Battery Power Applications Design Guide

Each circuit design provides constant current charging followed by constant voltage charging algorithm with automatic charge termination and battery temperature monitoring.

Get Price

Six System Architectures With Robust Reverse Battery

This application report highlights how the new LM74800-Q1 back-to-back power N-channel FET-based ideal diode controller with load dump protection simplifies the reverse battery protection

Get Price

How To Protect 48-V Batteries from Overcurrent and

The design process will be broken down into three main sections: Voltage Regulation, Overcurrent Protection, and Undervoltage Protection with Hysteresis. This design has design

Get Price

Overload Circuitry Protects Batteries and Power Supplies

A combination of current-sense amplifier, dual-comparator, and external CMOS switches can be used to prevent the damaging effects of a reversed-polarity

Get Price

LUNA2000-215 Series: Smart Energy Storage

Discover the Huawei LUNA2000-215 Series, a smart and efficient energy storage solution for your home. Enhance your solar energy system with reliable

Get Price

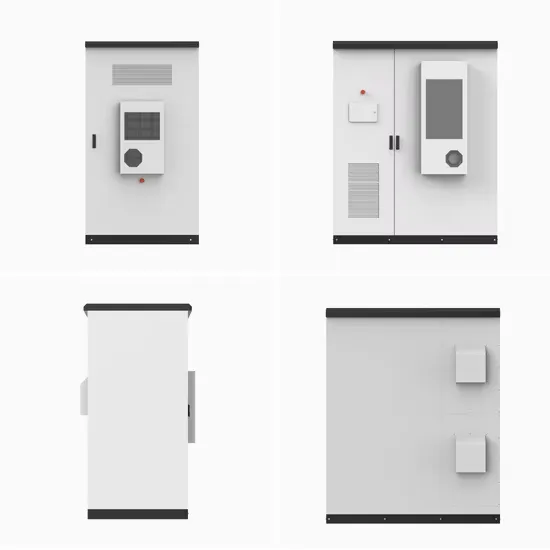

Battery Cabinets

The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 24Ah to 105Ah (C10). The battery cabinets are available in 5

Get Price

Overcurrent protection enables more efficient and reliable

Overcurrent protection allows the design team to manage their system thermal performance more eficiently and anticipate problems versus react to potential issues. There are many reasons to

Get Price

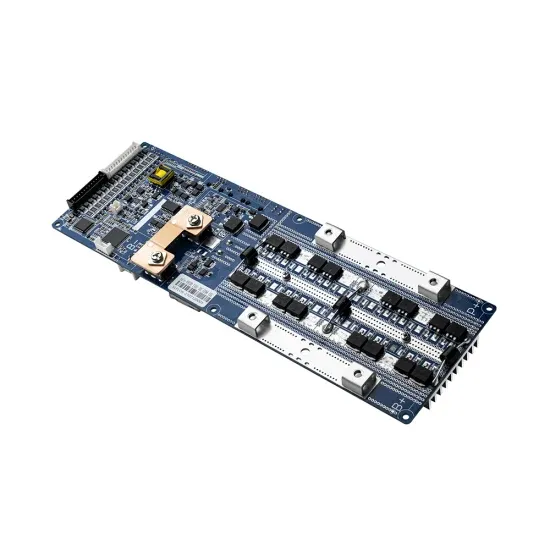

BMS Overcurrent Protection: Indispensable for Battery

This paper will introduce the concept of overcurrent protection, discuss the risks of not BMS overcurrent protection, and highlight the battery

Get Price

BATTERY ENERGY STORAGE OVERCURRENT

While Electrical Energy Storage is not new, the increase of power has brought new constraints and challenges for over-current protection devices. DC fuses must withstand a wide range of

Get Price

Automotive 12

1 System Description Automotive 12-, 24-, and 48-V battery power supply lines are prone to transients while running the system. Typical protections required for such a system are

Get Price

24 V DC overcurrent protection and power distribution

24 V DC overcurrent protection and power distribution This application example explains how 24 V DC can be protected, multiplicated and distributed in the I/O environment. Typical

Get Price

Simple Undervoltage and Overcurrent Protection for

Introduction To safely utilize lithium-ion or lithium polymer batteries, they must be paired with protection circuitry capable of keeping

Get Price

Overload Circuitry Protects Batteries and Power Supplies

A combination of current-sense amplifier, dual-comparator, and external CMOS switches can be used to prevent the damaging effects of a reversed-polarity battery or short-circuit load.

Get Price

Battery Charging Cabinet Solutions for Safer Lithium-Ion Battery

A battery charging cabinet is a purpose-built unit designed to store and charge batteries safely, particularly lithium-ion types. These cabinets often include built-in fire-resistant

Get Price

What Is Overcurrent Protection? Everything You Need to Know

Are you wondering what an overcurrent protection mechanism is and how it works? This guide explains it all, from basic understanding to advanced calculations, and more.

Get Price

Simple Undervoltage and Overcurrent Protection for Lithium-Ion

Figure 4 shows the modified schematic that provides overvoltage protection, undervoltage protection, and discharge overcurrent protection for two cells in series.

Get Price

Overcurrent Protection Circuit using Op-Amp

The circuit we are about to design will have an adjustable overcurrent threshold value and will also have an Auto-restart on failure

Get Price

BMS Overcurrent Protection: Indispensable for Battery Safety

This paper will introduce the concept of overcurrent protection, discuss the risks of not BMS overcurrent protection, and highlight the battery management system and battery

Get Price

Battery Power Applications Design Guide

Circuit protection is important at the level of the module, the battery rack, the dc panel (also known as the dc-array combiner cabinet), and the

Get Price

DESIGN FOR SAFE AND RELIABLE ELECTRICAL

With an unpredictable fault current the selection of the rating of the protection is quite challenging. The purpose of this document is to go more in depth in the analysis of the current delivered by

Get Price

Battery Energy Storage System (BESS) Electrical

The electrical integration design of a Battery Energy Storage System (BESS) is based on the application scenario and includes various

Get Price

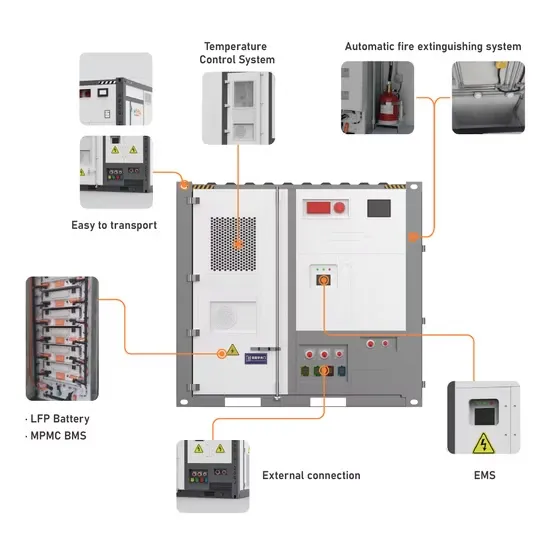

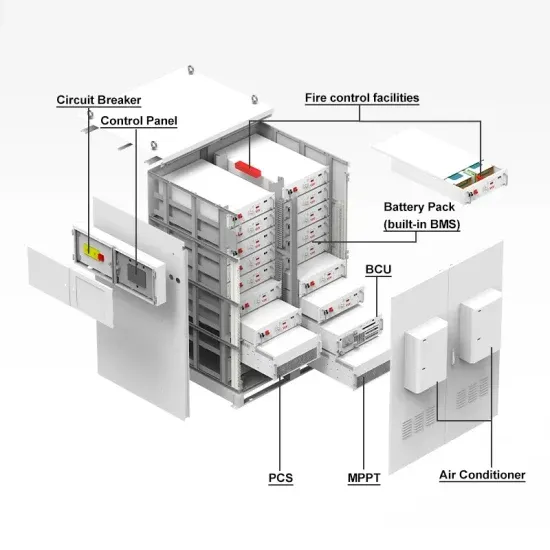

How to design an energy storage cabinet: integration and

The following are several key design points: Modular design: The design of the energy storage cabinet should adopt a modular structure to facilitate expansion, maintenance

Get Price

Which technology is best for your battery protection?

As protection FETs they naturally need to protect against electrical faults such as overcurrent, overvoltage, undervoltage, and short circuits. And for any battery powered device, protection

Get Price

Simple Undervoltage and Overcurrent Protection for

Figure 4 shows the modified schematic that provides overvoltage protection, undervoltage protection, and discharge overcurrent protection for

Get Price

Switching & Protection solutions for Battery Racks in Battery

Every battery rack requires adequate galvanically switching and protection against overcurrents caused by battery modules. Unlike in PV strings, the overcurrents caused by batteries can be

Get Price

How to Properly Protect a BESS Power Circuit from Overcurrents

Circuit protection is important at the level of the module, the battery rack, the dc panel (also known as the dc-array combiner cabinet), and the inputs to the power conversion

Get Price

Battery protection selection guide

Consequently, such batteries require special care in stressful conditions such as overcharge, undercharge, short circuits, overheat, etc. For that, Infineon ofers a wide range of battery

Get Price

FUSES AND OVERCURRENT PROTECTION DEVICES

HIGH SPEED FUSES ARE DIFFERENT FROM REGULAR STANDARD FUSES High speed fuses are used to protect semiconductor devices against overcurrent conditions. They are

Get Price

6 FAQs about [Battery cabinet overcurrent protection design]

How to protect a battery rack from overcurrents?

Every battery rack requires adequate galvanically switching and protection against overcurrents caused by battery modules. Unlike in PV strings, the overcurrents caused by batteries can be very high according to the battery technology.

What is overcurrent protection?

Overcurrent protection refers to the lithium battery in the power supply to the load, the current will change with the change of voltage and power, when the current is very high, it is easy to burn the protection board, battery, or equipment.

Why is battery overcurrent protection important?

However, the widespread use of batteries has also brought about current problems, where the presence of overcurrents can lead to catastrophic accidents such as equipment failures, fires, and even explosions. Therefore, overcurrent protection has become a key element in ensuring the safety of battery applications.

Do lithium ion batteries have overcurrent protection?

A similar issue presents itself when trying to incorporate overcurrent protection that is more sophisticated than a fuse, yet does not come bundled with unnecessary battery management functionality. Lithium-ion (Li-ion) and lithium polymer (LiPo) batteries have very similar electrical characteristics but differ in packaging.

Why is undervoltage protection important for lithium ion batteries?

To safely operate such a battery, the discharge current rate and battery voltage level must be monitored. Undervoltage protection is crucial when using lithium-ion batteries because if the battery is discharged below its rated value, the battery will become damaged and potentially pose a safety hazard.

What is an overcurrent protection trigger?

Overcurrent protection trigger: When the battery protection board detects that the current has exceeded the set safety threshold, it will trigger the overcurrent protection mechanism to avoid damage to the battery and equipment caused by excessive current. a.

More related information

-

Ireland lithium battery energy storage cabinet fire protection system

Ireland lithium battery energy storage cabinet fire protection system

-

Battery cabinet production design

Battery cabinet production design

-

Design of outdoor power battery cabinet

Design of outdoor power battery cabinet

-

Energy storage cabinet inverter battery environmental protection

Energy storage cabinet inverter battery environmental protection

-

Battery cabinet protection cabinet base station and price

Battery cabinet protection cabinet base station and price

-

Battery cabinet design requirements

Battery cabinet design requirements

-

Square battery energy storage cabinet design

Square battery energy storage cabinet design

-

How many layers of protection does the new energy battery cabinet have

How many layers of protection does the new energy battery cabinet have

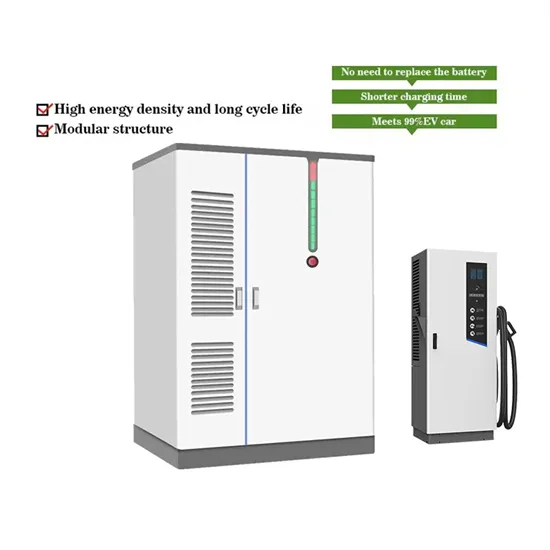

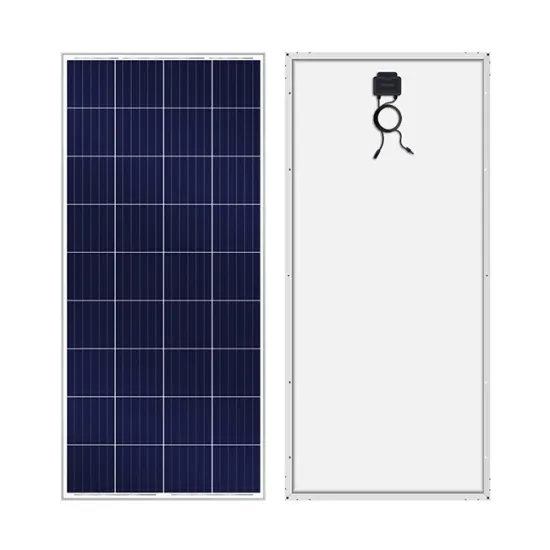

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.