high inverter frequency mean high power

-

Austria high frequency power inverter

Austria high frequency power inverter

-

Lesotho high frequency inverter manufacturer

Lesotho high frequency inverter manufacturer

-

High frequency dual silicon inverter consumes electricity

High frequency dual silicon inverter consumes electricity

-

High frequency inverter life

High frequency inverter life

-

High frequency inverter is also a sine wave

High frequency inverter is also a sine wave

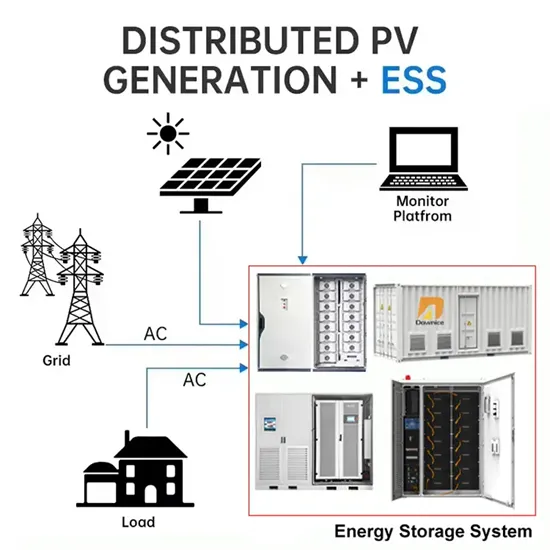

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.